The rapid expansion of warehouse and factory automation has brought autonomous mobile robots (AMRs) far into the operational landscape. AMRs are intelligent devices to facilitate changing workflows, reduce costs, and enhance efficiencies. The autonomous mobile robot market is appropriately on a global growth path, and companies are looking to identify the right AMRs to allow an operation to function efficiently (getting it right is important, as it will facilitate safer operation today, and leave the operation better prepared for growth shortly).

Novus Hi-Tech is a trusted partner in the autonomous mobile robot space and continues to implement autonomous mobile robot solutions across a variety of industries. Its AMR solutions show scalability, inherent safety, and suitability regardless of the integrated operational environment – that is, increased productivity gains and staying competitive!

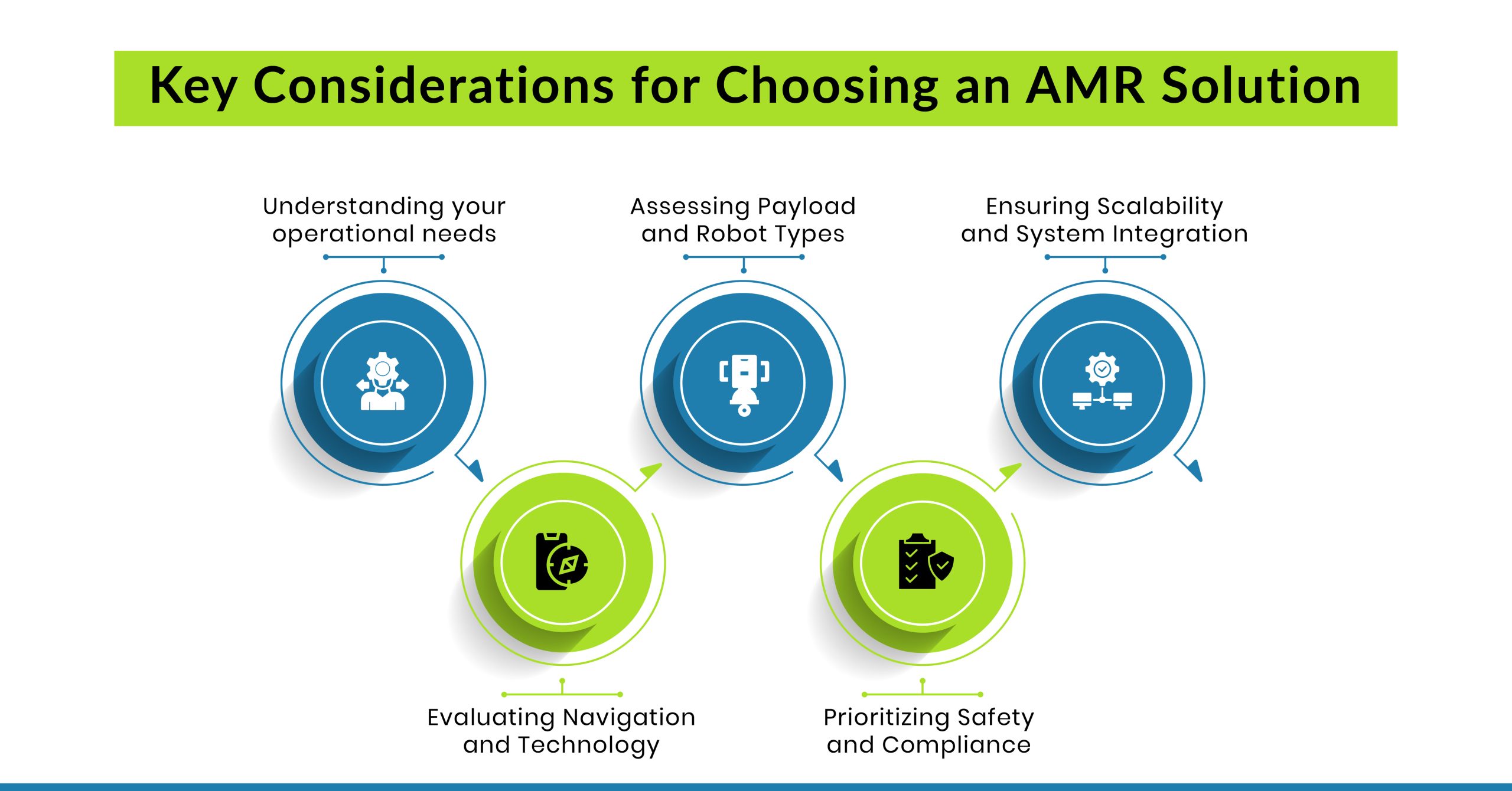

Key Considerations for Choosing an AMR Solution

-

Understanding your operational needs

A successful automation journey starts with a solid understanding of what the business needs in automating operations. The ideal AMR solution depends on many factors, such as workflow design, facility design, and demand throughput. For example, a high-volume e-commerce warehouse may care little for slow-moving AMRs or order fulfillment, but if the same warehouse were a manufacturing plant with materials to be moved, the same issue would be center front.

Thinking about AMRs in conjunction with needs and operational objectives will deal with unnecessary complexity and ultimately give the most benefit to the robots, augmenting productivity, not slowing it down.

-

Evaluating Navigation and Technology

The greatest consideration with any mobile autonomous robot is, quite candidly, the navigation system. Autonomous mobile robots use fantastic technologies like LiDAR, vision systems, or AI-based mapping, which allows the AMRs to move effectively and safely in unpredictable environments while performing their operationally purposeful and predictable tasks.

Robust navigation enables businesses to minimize downtime and reduce interruptions, allowing employees (and increasing robots) to focus solely on conducting their duties to move materials, even as humans and robots service very difficult working environments. Companies that conduct due diligence and understand the value of advanced navigation features offered in AMR solutions will come away from the research stage significantly more informed and support seamless task execution.

-

Assessing Payload and Robot Types

There are several different types of AMRs, from smaller-sized robots that are better for light picking to larger AMRs that are capable of transporting heavy pallets. Organizations need to have a firm grasp on the payload movements needed in order to select an AMR option, as well as the types of robots that fit their workplace environment.

To provide a couple of examples:

- E-commerce and Retail Fulfillment Picking Robots

- Logistics and Warehousing Pallet Movers

- Manufacturing Tugger AMRs for transporting materials on the floor.

It is always best to choose robots that meet verified load capacity to maintain operational constant efficiency, and to help organizations avoid unnecessary costs for capabilities that were not justified.

-

Prioritizing Safety and Compliance

As AMRs start to become a more permanent aspect of workplaces, we have to think safety first. Each mobile autonomous robot should have adequate safety measures like obstacle detection, automatic braking, and emergency stop features that help protect our workers.

When we incorporate safe robots, we are not only protecting workers but also protecting organizations from compliance with regulatory authorities.

-

Ensuring Scalability and System Integration

It is important to address the future need for AMRs to be scalable for future growth, and for them to be compatible with existing systems (such as warehouse management software). Emphasize that flexible solutions can easily adjust to constantly changing demand and integrate seamlessly to avoid operational silos.

Discover how the right Autonomous Mobile Robot (AMR) solutions drive business efficiency.

Download our free brochure for expert insights and trends!

Why Choose Novus Hi-Tech for AMR Solutions

Novus Hi-Tech is a world-class provider of intelligent AMR solutions designed to integrate with today’s business solutions. Their product offerings include intelligent robots with advanced navigational systems, numerous payload options, and a no-limits system compatibility.

Some of the key differentiators that Novus revolutionizes are:

- Safety: Every solution is built on the premise of safety.

- Scalability: Designed for your business as it exists now, but built to allow for growth into the future.

- Integration: Adapts to your existing IT ecosystem and environment.

- Expert Involvement: Expertise to drive the best ROI/efficiencies.

As the autonomous mobile robot market grows and matures, Novus Hi-Tech is prepared to help your business stay one step ahead!

Conclusion

Choosing an appropriate AMR solution is a big-picture decision and strategy that will impact the functionality and operation today and in the future. When making the decision, companies should consider the compatibility with other operational requirements, prestigious navigational technologies, payload capacity, robust safety standards, and compatibility with current processes.

Novus Hi-Tech has an offering of a unique autonomous mobile robot solution that, respective of the above, provides real value. Rather than like you are manually working with Novus, it is a matter of being more productive, safe, and scalable.

If you are ready to improve and streamline the operation of your warehouse or factory, give Novus Hi-Tech a call today to discuss the unique AMR solutions that are right for your company’s growth!