Enhancing Efficiency and Safety in Industrial Operations

Material handling plays a critical role in getting the job done right the first time and efficiently among companies today with their fast-paced industrial landscapes, emphasis on safety, and importance of efficiency. Material handling equipment can be divided into several categories and benefits manufacturing and distribution in terms of operational excellence.

Understanding Material Handling Equipments

Material handling equipment is a tool that helps in transporting materials like vehicles, spare parts, appliances and accessories from one place to another for storing, controlling and protecting product in any stage of production from damages. This equipment is very crucial and necessary to limit the workplace injuries, reduce product damage and enhance productivity.

Discover how various Material Handling Equipment boosts operational productivity.

Download our free brochure for expert insights and trends!

Different Kinds of Material Handling Equipment

To efficiently conduct operations, there are many different kinds of material handling equipment required. Here’s an overview:

1. Storage and Handling Equipment

These equipments store or buffer materials at times when they are not being moved.

Examples:

- Pallet Racks: These store materials on pallets in horizontal rows.

- Shelving Systems: Small products or parts that can be accessed easily.

- Bins and Drawers: Suitable for arranging small parts and pieces.

Benefits:

- Conserve space.

- Enable easy stock checking.

- Increase access and orderliness.

2. Bulk Material Handling Equipments

- For handling bulk material such as ores, grains, coal, and sand, some of the equipments are the following,

- Conveyors: Transfer material by constant motion in a straight course.

- Stackers: Used for the stacking of bulk material

- Bucket Elevators: For vertical elevation of bulk materials.

Benefits:

- Enhance material-handling speed.

- Save labor.

- Minimize material damage.

3. Industrial Trucks and Vehicle

These are products intended to move materials along various routes. Examples include:

- Forklifts: They are employed for lifting and moving materials over a short distance.

- Pallet Jacks: They are hand equipment used in the moving of pallets

- Order Pickers: They find use in warehouses where a person is needed to access items held on tall shelves.

Benefits:

- It results in flexibility in movement.

- It ensures efficiency in loading and unloading.

- It helps in minimizing the risk of injury due to manual handling.

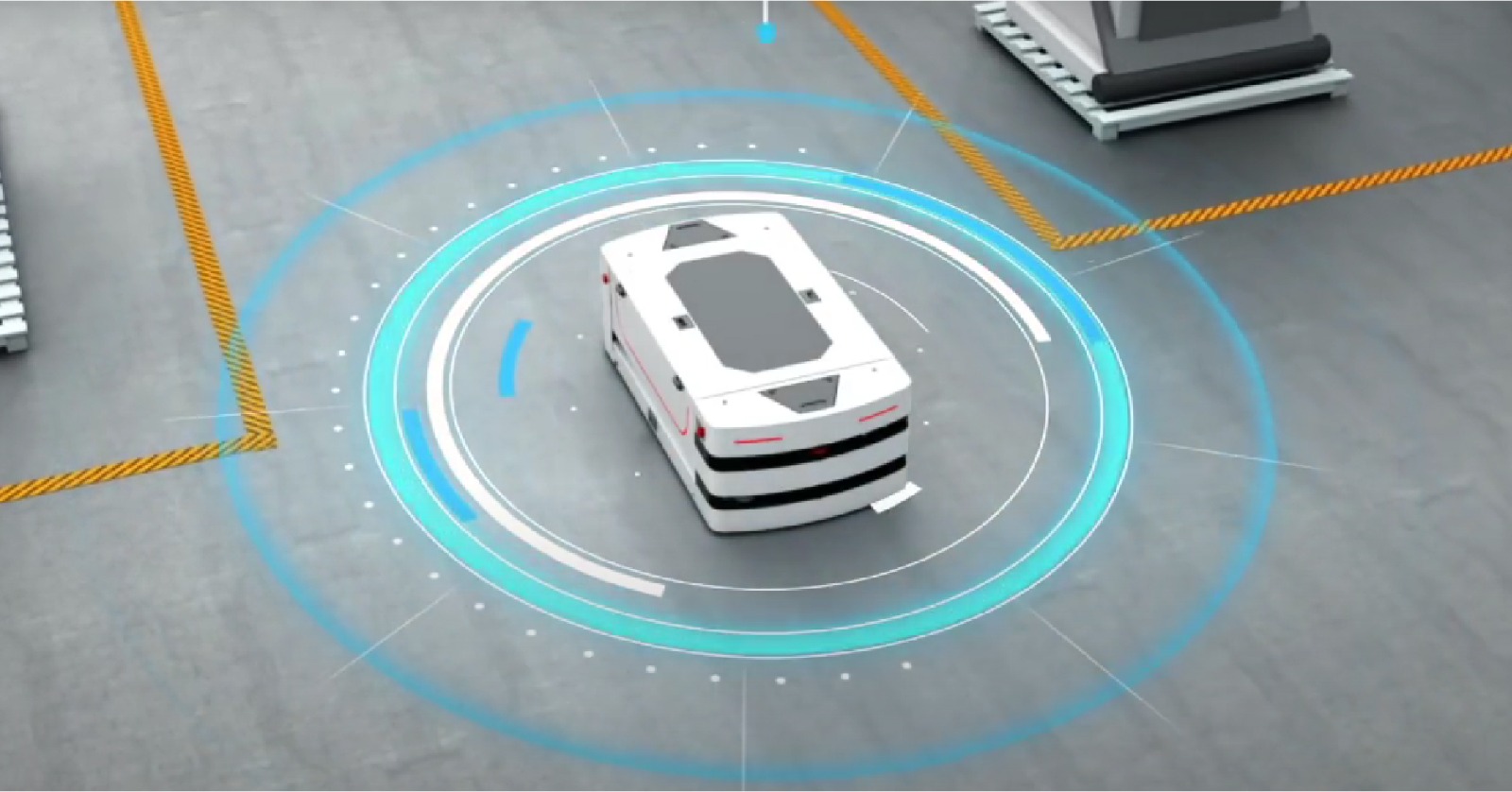

4. Engineered Solutions for Automated Systems

These are advanced automated systems designed for efficient material handling.

Examples include:

- Automated Storage and Retrieval Systems (AS/RS): For automatically placing and retrieving loads from set storage locations.

- Robotic Delivery Systems: Program a robot to do a specific job.

- Conveyor Systems with Integrated Controls: For moving materials in synchronism.

Benefits:

- Increases throughput.

- Reduces errors.

- Increases safety, as less man exposure to heavy machinery.

Novus Hi-Tech, One Stop Solution for all your Material Handling Needs!

Novus Hi-Tech understands the complexities of material handling and provides innovative solutions towards your needs. Material handling equipment we provide to optimize efficiency, safety, and profitability.

- Customized Solution: We measure up your operational needs and provide our bespoke equipment configuration.

- Advanced Technology: Integration of automation and control systems for optimum operation.

- International Presence: With our worldwide leadership in material handling equipment, you may count on continuity and dependability wherever your operations may be.

- Substantial Experience: Decades of experience in terms of meeting the highest standards of material handling solutions.

- Service Support: Extended after-sales support and maintenance.

- Innovation: We continually focus on research and development to bring you or cater you with the best/newest technology.

Conclusion

Material handling equipment is essential for any organization that focuses on increased efficiency, safety and productivity. Getting to know your types of equipment and its benefits will help you in decision-making with regard to your operational goals.

At Novus-Hitech, We aim to provide the world with the best material handling solutions that will make their business grow and reach the heights. Contact us today, to find how we can meet your material handling needs.

FAQs

- Are there 4 types of material handling equipment used in the industry?

Yes, the four primary types of material handling equipment are Storage and Handling Equipment, Bulk Material Handling Equipment, Industrial Trucks and Vehicles, and Engineered Systems for Automated Solutions.

- What is the basic material handling?

Basic material handling involves the movement, protection, storage, and control of materials and products throughout manufacturing, warehousing, distribution, consumption, and disposal processes.

- Why is material handling equipment important?

Material handling equipment is crucial because it enhances operational efficiency, reduces the risk of workplace injuries, minimizes product damage, and improves overall productivity.

- What is material handling equipment in operations management?

In operations management, material handling equipment refers to the tools and systems used to move, store, control, and protect materials, goods, and products throughout the manufacturing, distribution, and disposal processes.