Think back to the factory floor in the late 1980s. Workers would lean over assembly lines utilizing hand tools all day to weld, screw, and package products. Now flash forward to today and that same floor is being utilized with a different rhythm – a smooth robotic arm with precision where several workers once stood. This momentum toward robotics and automation is not accidental. Robotic arms and types of robotic arms have become the backbone of automation and have changed industries like manufacturing, logistics, and healthcare.

However, a word of caution, not every robotic arm is the same. When deciding to select a robotic arm for a task, it can mean the difference between a production cost saving, and an excess cost. That’s why Novus Hi-Tech helps companies successfully identify and deploy robotic arms to build factories that are ready for the future.

Understanding Robotic Arms

At their most basic level, types of robotic arms are programmable mechanical devices meant to mimic the motion of a human arm. Robotic arms include joints, actuators, and controllers that allow them to perform actions with speed, precision, and repeatability. Whether they are picking up a delicate item in logistics, assembling microchips, or assisting in delicate surgical procedures, robotic arms can complete complicated tasks more quickly and safely.

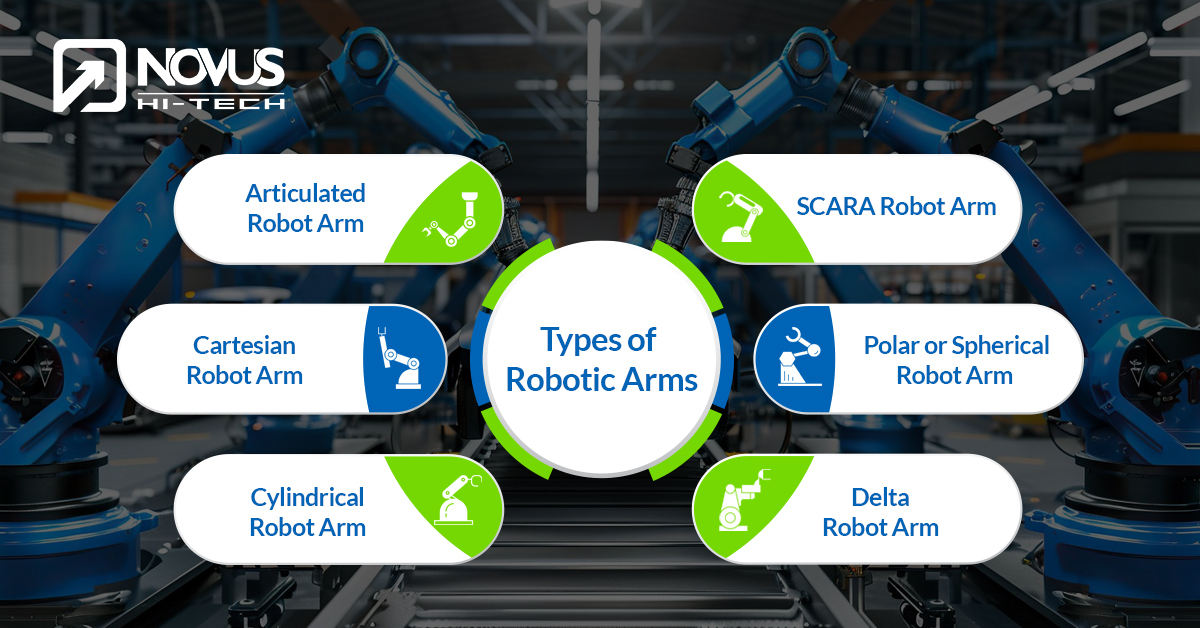

The proper robotic arm is determined by how it moves, what it carries, and where it operates. To understand that, let’s look specifically at the six types of robotic arms that will shape the future of manufacturing.

Types of Robotic Arms

1. Articulated Robot Arm

This robot is like a gymnastic champion. With many joints, the articulated arm is capable of amazing flexibility. It is able to bend, twist and rotate functionally just like a human arm. This is the right arm for jobs that involve welding, painting or complicated assembly. If your operation requires flexibility or a variety of motions, the articulated arm is a fit.

2. Cartesian Robot Arm

If you can draw a cube in 3D, this is why the Cartesian arm exists. The Cartesian arm operates along the X, Y, and Z axes. It is set up to make precision and accuracy attainable. The Cartesian arm is used in CNC machining, pick-and-place, and 3D printing, among many other applications. If spatial measurements or straight-line control is the requirement, Cartesian arms take care of it.

3. Cylindrical Robot Arm

The cylindrical arm can produce combination movement, both rotation and linear, therefore, it is most effective in cramped quarters or vertical space. Factories are often designed around cylindrical arms, to lift materials and load machines, where automation is required in a compact application.

4. Delta Robot Arm

Delta arms are very fast. Delta arms are light weight and mounted overhead, and fly around the room all while working at a maximum speed. You will find delta arms in places like food processing, or electronic assembly; where they would be used for packaging, sorting, and assembly where time is very valuable.

5. Polar or Spherical Robot Arm

This arm imitates the movement of a globe within a spherical range of motion. Its great reach is beneficial for machine tending, die casting, or spot welding operations. Spherical arms excel when an operation calls for movement in a large radius.

6. SCARA Robot Arm

The Selective Compliance Assembly Robot Arm—known as SCARA—excels at horizontal positioning with speed and precision. SCARA arms are often utilized for screw driving, assembly, and pick-and-place systems used in the electronics production process. By blending speed with precision, SCARA arms become essential for high volume production.

Discover how various Robotic Arms shape the future of manufacturing.

Download our free brochure for expert insights and trends!

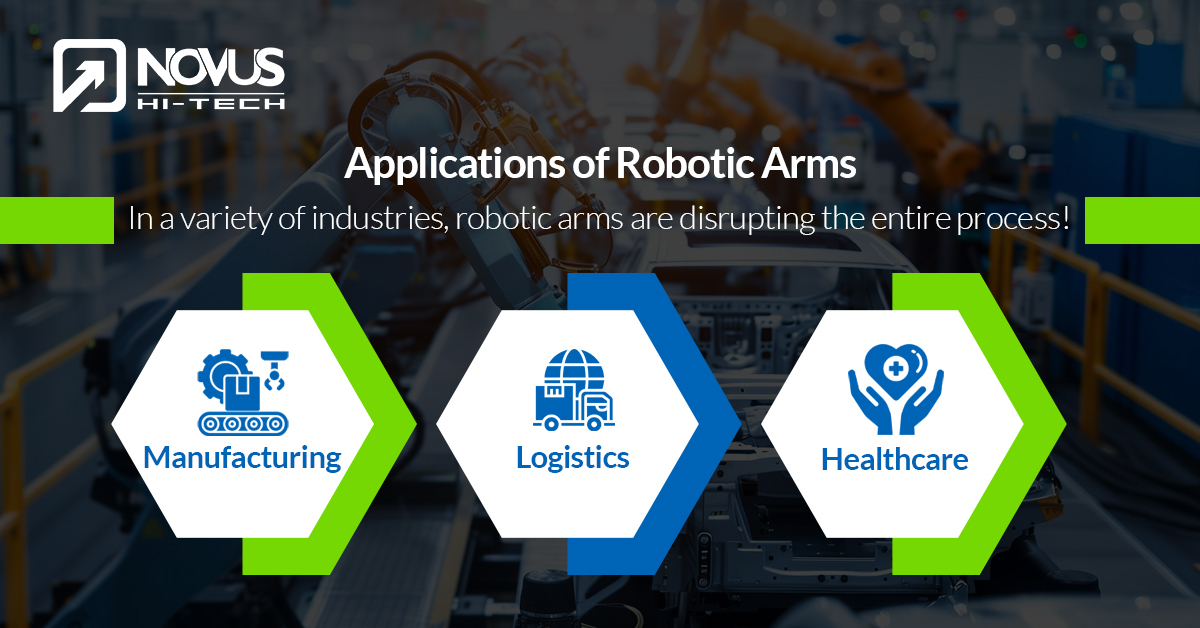

Applications of Robotic Arms

In a variety of industries, different types of robotic arms are overpowering the entire process!

- Manufacturing: Assembly lines are swift and accurate, producing everything from cars to consumer electronics, with an extremely small margin of error.

- Logistics: Robotic arms are picking and sorting material and moving products in warehouses, keeping pace with the growth of e-commerce.

- Healthcare: Robotic arms are enhancing precision for a variety of purposes ranging from assisting surgeons in the operating room to packaging pharmaceuticals.

The magical thing about different types of robotic arms is that each provides a utility where human labor had trouble delivering movement of production.

When to Use Specific Robotic Arms

Selecting a particular type of robotic arm is not merely a technological decision; it involves understanding how to match the arm’s strengths to the requirements of a task. For example:

In need of rapid packaging speeds? A Delta arm is the solution to consider.

Faced with an awkward space constraint? A cylindrical robotic arm will fit the bill.

Eager to complete tasks that require complex, flexible movement? An articulated arm will be the best solution available.

Searching for precision at a low cost? Cartesian or SCARA arms will be a solution in mind.

In some situations, a collaborative robot, or “cobot,” will provide you with the convenience of working beside a human worker, providing an advantage in an environment where flexibility and safety need to come together.

Why Choose Novus Hi-Tech for Robotic Arm Solutions

Although there are several options in today’s market, determining the appropriate robotic arm for the right application will require some expertise. That’s where Novus Hi-Tech comes in. A supplier of articulated, SCARA and collaborative robotic arms, Novus will ensure that businesses don’t just automate their operations, they will enable them to transform their operations into something that is more sustainable for the long-term.

What differentiates Novus Hi-Tech from the others is their commitment to:

- Precision engineered for reliability and accuracy.

- Designs built to withstand use in an industrial environment.

- Integration with your current workflows and systems.

- Delivering turnkey solutions with precision, reliability, and expertise.

Whether your goal is to increase production, decrease costs or increase safety,

Novus Hi-Tech can provide a range of robotic arm options that best fit your needs.

Conclusion

Automation is an ever-evolving story with robotic arms as its main actors. By getting to know the kinds of robotic arms and their various capabilities, all industries can make better choices, maximize their productivity, and safeguard the future of their operations.

Novus Hi-Tech defines the future of manufacturing far beyond machines; it is towards building intelligent operations where every arm becomes a value-added asset.