Introduction

Material handling inside factories and warehouses has always been the lifeline of operations. From raw materials entering the facility to finished goods leaving for customers, one silent hero has kept the flow alive: the forklift or pallet truck. But times are changing. Manual forklifts and hand-operated pallet trucks are now being replaced with Forklift AMRs (Autonomous Mobile Robots) — also called Autonomous Pallet Trucks.

These are intelligent, software-driven, self-navigating machines designed for speed, precision, and safety. They don’t need a driver, they don’t make errors out of fatigue, and they adapt to dynamic warehouse conditions — making them the future of intralogistics.

This blog will answer every possible question you may have — what Forklift AMRs are, how they work, why they matter, where they fit best, and when they deliver maximum impact.

What Are Forklift AMRs (Autonomous Pallet Trucks)?

Forklift AMRs, often referred to as Autonomous Pallet Trucks, are AI-powered, self-driving forklifts that handle pallets automatically without human operators. They combine advanced navigation, safety sensors, and intelligent software to move, lift, and place pallets with minimal manual intervention.

-

Ground-to-Ground Movement: They can move pallets across the floor from point A to point B.

-

Ground-to-Height Movement: Many Forklift AMRs can also lift pallets into racks, shelves, or conveyors, functioning as stackers.

In short, whether you call them a Forklift AMR or an Autonomous Pallet Truck, they represent the next generation of pallet handling automation.

How Do Forklift AMRs & Autonomous Pallet Trucks Actually Work? (Technology Explained)

At the heart of these robots lies pallet detection — the single most important technology that makes them useful.

-

Pallet Detection:

Before picking a pallet, the robot must “see” and “understand” where the pallet is, what orientation it has, and whether it is safe to pick. This is achieved with a combination of:-

3D Vision Cameras

-

Lidar Sensors

-

AI Algorithms

-

Fork Alignment Systems

-

-

Navigation:

Robots use SLAM (Simultaneous Localization and Mapping) to move around without needing magnetic tape or fixed paths. They create and continuously update a digital map of the facility. -

Safety:

Equipped with 360° obstacle detection, emergency stop systems, and compliance with ISO/CE safety standards, these robots ensure safe operation even in human-heavy environments. -

Software Brain:

Platforms like Fleet Management Software orchestrate a group of robots — deciding who moves where, at what time, and in what sequence.

Why Are Companies Replacing Traditional Forklifts?

Manual forklifts are reliable, but they come with challenges:

-

High risk of accidents (forklifts are among the top causes of warehouse injuries).

-

Labor shortages and operator fatigue.

-

Lack of efficiency data (hard to track productivity).

-

Limited 24/7 utilization.

Forklift AMRs and autonomous pallet trucks solve these problems by:

-

100% safety compliance with built-in sensors.

-

Consistent operations 24/7.

-

Data-driven efficiency: every movement is tracked, analyzed, and optimized.

-

Scalability: you can start with 1 robot and grow to 100 with the same software system.

Discover how Forklift AMRs and Autonomous Pallet Trucks transform warehouse efficiency.

Download our free brochure for expert insights and trends!

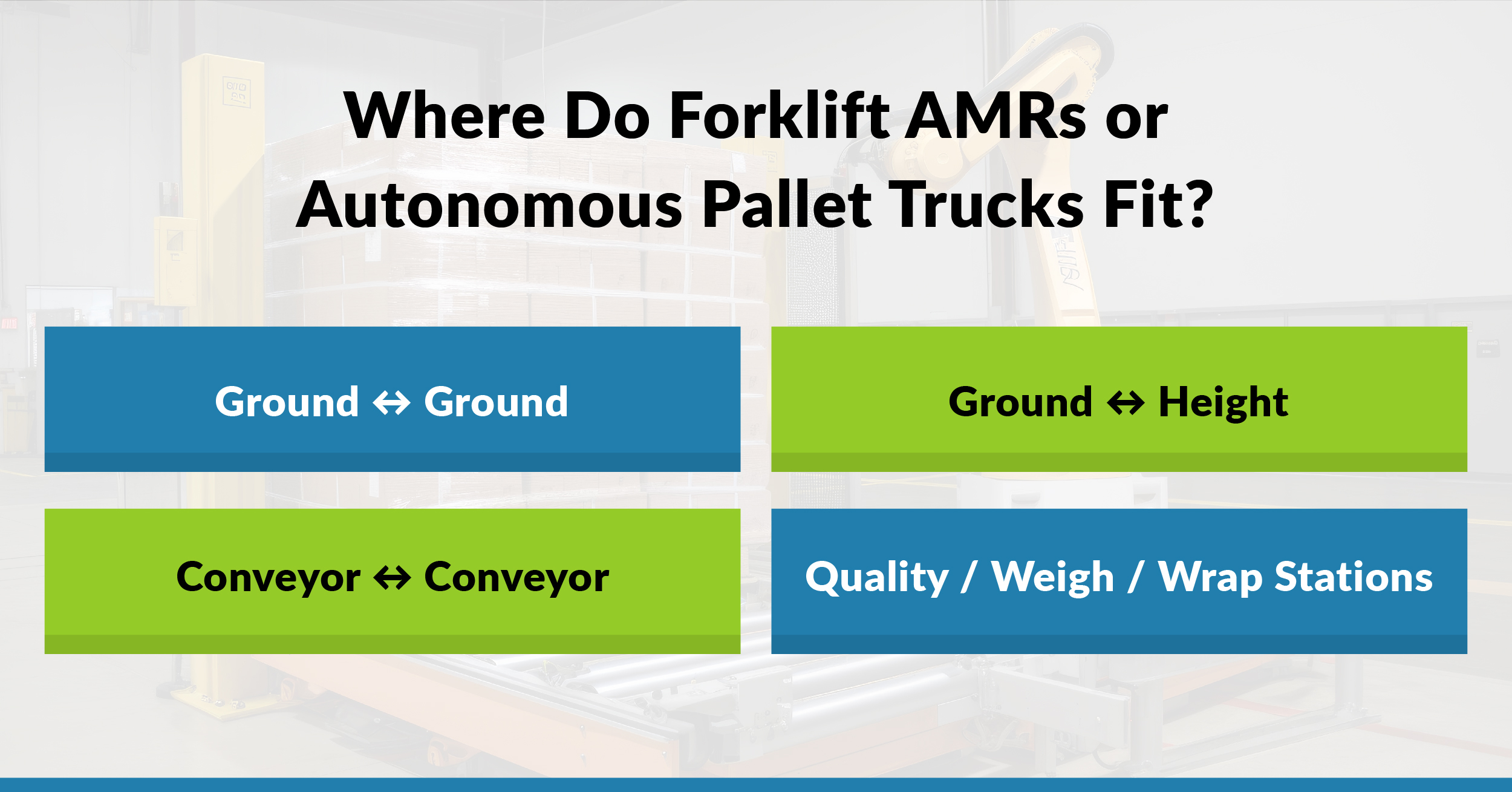

Where Do Forklift AMRs or Autonomous Pallet Trucks Fit? (Workflows Explained)

Forklift AMRs and pallet trucks are not “one-size-fits-all.” Their biggest strength is fitting into different workflows, seamlessly replacing or enhancing manual material handling.

-

Ground ↔ Ground:

The most common workflow. Moving pallets between floor positions, inbound areas, and outbound staging. -

Ground ↔ Height:

Forklift AMRs STACKER shine here — placing pallets into racks, flow stands, or height-based conveyors. -

Conveyor ↔ Conveyor:

Robots can pick pallets from one conveyor and place them onto another, with precision-controlled roller or lift-top interfaces. -

Quality / Weigh / Wrap Stations:

Robots act smart — waiting until the process (like weighing or wrapping) is finished, then automatically moving the pallet to the next stage.

In other words: No matter the material flow, there’s a workflow-fit for autonomous forklifts and pallet trucks.

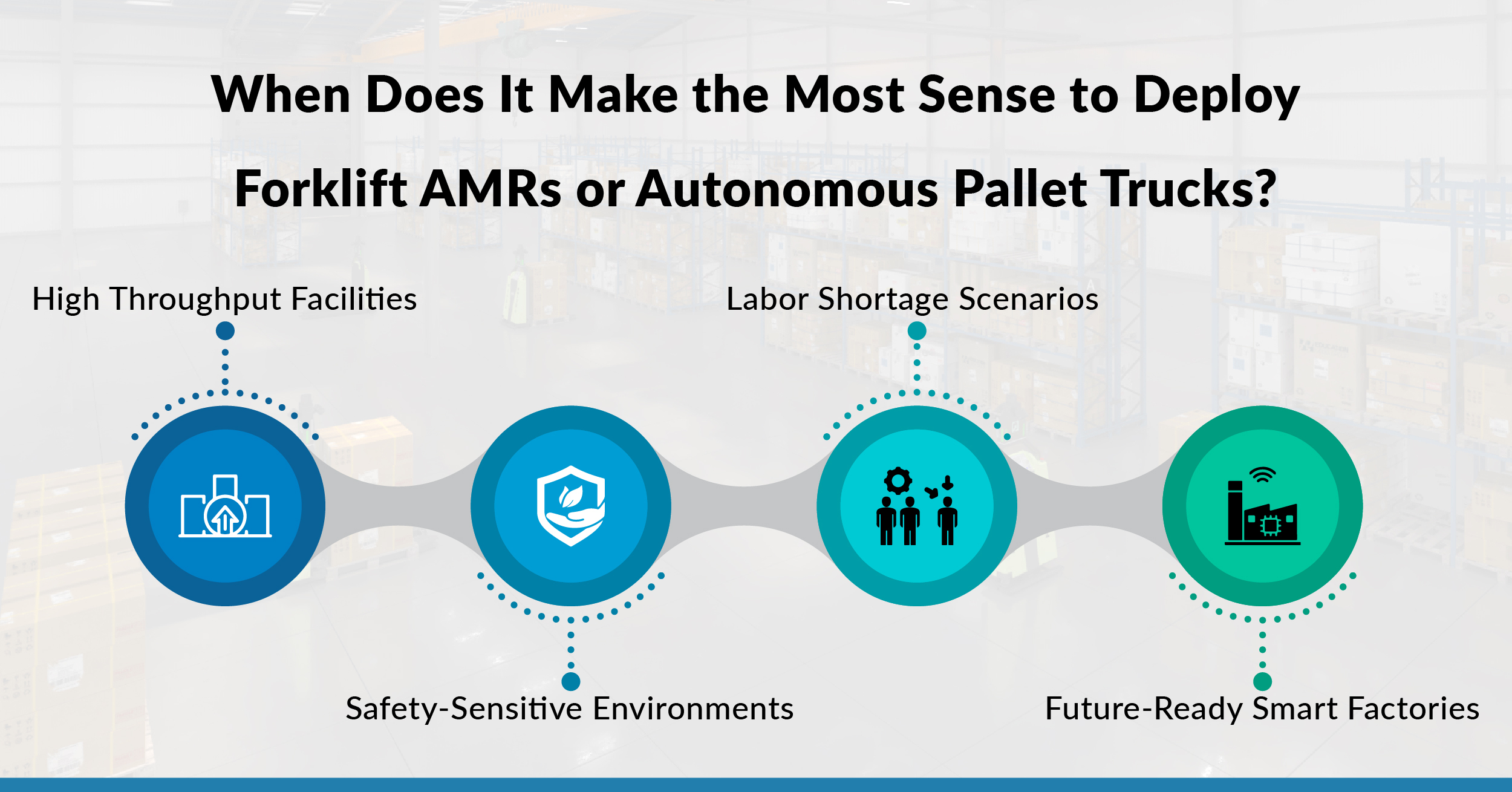

When Does It Make the Most Sense to Deploy Forklift AMRs or Autonomous Pallet Trucks?

-

High Throughput Facilities:

Automotive, FMCG, pharma, petrochemical plants — where pallet movements are constant. -

Safety-Sensitive Environments:

Plants handling heavy loads, chemicals, or where human-machine safety is critical. -

Labor Shortage Scenarios:

Areas struggling with trained forklift drivers. -

Future-Ready Smart Factories:

Companies moving towards Industry 4.0 and requiring intelligent automation.

Benefits That Go Beyond Cost Savings

-

Higher efficiency in material movement.

-

Accident reduction (as high as 100% in some deployments).

-

Predictable TATs (Turnaround Times) for pallet movements.

-

Zero fatigue and downtime.

-

Integration with WMS/ERP systems, ensuring automated task assignment.

This is not just about saving labor — it’s about transforming material handling into a predictable, safe, and data-driven process.

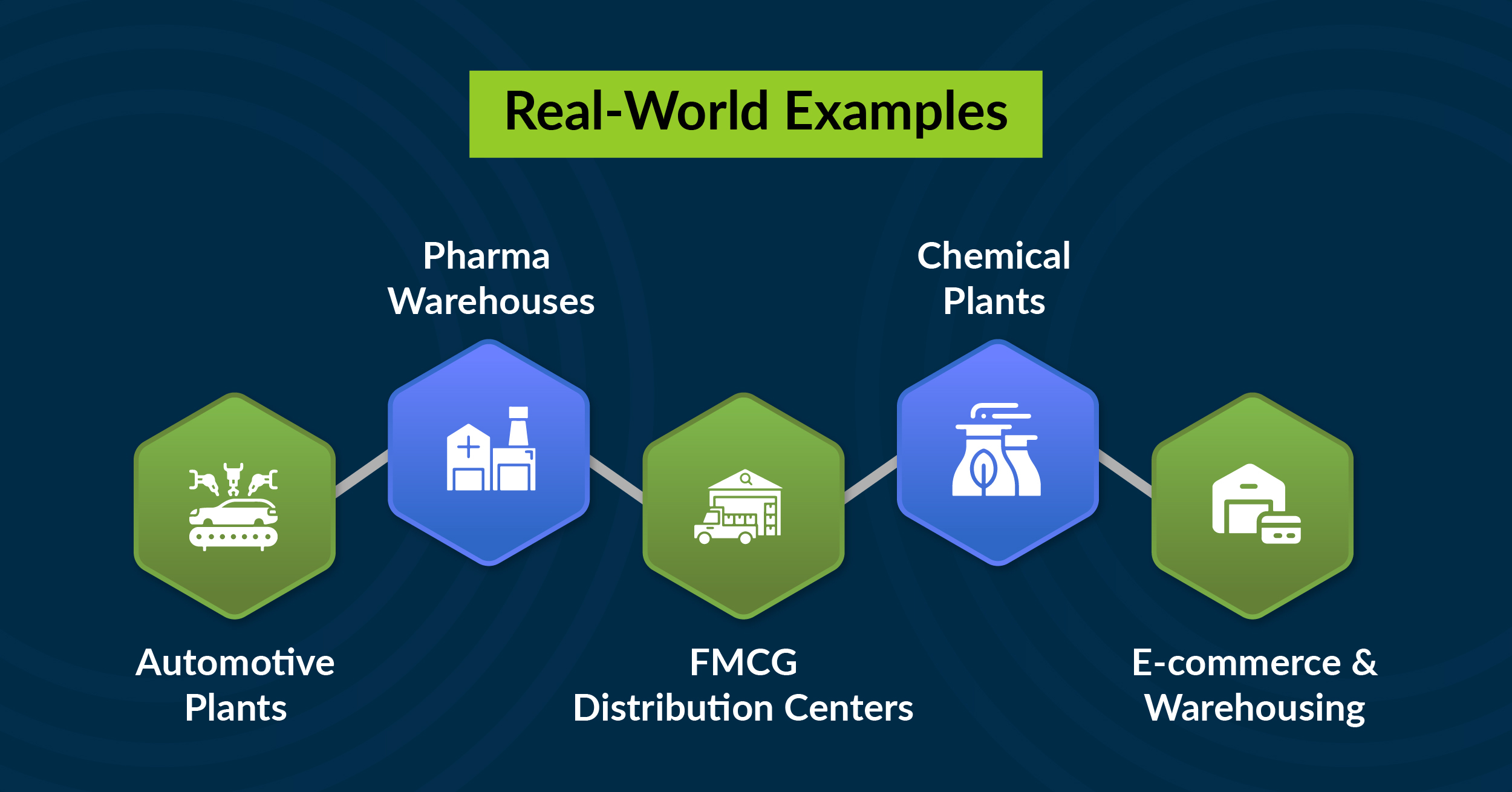

Real-World Examples

-

Automotive Plants: Forklift AMRs deliver raw materials to assembly lines, ensuring uninterrupted flow.

-

Pharma Warehouses: Autonomous pallet trucks maintain safe, contamination-free pallet movements.

-

FMCG Distribution Centers: Robots handle high-volume, repetitive ground ↔ ground and ground ↔ height transfers.

-

Chemical Plants: Safety-first deployment where human forklift accidents are not acceptable.

- E-commerce & Warehousing: Robots handle high-volume, repetitive pallet and bin transfers — from inbound to storage, storage to picking, and picking to dispatch — ensuring speed and accuracy in warehouses and eCommerce hubs.

Basically, any industry that moves a lot of materials daily.

The Future: From Robots to Robotic Intelligence

The next phase is not just about robots moving pallets, but robots making decisions.

-

Predicting demand in material flow.

-

Dynamic rerouting during congestion.

-

Multi-robot collaboration for faster throughput.

-

AI-driven optimization reducing idle time.

Forklift AMRs and autonomous pallet trucks are stepping stones towards self-orchestrating, intelligent intralogistics ecosystems.

Final Word

If forklifts were the workhorses of the 20th century, forklift AMRs or autonomous pallet trucks are the smart horses of the 21st century. They don’t just move pallets — they bring intelligence, safety, and efficiency to the heart of every factory and warehouse.

With pallet detection, flexible workflows, and software-driven orchestration, they answer every challenge traditional material handling faces.

👉 The question is no longer if robots will replace forklifts.

It is when you will make the shift.

Novus Hi-Tech, the leading manufacturer of Forklift AMRs and Autonomous Pallet Trucks, is driving this transformation by delivering advanced automation solutions that make warehouses and factories more efficient, safe, and intelligent. 🚀

👉 Ready to transform your material handling? Talk to our experts today and see how Novus Hi-Tech can future-proof your operations.

Frequently Asked Questions (FAQ)