The shift from the status quo in the automotive industry is happening within automotive automation. Increasing demands for efficiency, speed, safety, and innovation have prompted manufacturers to utilize automation – from robots to software-based command-and-control systems – so they can produce vehicles more effectively. Today’s car manufacturers conceptualize automation in a form that is unlike simply another technical fix. One can see how automotive automation is, from the last 10 years of technological evolution, becoming fundamental to modern automotive production.

What’s Driving the Adoption of Automation in Automotive Manufacturing

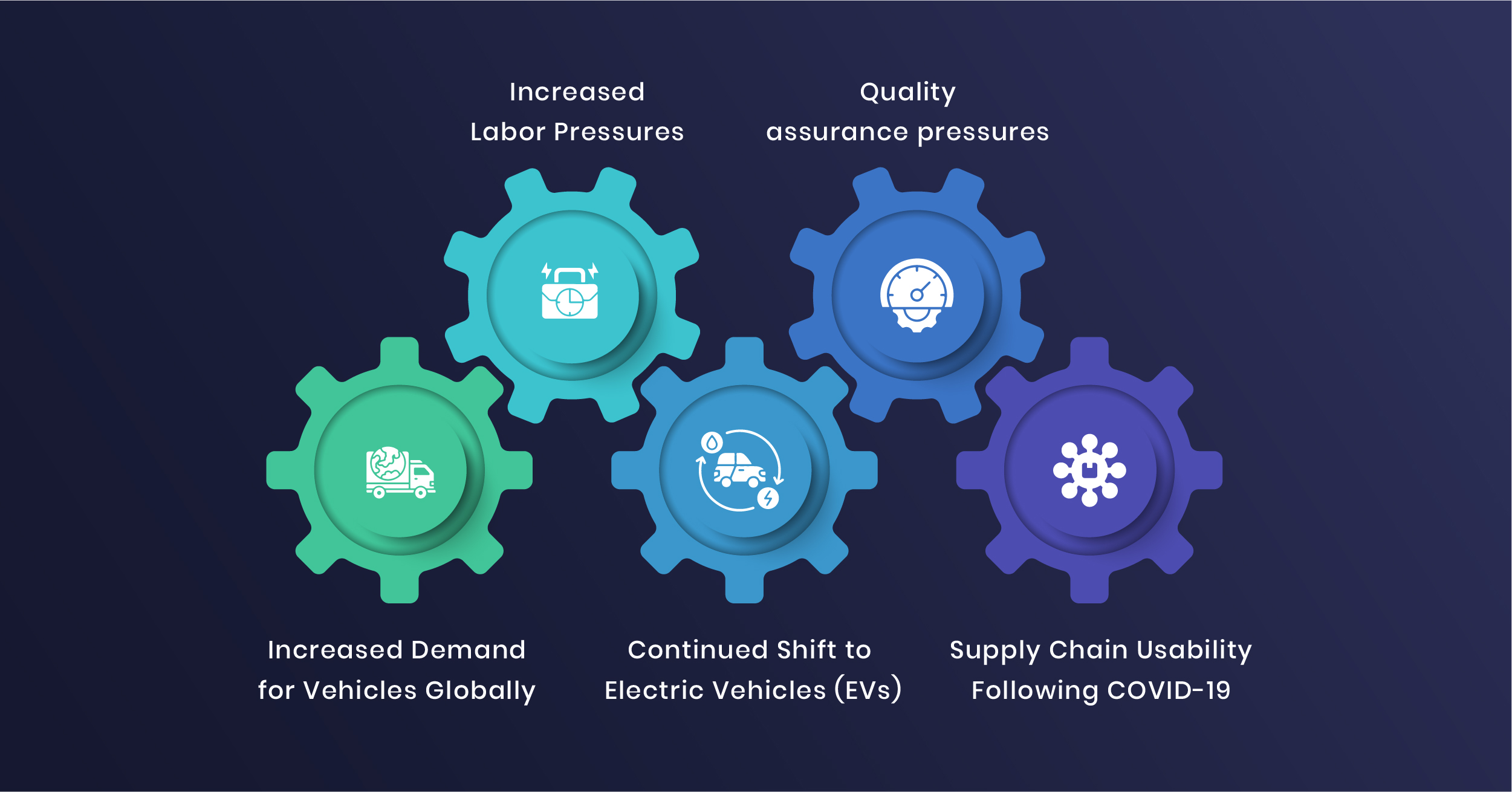

The following trends are accelerating automation in the auto industry:

Increased Demand for Vehicles Globally

As global markets grow, manufacturers will be squeezed to keep up the same level of production backlog and speed, but with no loss of precision.

Increased Labor Pressures

As good tradespeople, such as welders, finishers, etc., become harder to find, automated systems will be a requirement for manufacturers if they want to continue to produce with the same quality and productivity levels.

Continued Shift to Electric Vehicles (EVs)

EVs will bring an entirely new production process (like attaching battery packs) with several new moving parts, and by using automation, there is steady quality, safety, and consistency.

Quality assurance pressures

As more brands compete on reliability and customer experience, automation provides tighter tolerances and inspections with much less defects.

Supply Chain Usability Following COVID-19

The COVID-19 crisis has not only interrupted supply chains from the immediate cascading supply disruptions, but also inflation, and has led to less stable and/or flexible modes of production, so that car makers can identify alternative, change production, or increase or decrease capacity, or locate their assembly closer to their customers.

In the end, automotive automation is not an optional response but a strategic plan to accommodate increasing demand, unpredictable supply, and shifting consumer expectations.

Current Advantages of Automotive Automation

Manufacturers investing in automotive automation are already capturing significant gains. These include faster production cycles, consistent product quality, reduced manual errors, improved worker safety, and greater energy efficiency. Because the auto makers can automate tasks that are either repetitive and low-value work or driven by hazards for the workers, not only are they able to reduce labor costs, but it also frees worker time for higher-value work. Ultimately, they become leaner, sharper, and highly ranked manufacturing plants with additional margins.

Discover how Automotive Automation transforms smart factories.

Download our brochure for expert insights and trends!

Emerging Trends and Technologies in Automotive Automation

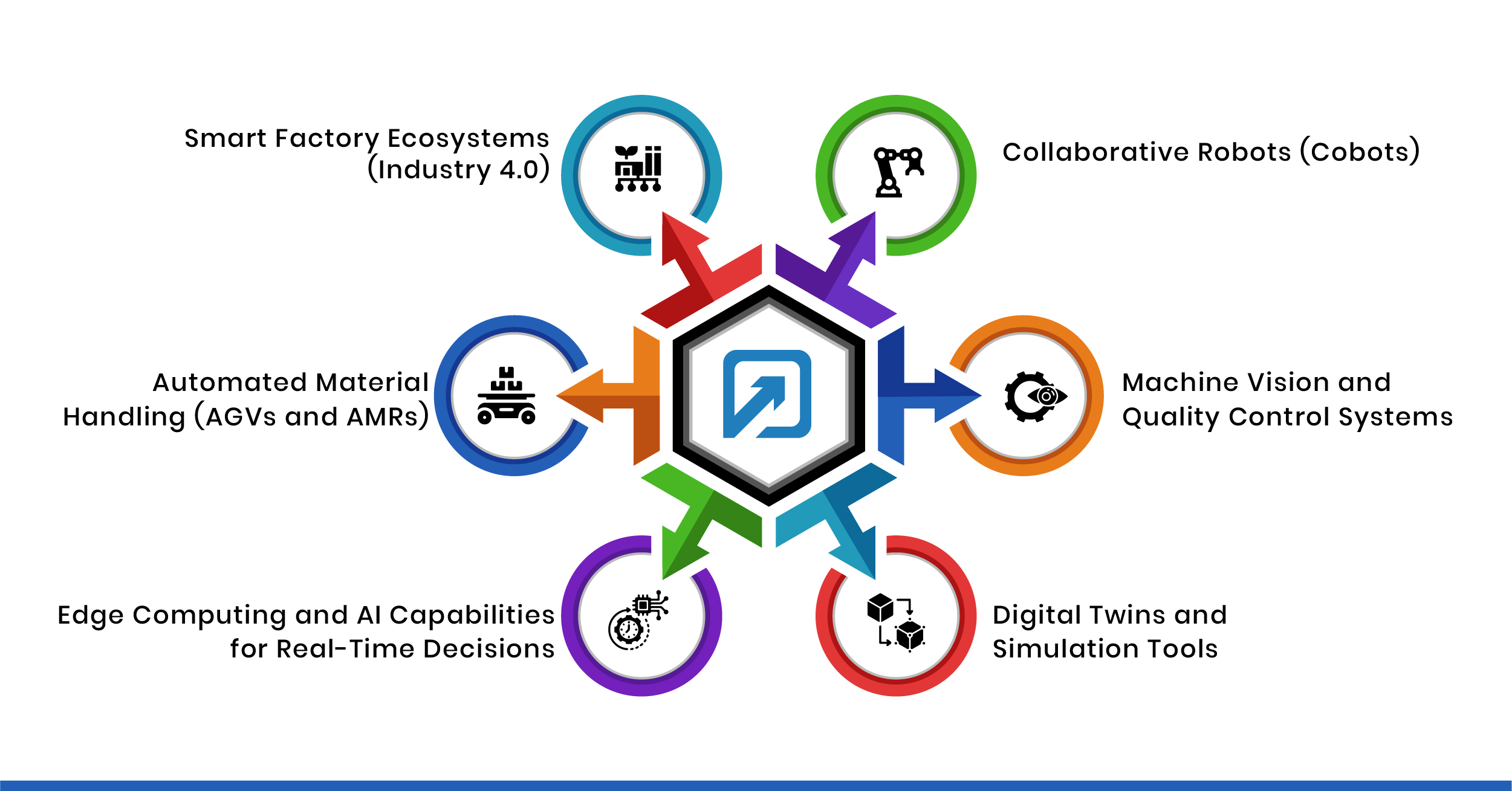

As automation in the automotive industry advances, several trends are reshaping production lines:

Collaborative Robots (Cobots)

Collaborative robots, or “cobots,” exist in tandem with human workers to perform task-related jobs such as screw driving and part placement. What differentiates cobots is that they can have their programming changed in minutes from one model line to another.

Machine Vision and Quality Control Systems

Machine vision systems using cameras can recognize defects in real-time, meaning you can identify a paint defect or alignment failure before the problem occurs.

Digital Twins and Simulation Tools

Digital Twins and simulation tools are virtual simulations of production lines that allow for real simulation of layout or process changes and thereby eliminate a great deal of trial-and-error on the shop floor.

Smart Factory Ecosystems (Industry 4.0)

A smart factory ecosystem is the combination of connected devices, interconnected processes, cloud-based data analytics, and IoT sensors that empowers manufacturers with real-time monitoring of their production and the ability to perform predictive maintenance, remote troubleshooting, and improved throughput.

Automated Material Handling (AGVs and AMRs)

Automated Guided Vehicles or Autonomous Mobile Robots navigate the shop autonomously, moving parts. With this automation, you are able to create efficiencies with logistics and reduce downtime.

Edge Computing and AI Capabilities for Real-Time Decisions

Edge‑based systems analyze data on‑site, allowing real‑time adjustments in assembly and rapidly identifying anomalies.

The Role of Smart Factories and Digitalization

A smart factory fuses automotive automation and digital connectivity. Machines enabled with IoT feed data at the machine-level into data analytics platforms in real time; AI capabilities create predictive maintenance, allowing for the prevention of failures; centralized dashboards provide real-time visibility into efficiency metrics. Smart factories utilize robotics, sensors, edge computing, and data analytics platforms to increase efficiency, reduce waste, and increase the speed of decision‑making.

How Local and Global Manufacturers Are Adapting

Across the globe, both established automakers and startups are using automation in automotive manufacturing to transform operations

Plants adapted for electric vehicles (EVs) are utilizing modular battery‑pack assembly stations, which at times can be mobile stations, giving them the ability to shift volume and meet demand and/or inventory levels.

Legacy OEMs are modifying existing plants with either robotic cells or with automated material flows and digital twins to maintain flexibility.

Tier-1 suppliers are adopting flexible, scalable automation systems that enable them to localize their supply chains while maintaining some degree of consistency and continuity in their products across multiple manufacturing sites.

This is an important point to consider: whether a company is manufacturing compact cars in Asia for urban dwellers or luxury SUVs in Europe for self-indulgent buyers, automation can provide volume and accuracy.

Sustainability and Automation Go Hand in Hand

Sustainability efforts in manufacturing align naturally with automotive automation. Automation systems are designed to decrease waste by making better use of raw materials, to achieve energy efficiency with intelligent robots, and to avoid expensive rework through real-time detection of defects. Because of consumer and regulatory pressures prompting industries to become green, automation may be the evolutionary mechanism for improvement and differentiation.

How Novus Hi-Tech Enables Smart Automotive Manufacturing

Novus Hi‑Tech is a trusted partner for automakers and tier suppliers seeking to modernize production through automation in the automotive industry. Novus Hi-Tech’s cumulative offerings, evaluated as total solutions, also include:

Custom automation systems – designed for unique and complex auto assembly processes, especially battery module installations, chassis welding, and pneumatic torque monitoring.

Collaborative AMRs / AGVs – to optimize in-plant logistics, inventory moves, and flows between stations.

Visual and sensor-based inspections – that measure quality at every stage of the assembly process, from measuring laser welds to checking paint surface quality.

Connected monitoring platforms – ultimate visibility into dashboards of bottlenecks, production KPIs, and alerts to diagnose predictive maintenance active states.

Legacy system integration – Novus Hi-Tech has expertise in combining and integrating old PLC-based equipment into Industry 4.0 architectures, allowing for upgrades to automated processes over time while maintaining production.

Conclusion

Mobile Production Stations and Modular Grid Systems

Novus Hi-Tech provides flexibility in the process thanks to mobile production stations and modular grid systems (see their factory-operation documentation) that allow manufacturers the flexibility to quickly and easily reconfigure production lines for new vehicle models or process changes. Customers can add production stations or remove them based on demand, utilize their footprint most effectively, and minimize the overhead time with virtually no changes to the layout of the plant when brought about, so the solution is perfect for EV models that have short production runs or localized variants based on after-market supply chain changes.

Novus Hi-Tech’s intelligent Agile systems enable OEMs and suppliers to transition from traditional mass production to a flexible smart factory system designed specifically for Industry 4.0.

FAQs

1. How to prepare for the future of artificial intelligence in manufacturing?

Start by investing in data infrastructure and devices that can connect–IoT sensors, digital twins, and edge analytics. Buy tools for your people that are AI-supported. The best method is small, proof of back to scale or buy to prove value back as a system, early, before you invest along the way!

2. How does automation improve quality in car manufacturing?

Automation eliminates variability by not allowing non-standard processes. Machine vision identifies part defects in real time; robots apply torque and pressure in a consistent and repeatable way; and analytics identify deviation as early as possible to eliminate defects and reduce rework and scrap.

3. What role do mobile robots play in automotive production lines?

Mobile robot solutions–(AGVs and AMRs)–are used for delivering materials quickly, help eliminate conveyor bottleneck impacts, and result in flexible, modular stations. They are a key component of just-in-time production, which makes agile factory layouts fast and flexible.

4. How does Novus Hi-Tech support automation integration in legacy systems?

Novus Hi‐Tech is able to provide integration services for retrofitting aging machines to smart controls. The integrated solutions translate to bridge layers between legacy PLC systems and new IoT platforms meaning factories are able to upscale incrementally instead of going dark. The modular grid and mobile station designs allow legacy lines to scale automotive automation.