Safety is the cornerstone of any successful manufacturing or warehousing operation. Factories or warehouses have inherent risks as part of normal operation. When you have heavy machinery, moving equipment, and stacked inventory, there is an inherent risk. Safety in the warehouse is much more than compliance—it’s about the people, the equipment, and the efficiencies.

Through investment in solid, safety programs in a factory and warehouse operation, reductions in accidents can be s, en; increases in productivity; and a work culture where team members prioritize safety. Let’s face it, Factory Safety is a serious business – let’s talk about why Factory Safety is important, and how to enhance that safety.

Why Manufacturing and Warehouse Safety Matters

Both factory safety and safety in a warehouse environment have an element of risk that may injure a worker and adversely affect processes. If appropriate safety measures are not in place when operating with a factory and warehouse system, a company could be held liable for the legal and financial problems that may follow.

Here are the reasons why safety regarding the industrial factory system is so important:

- Less risk of serious injury to workers. Each measure of safety we take reduces risk to workers, in terms of fewer slips and falls, safer use of equipment, and fewer material handling accidents. There will be safer placement of equipment and workers around the factory floor to minimize workers being injured by manual equipment use.

- Less delays to production, less downtime because of equipment breakdowns, and less wasted inventory. If we can maintain a safe work environment, we can help keep our processes moving forward wilow-costost in production delays.

- Allows companies to maintain the following safety regulations. By following safety rules and procedures, we wholly avoid huge legal and financial repercussions.

- Permits companies to promote a culture of safety as a part of the ongoing process. A culture of safety allows for safety awareness to take place in each area of daily accountability. This does include risk mitigations from not only factory safety but also safety in the warehouse.

Discover how to enhance safety in factory and warehouse operations.

Download our free brochure for expert insights and trends!

Daily Safety Tips for Factories and Warehouses

Establishing and implementing a daily safety habit system is an easy yet very effective way to prevent incidents and improve health and safety in a warehouse working environment. Here is a list of unsafe working conditions that teams can practice daily safety habits about:

– Report unsafe working conditions immediately to a person of authority.

– Operate machinery and equipment per safe work practices.

– Always wear appropriate personal protective equipment (PPE), including high-visibility clothing.

– Keep workspaces, walkways, and emergency exits free and clear of obstruction at all times.

– Eliminate or minimize slip, trip, and fall challenges in manufacturing and storage environments.

– Follow safe work practices when handling hazardous materials to protect others.

– Store tons of inventory securely to prevent accidentally dropping items and causing injury.

– Use safe lifting techniques when manually handling bulk materials when it is practicable.

– Store flammable materials properly to mitigate flames and avoid the start of fire.

– Regularly stop and take breaks to not only recharge but also secure a level of concentration to prevent fatigue.

Practicing all of these simple daily habits can increase safety levels in manufacturing environments while eliminating hazards in Industrial Factory Safety operations.

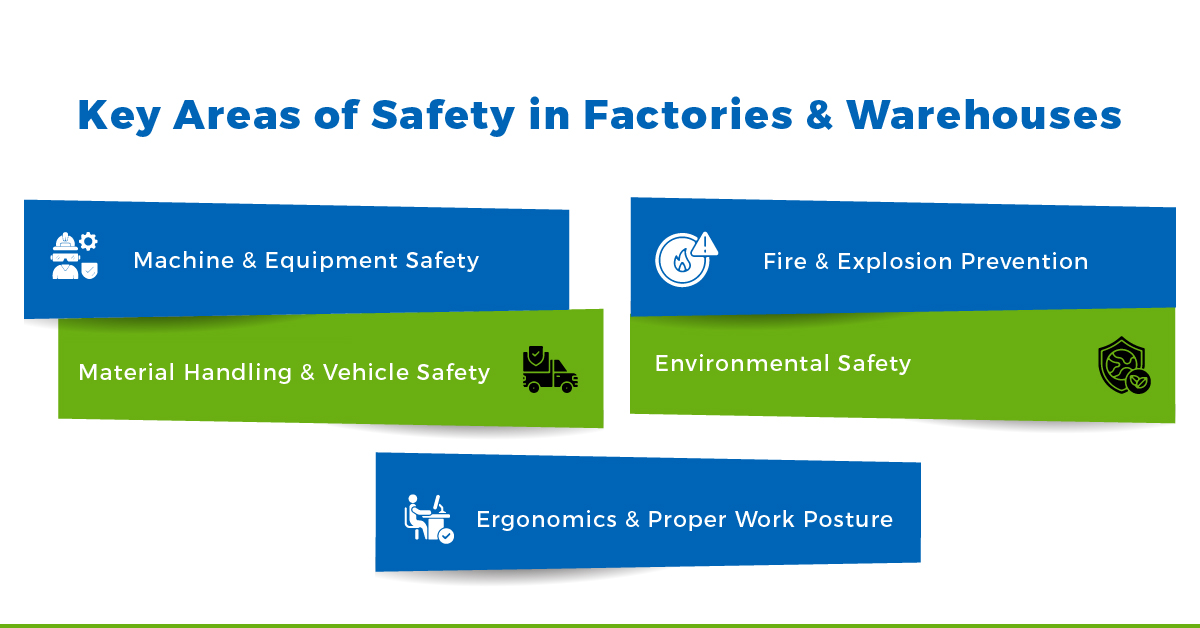

Key Areas of Safety in Factories and Warehouses

To develop a solid safety framework, organizations must focus on several core areas that impact safety in both factory and warehouse processes:

Machine and Equipment Safety

Machine maintenance and safety checks must be performed to help ensure machines function as intended. Proper functioning of machines is critical to decreasing the likelihood of accidents caused by machine malfunctions.

Material Handling and Vehicle Safety

Ensure all vehicles, including forklifts, pallet jacks, or any other conveying systems, are operated safely. It is important to have guidelines in place to avoid collisions between workers and vehicles or materials.

Fire and Explosion Prevention

Adequate fire safety systems, safe storage of flammables, and emergency evacuation plans for all employees to follow are required to avoid accidents.

Environmental Safety

Adequate ventilation, temperature control, and clean air standards help maintain a safe working environment, particularly in safety in warehouse settings.

Ergonomics and Proper Work Posture

Whether on an assembly line or stocking warehouse shelves, correct posture and ergonomic tools reduce strain and long-term injuries.

Warehouse-Specific Safety Focus

Although there is considerable overlap in many safety procedures, safety for warehousing operations does require some additional considerations:

Safe stacking and shelving: Goods that are improperly stacked have the potential to fall, creating the risk of injury and product loss.

Proper labelling and organization: Proper labelling contributes to retrieval efficiency and decreases the likelihood of accidents caused by misplaced materials.

Regular checking of warehouse racking systems: Noticing racking problems sooner rather than later could result in the prevention of very serious structural failures.

Traffic management for pedestrian and vehicle traffic: Designated walk pathways for movement will restrict vehicle zones and minimize the risk of accidents.

Proper lighting: Well-lit storage areas will help to prevent collisions, trips, and either dropping or mishandling goods.

In a manufacturing and warehousincontexton, the implementation of all or a portion of these safety measures will help streamline the process and keep the operations safer.

How Novus Hi-Tech Supports Factory and Warehouse Safety

At Novus Hi-Tech, we are committed to improving industrial factory safety and warehouse safety through intelligent technology-focused solutions.

Our solutions include:

- Auto Intralogistics: eliminates manual handling risks through automation in the movement of material.

- Robotic Material Handling: eliminates human handling in heavy lifting, thereby improving factory safety

- Vision Inspection Systems: proactively manage defects/hazards during the workflow

With Novus Hi-Tech’s state-of-the-art technology solutions, companies can improve factory safety protocols and safety in warehouse practices that create a safer and more efficient supply chain.

FINAL THOUGHTS

Protecting factory and warehouse operations regarding safety is not just a compliance concern; it represents an obligation to employees, organizations, and society as a whole. When organizations continually invest in safety aspects of factory processes, warehouse-specific operations, and new automation technologies (helpfully provided by organizations such as Novus Hi-Tech) that reflect industry-standard safety procedures, they set themselves up for a sustainable approach to growth and success.

Also, keep in mind that safety is a process, not a goal. Continuous training, thorough audits, and a willingness to modify safety practices will keep your teams and operations safe.

FAQs

Q1. What are the best practices for eliminating warehouse vehicle/pedestrian accidents?

By providing walking paths, signage, mirrors at crossovers, and speed limits on vehicles, you will help mitigate the risk of collision.

Q2. How often should safety audits be conducted in a manufacturing plant?

Internal inspections monthly, pending safety, and overall thorough audits yearly can help guarantee an effective factory safety program.

Q3. How does automation contribute to workplace safety?

Automation alleviates some of the physical workload associated with manual handling, reduces the worker’s exposure by taking away the worker from a hazardous process, and offers a higher level of accuracy. All of these improve safety in an industrial factory setting.

Q4.What should I include in a warehouse safety checklist?

The warehouse safety checklist contains the availability of personal protective equipment (PPE), the accessibility to emergency exits, the operation of fire safety equipment, the presence of safety signage, records of equipment inspection, and separation of vehicle and pedestrian activities.