Introducing Robots

The business world is changing at an unprecedented rate. From shop floors seeing sparks flying in automobile assembly plants to farm fields with sun-swept crops being sprayed or harvested, to sterile hospital rooms where accuracy, margin for error, seconds, are paramount; robots are becoming indispensable. They are no longer “machines” but rather co-workers, aides, and problem-solvers that are disrupting whole industries.

Currently robots’ use across the spatial dimensions (land, sea, air) is no longer limited to automation. They are used to improve human safety, increase productivity, decrease costs, accelerate innovation, and even use higher cognitive functions – none of which were possible less than a decade ago. The epicenter of this transformation is Novus Hi-Tech, a leader in delivering advanced robotic solutions that adapts to an ever-changing industrial context.

But how did we get there? And what is it that makes robots so vital across all industries?

Understanding Robotics in Industry

Robotics in industry can be defined as automated systems that perform either repetitive, difficult, or dangerous work. In contrast to machines, however, robots are intelligent, programmed to behave in ways that are adaptive or able to modify their actions/behavior based on conditions.

In manufacturing, robots can weld to the point of being precise down to a single micrometer. In logistics, robots can navigate a system of crowded warehouses. In health care, robots assist human surgeons to save their patients’ lives. The end result is greater consistency, less error, and even safer workplaces. For business owners who are balancing rising costs against a demand for efficiency, robotics has crossed the threshold of luxury for many and has become a necessity.

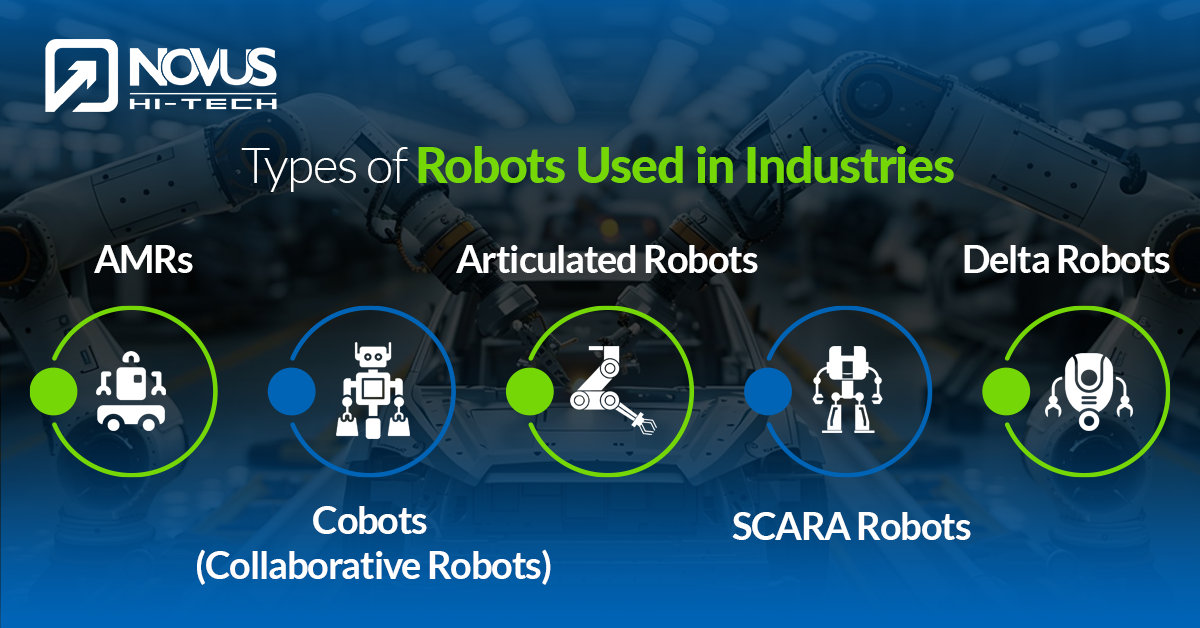

Types of Robots Used in Industries

There are a lot of different kinds of industrial robotics, all suited to specific jobs:

- AMRs: Mobile robots that are sensor-based, not specifically fixed-path, and move product around the shop floor or warehouse.

- Cobots (Collaborative Robots): Lightweight, safe robots intended to work alongside humans – great for small & medium manufacturers and consumer goods companies.

- Articulated Robots: Most people know what these are, right! Human-like arms used for welding, painting or assembling with a level of accuracy unparalleled.

- SCARA Robots: Ideal for picking applications or electronic assembly.

- Delta Robots: Speedy, lightweight robots used in packaging and electronics.

As a whole, these systems show the diversity of uses for robots across various applications ranging from the delicateness of handling materials to heavy lifting.

Discover how robots are evolving in various fields to drive innovation.

Download our free brochure for expert insights and trends!

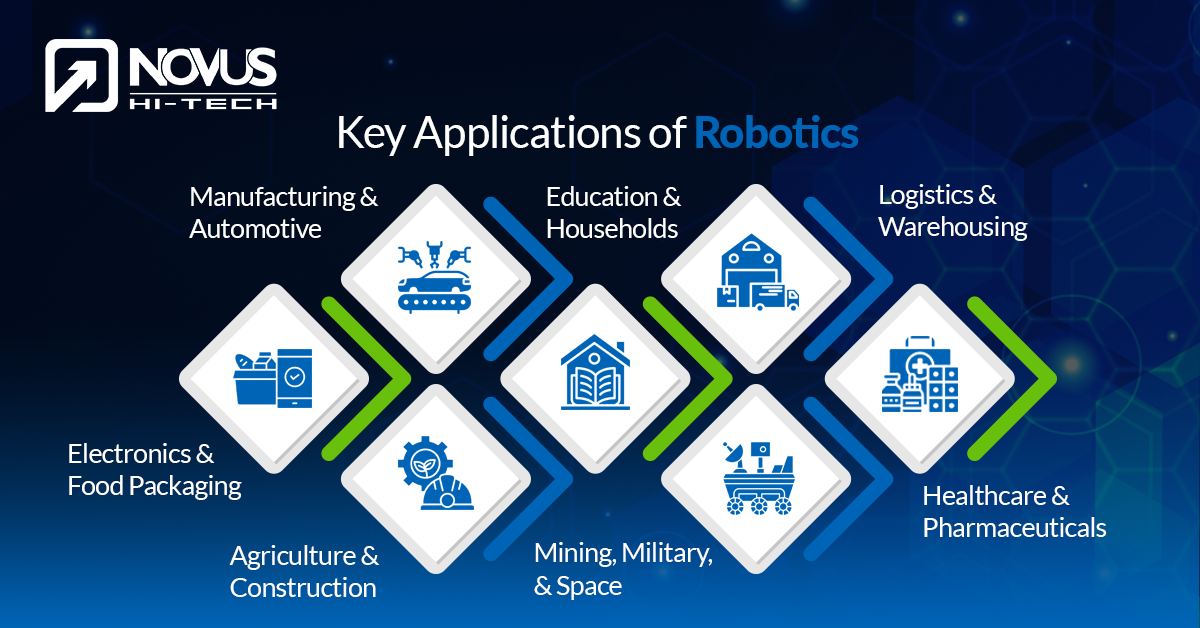

Key Applications of Robotics

- Manufacturing and Automotive

The archetypal use — robotics that weld car bodies, assemble complexity and hoist heavy stuff. They also generate product quality and minimize down time, allowing manufacturers to quickly respond to the worldwide market.

- Logistics and Warehousing

The impact of e-commerce and globalization has fueled warehouses to operationalize shipping for orders more efficiently than ever before. Mobile autonomous robots (AMRs) and robotic palletizers can optimize the tasks of picking, sorting, and transporting, while lowering the repetitive burden on manual labor employees and improving order delivery timelines.

- Agriculture and Construction

Agricultural operations now require more than plows and tractors. New robotic technologies can now drive harvesting and planting, soil monitoring, and even help with irrigation optimization. As well, construction companies now utilize robotic bricklayers and robots and drones for surveying to increase efficiency when operating in construction’s high-risk environment.

- Healthcare and Pharmaceuticals

In healthcare, robotic technologies can assist with navigation and accuracy that exceeds anything a surgeon could recreate. Likewise, robotics play a role even in pharmaceutical laboratories through automation of repetitive pipetting processes and, very importantly, ensuring sterilized handling, which is crucial in all activities related to drug supply to global pharmaceutical supply chains for scientific processes throughout the world.

- Electronics and Food Packaging

Robotics can also be found in electronics and food packaging processes. For example, robotics can be used in new products, such as manufacturing smartphone assembly, applying soldering for dispensing minuscule components and parts, and, finally, food packaging which is typically performed in hygienic rooms, keeping cleanliness and consistency of operations paramount throughout all operations regardless of speed.

- Mining, Military, and Space

Robots continue to offer multiple uses where humans cannot operate. From deep mining shafts to surveillance for military operations, and planetary exploration operations; the role of robotic capabilities is increasing in the most hazardous environments to humans at work.

- Education and Households

And robotics are not only relegated to industrial or specific uses; there are uses for students in the classroom and in-house commercial cleaning robots. Therefore, it is apparent that the use of robotics in multiple sectors have grown from what appeared to be a niche to an everyday occurrence in all sectors of modern life.

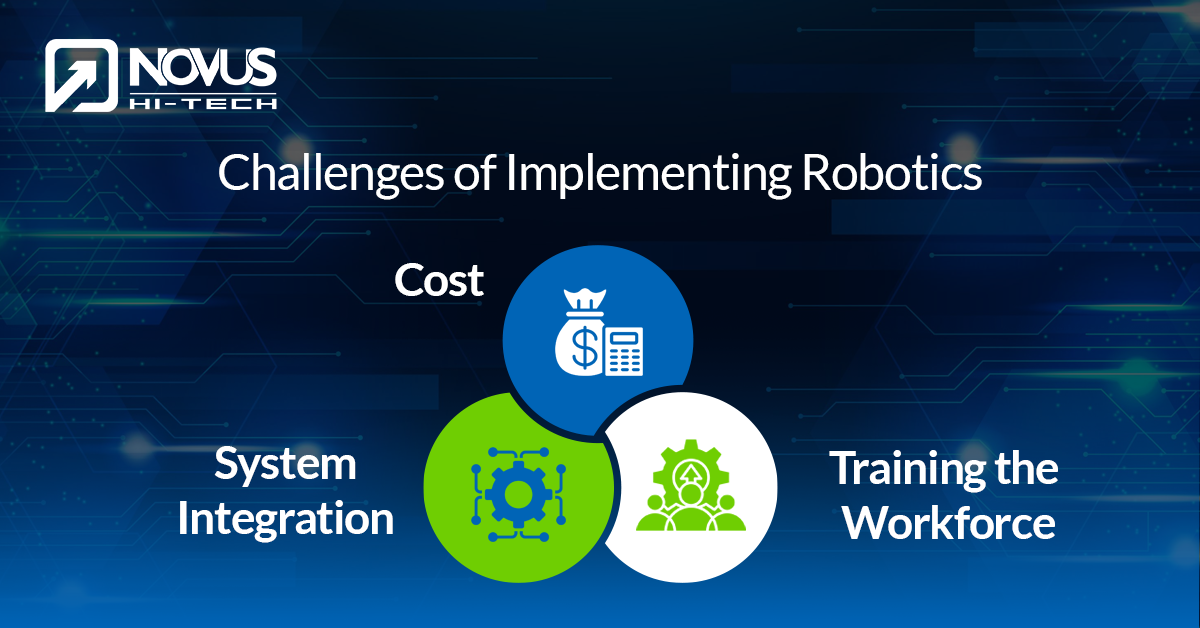

Challenges of Implementing Robotics

Of course, there are challenges when it comes to adopting robots.

- Cost: The initial cost of robots (and the integration of robots and their training) can be high, but as companies see the results in efficiencies, labor safety, and reduced downtime, they recognise the long-term ROI validity of their up-front costs.

- System Integration: Integrating robots with the legacy systems, with non-compatible software/systems can be a more difficult task than with new, ubiquitous software compatibility. However, by taking this into consideration, robust, scaled, and modular systems can be engaged, and this challenge be addressed.

- Training the Workforce: robots are not too different from employees – without skilled operators engaged in ongoing training, success will be limited. Training your employees will not only result in safer patterns of collaboration, but in a greater capacity of productivity.

Companies who meet challenges with robots strategically find themselves at the front of competitiveness and efficiency.

Why Choose Novus Hi-Tech for Robotic Solutions

This is where Novus Hi-Tech makes the difference.

- Wide Application: Novus solutions suit all industries, including manufacturing, logistics and healthcare with AMR, cobots or articulated robots.

- Customization: No two factories or supply chains are identical. Novus’s solutions are designed to fit seamlessly into workflow.

- High Quality: Their systems carry both international certification of compliance and safety, guaranteeing your system is safe to use in mission-critical applications.

- Expert Support: In addition to technology, Novus delivers a continuous training and service support platform that enables robotics deployment with ease.

With Novus Hi-Tech, the challenge of robotics adoption transforms into an opportunity for innovation and leadership.

Conclusion

The application of robotics in various sectors has become a contemporary competitive reality, which used to be portrayed as far-fetched futuristic ideas. Robotics is now a competitive reality in many applications, which was once only a dream of the future. Robots today are part and parcel of industries that manufacture cars, surgeries, crop harvesting, or even Mars explorations. If your company is considering improvements in sectors of safety, efficiency, or innovation, then the question will not remain whether to adopt robotics but the manner and time of adoption. With Novus Hi-Tech, you shall know the path to take-for smarter automation, to grow faster, and to better position yourself for what to come.

👉 Looking to learn more about the ways in which Novus Hi-Tech can optimize your business? Speak with an expert today and give your first step toward smarter automation!