The manufacturing environment has never been more demanding than it is today, with a greater emphasis on precision, productivity, and automation. And then there are various types of industrial robots, a new and revolutionary technology that is changing how Indian factories are managed. Whether through automated functions that relieve workers from repetitive work, as well as other types of robots that help make the processes smarter, industrial robots are the way of the future for every modern industrial activity.

Novus Hi-Tech provides a new revolution to branding in India’s robotics ecosystem. Novus Hi-Tech delivers new, innovative, scalable automation systems; there are now various types of industrial robots, as part of safer, faster, and more productive operations.

Types of Industrial Robots

If you’re interested in getting a bit deeper into robotics, the next thing to learn is about the types of industrial robots found on the assembly and remote warehouse floors:

- Stationary Robots – Generally, stationary robots have a fixed location, generally for welding, painting, or assembling parts, where certain measurements must be made.

- Autonomous Mobile Robots (AMRs) – Intelligent self-driving systems that can create a detailed, or furthermore, dynamic plan for managing, organizing, or delivering materials/products while avoiding contact with humans.

Even though all industrial robots offer lucrative advantages to the manufacturer, all of them are successful with cost reductions, improved safety for the people, and real-time optimization.

- Automated Guided Vehicles

AGVs are essentially driverless vehicles designed to move materials within facilities. Unlike traditional forklifts or carts that require human operators, AGVs operate autonomously with programmed routes and smart navigation.

Articulated Robot Arms

Robot arms are likely the most versatile type of industrial robots; they use several joints, have a great working envelope, and have the ability to mimic the movement of a human arm. This is useful for applications like assembly, welding, and material handling.

In the industry, articulated robots are working in complex workflow automation that requires precision and programmability, which are intended to reduce errors.

Cartesian Robots

Cartesian robots are linear-motion robots that have motion back-and-forth in the following three directions: X, Y, and Z. They are probably the simplest robots available, and work successfully in applications with precise and repeatable motion, working agents, for example, 3D printing, pick-and-place, and CNC Machining.

The Cartesian robot is one of the simplest and cheapest types of industrial robots, and is a very common type of robot in use worldwide in the electronics and packaging industry.

SCARA Robots

SCARA (Selective Compliance Assembly Robot Arm) robots are compact, fast, and well-suited for high-speed assembly manufacturing lines due to their unique horizontal movement capabilities. They are typically used for pick and place and screw attaching applications.

The SCARA robot is the robot style commonly recommended for manufacturing that wants to increase speed in a robotic assembly station.

Delta Robots

Delta robots are lightweight, high-speed robots intended to handle delicate components quickly. Their spider-like construction allows them to perform precision tasks, or sorting and packaging tasks. Delta robots are utilized throughout the food, pharmaceutical, and electronics industries.

If your application includes quickly handling delicate components, Delta robots are one of the most versatile types of industrial robots.

Co-bots (Collaborative Robots)

Co-bots (collaborative robots) are industrial robots that can work safely adjacent to people. Co-bots are equipped with a suite of sensors and safety functions that allow them to work along with workers performing the same tasks and enhance human-robot collaboration.

Co-bots are a practical option as manufacturers are moving to the next step of automation, and starting with co-bots is arguably the best way to go, as it does not really change the way you are working. Co-bots provide a mindful and ethical approach towards automation, which is especially important for organizations that do not want to be demonized as the “bad guy” in the time of automation and delivering an “ethically void” situation.

AGVs (Automated Guided Vehicles) from Novus Hi-Tech provide the same complement to co-bots as they automate the handling and logistics of materials and goods in factories and warehouses, too. AGVs and co-bots work together in a smart, automated, and scalable environment where a human worker does not have to repeat the same tasks and motions of goods, while humans, the knowledge workers, exist in the context of thinking, deciding, and working on high-value tasks.

Discover how various Industrial Robots enhance manufacturing productivity.

Download our free eBook for expert insights and trends!

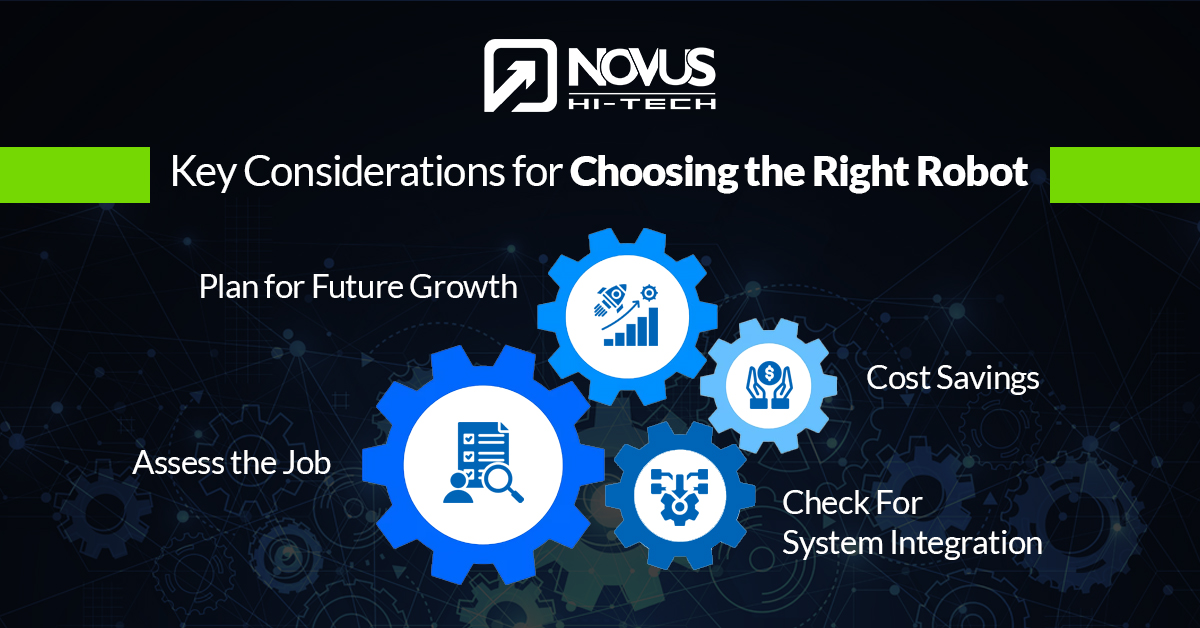

Key Considerations for Choosing the Right Robot

There are many kinds of industrial robots to choose from, so do your research and think carefully about it. Here are four main things to consider:

- Assess the Job

Is the application speed, accuracy, or force? The industrial robot you choose should match the job complexity.

- Plan for Future Growth

Review all the types of industrial robots that can grow along with your company and allow for increased or revised workforce or future automation changes.

- Check For System Integration

Make sure that your advanced robot can be integrated into your ERP, WMS, or control systems; this will help reduce losses and unplanned downtime, and allow productivity to run as smoothly as possible.

4. Cost Savings

Don’t just think about the purchase price; think about the total cost of the robot, and ask yourself how much they could save you in terms of decreased labour, energy, and increased outputs.

Novus Hi-Tech’s Robotic Solutions

At Novus Hi-Tech, we provide more than machines – we provide transformation. Our robotic solutions can handle any of the use cases from shop floor automation to smart warehouse automation, enabling manufacturers to leverage all forms of industrial robots.

Whether this is your first time investing in robotic integration or scaling your automation, we have dependable, future-ready options that fit your environment.

👉 You can find Novus Hi-Tech’s robotic solutions in our product catalogue or on our website.

Explore:

Conclusion

The types of industrial robots that are available today, such as collaborative robots (cobots), autonomous mobile robots (AMRs), or, of course, articulated industrial robot arms, are paving the way for an intelligent and more resilient future of manufacturing in industry. As each type of industrial robot comes with its respective benefits, ranging from improving safety and productivity, we can unequivocally conclude that we are at the forefront of a period of change.

Novus Hi-Tech is thrilled to be leading the way to deliver intelligent automation with efficient, scalable automation solutions for your success!

📩 Are you ready to innovate your operations? Speak to Novus Hi-Tech about a personalized consultation!

marketing@novushitech.com