Introduction

If you speak to operations heads today—across warehousing, manufacturing, or even healthcare, you’ll notice a common thread in every conversation: movement. Not high-level strategy decks, not complex dashboards, not even digital twins. It all comes down to movement. How quickly materials travel from one point to another. How safely they navigate busy, high-risk environments. And most importantly, how predictably they move without delays, disruptions, or costly errors. In the end, operational excellence isn’t just about systems or insights, it’s about ensuring that movement on the ground is seamless, controlled, and consistent.

And that’s where Autonomous mobile robots (AMRs) have quietly stepped in.

They’re not flashy machines doing dramatic robotic arms in the air. They generally navigate the interior of a facility by rolling across the ground as they move their supply, pallet, and bin inventory. The main difference between this type of mobility versus traditional methods is that there are no tracks, guide wires or operator control for maneuvering these vehicles. They read their surroundings. They adjust. They choose the best path forward.

That ability to operate inside real, messy, human environments is exactly why AMR applications are spreading across industries. Companies aren’t investing in them because they’re trendy. They’re investing because fixed systems can’t keep up with changing layouts, fluctuating demand, and labor shortages.

Autonomous mobile robot applications are solving a very practical problem: how do you keep materials flowing without constantly redesigning your facility?

What Are Autonomous Mobile Robots (AMRs)?

Let’s remove the marketing gloss for a second.

Autonomous mobile robots (AMRs) are self-navigating transport systems designed to move materials without relying on fixed paths.

But what makes them valuable isn’t just autonomy — it’s adaptability.

They build digital maps of the space they operate in. They detect obstacles. They slow down when someone crosses their path. If a route is blocked, they don’t freeze. They reroute.

In short, they behave more like experienced floor operators than rigid machines.

How AMRs differ from traditional mobile robots

Traditional mobile robots were predictable — but only in predictable environments. They followed predefined tracks. If something changed, operations paused until the route was restored.

AMRs changed that equation.

Because they operate on software-defined mapping instead of physical guides, layout adjustments don’t mean tearing up the floor. A rack can move. A line can expand. The system updates digitally.

That flexibility is what makes modern AMR applications suitable for facilities that evolve every quarter — sometimes every month.

Core technologies powering AMR applications

Behind the smooth movement is a combination of practical engineering:

- AI-driven navigation systems

- Laser and vision-based sensing

- Continuous obstacle detection

- Fleet coordination software

- Integration with warehouse and manufacturing platforms

What matters most isn’t the tech list — it’s the outcome. Autonomous mobile robot applications function safely around people while staying aligned with operational priorities.

AMR Applications in Warehousing and Logistics

Warehouses were early adopters of Autonomous mobile robots (AMRs) for a simple reason: labor-intensive internal transport eats time.

Autonomous mobile robot applications in picking

Anyone who has observed a picking shift knows how much walking is involved. Workers can cover kilometers in a single day.

AMR applications reduce that unnecessary movement. In many facilities, robots now bring shelves or totes to stationary workers. In others, they guide pickers along the shortest path possible.

It sounds simple, but the impact compounds quickly — reduced fatigue, fewer errors, steadier productivity. These autonomous mobile robot applications don’t replace workers; they remove the exhausting parts of the job.

AMR applications for pallet transport and sorting

Pallet movement is repetitive and constant. It also introduces safety risks when forklifts share space with pedestrians.

AMR applications automate pallet transport between receiving, storage, and dispatch zones. They communicate with warehouse systems to prioritize urgent shipments and adapt in real time.

In fast-moving logistics operations, flexibility matters more than fixed speed. Mobile robots bring that adaptability without infrastructure overhaul.

Autonomous Mobile Robots (AMRs) in Manufacturing

Manufacturing floors are becoming smarter — but they’re also becoming more complex. More SKUs. Smaller batch sizes. Tighter timelines.

That’s where Autonomous mobile robots (AMRs) fit naturally.

AMR applications in smart factory material flow

In a traditional setup, forklifts operate on routines. Materials arrive based on schedules. But production rarely stays perfectly on schedule.

AMR applications respond dynamically. If a production line increases output, material replenishment adjusts automatically. If a workstation slows down, deliveries shift elsewhere.

This responsiveness supports just-in-time manufacturing without overloading the floor with excess inventory.

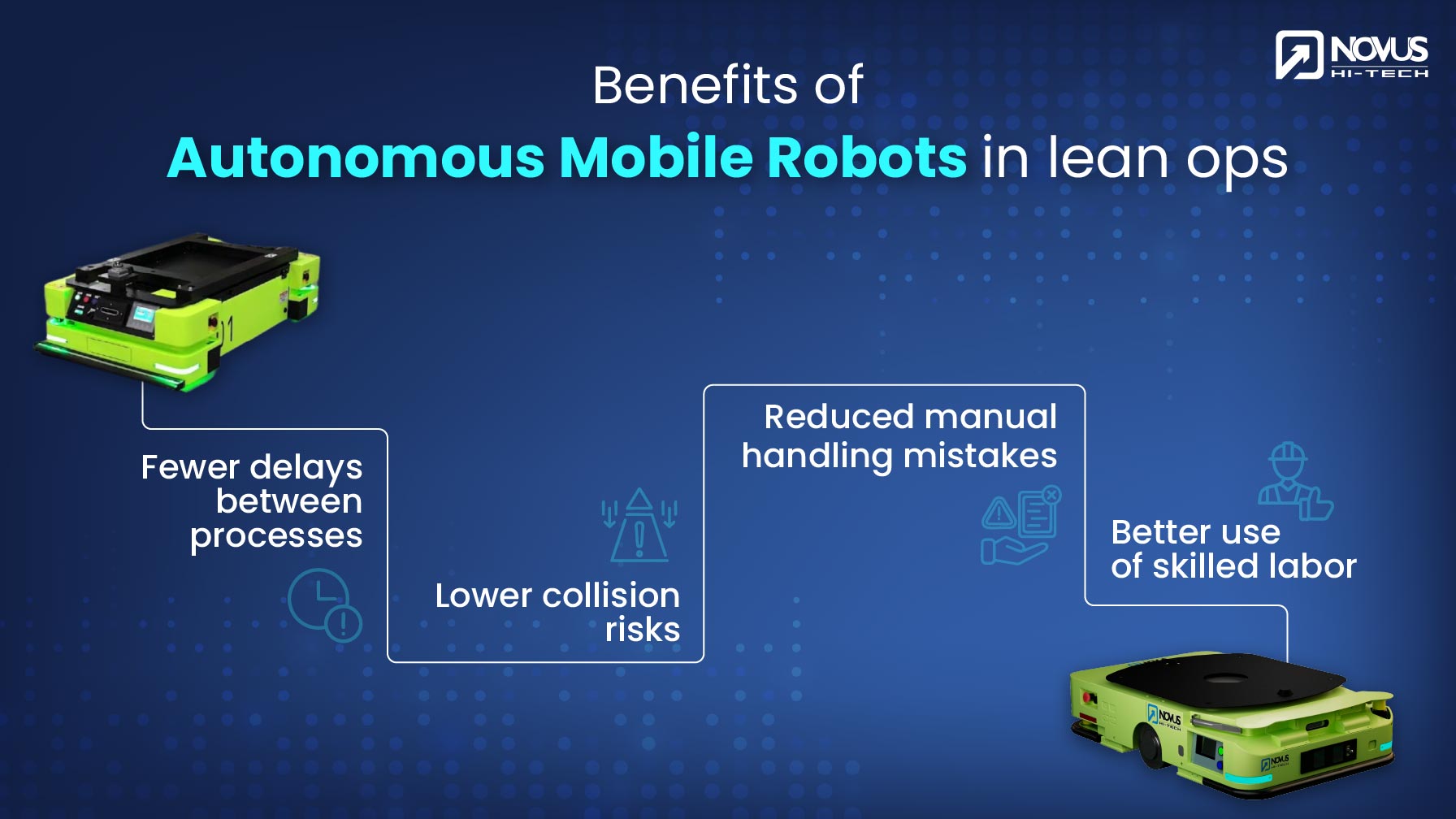

Benefits of autonomous mobile robots in lean ops

Lean operations focus on removing waste — especially wasted movement.

The benefits of autonomous mobile robots in this environment are practical:

- Fewer delays between processes

- Reduced manual handling mistakes

- Lower collision risks

- Better use of skilled labor

Instead of dedicating people to transport, facilities reassign them to tasks requiring human judgment. Over time, that shift improves both efficiency and morale.

Healthcare and Cleanroom AMR Applications

Outside factories, Autonomous mobile robots (AMRs) are solving a different type of challenge: controlled movement in sensitive environments.

Autonomous mobile robot applications in hospitals

Hospitals run continuously, and internal logistics never stop. Medications, test samples, sterile supplies — all must move without delay.

Autonomous mobile robot applications handle these deliveries quietly and consistently. They navigate corridors safely, operate within predefined zones, and reduce unnecessary human contact.

For medical staff, that means fewer interruptions and more focus on patient care.

Mobile robots for sterile and lab environments

In cleanrooms and laboratories, contamination risk is a constant concern.

AMR applications designed for such environments operate within strict hygiene standards while transporting materials precisely. By limiting manual movement, facilities maintain higher sterility levels without sacrificing efficiency.

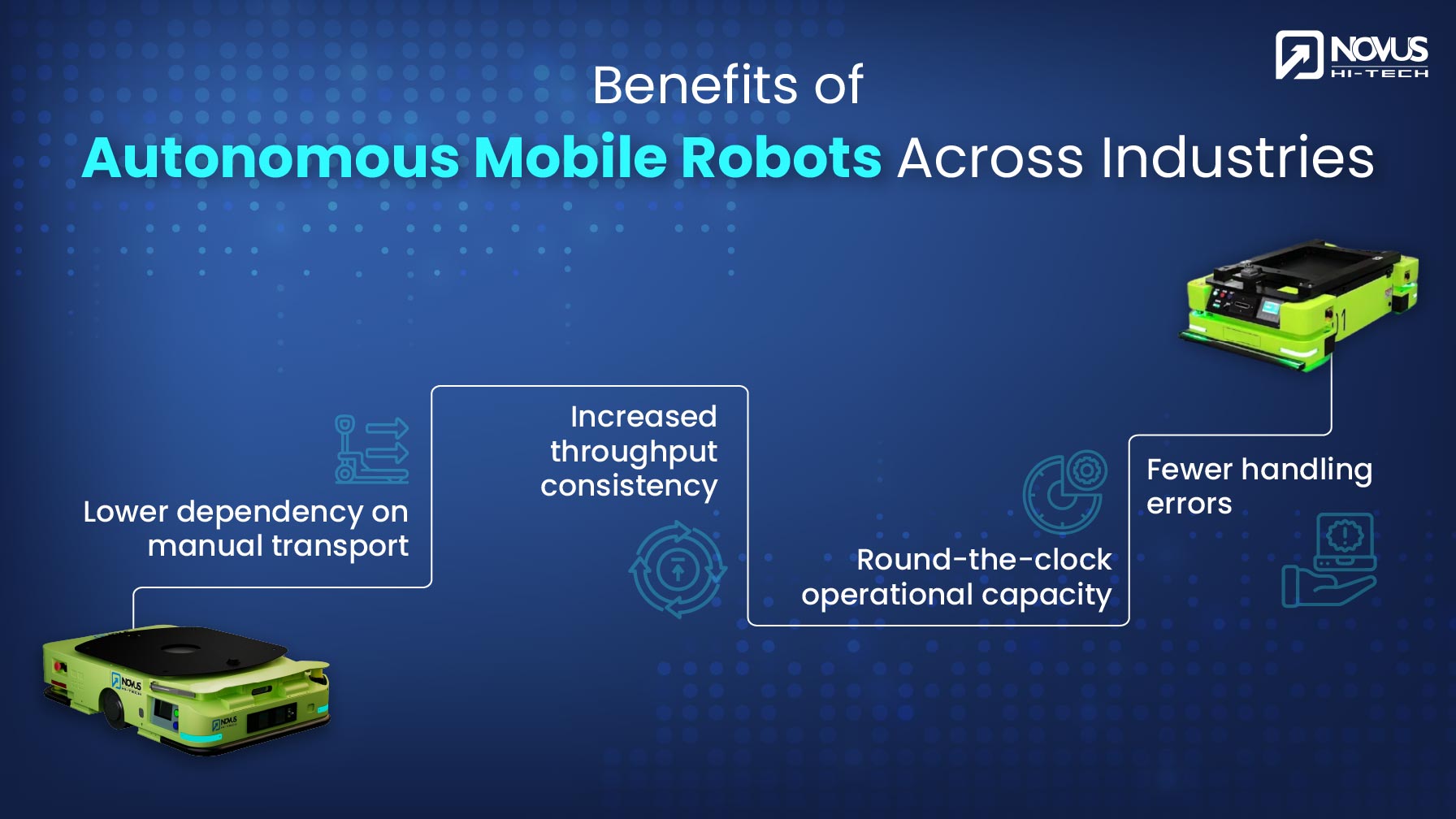

Benefits of Autonomous Mobile Robots Across Industries

The benefits of autonomous mobile robots tend to show up in measurable ways — not just in theory.

Operational ROI from AMR applications

Companies typically notice returns through:

- Lower dependency on manual transport

- Increased throughput consistency

- Fewer handling errors

- Round-the-clock operational capacity

Unlike fixed automation systems, AMR applications don’t demand extensive infrastructure modifications. That reduces both upfront disruption and long-term rigidity.

Scalability and safety with mobile robots

Scaling with mobile robots is straightforward. As volume increases, additional units join the fleet. No major construction required.

Safety also improves. Advanced detection systems ensure robots adjust speed and direction instantly when obstacles appear. That makes autonomous mobile robot applications suitable for shared human-robot environments.

Across industries, these systems aren’t experimental anymore. They’re operational assets.

Conclusion: The Future of Autonomous Mobile Robots with Novus Hi-Tech

Industrial automation is shifting away from static systems toward intelligent mobility.

Autonomous mobile robots (AMRs) represent that shift clearly. They combine flexibility, scalability, and data-driven coordination — all within existing facilities.

As companies modernize factories and intralogistics networks, the focus is no longer just automation. It’s intelligent automation.

Novus Hi-Tech is among the innovators delivering AI-driven AMR applications built for real industrial environments — not just controlled demos. By aligning technology with operational realities, such solutions support safer, smarter, and more adaptable facilities.

The direction forward isn’t rigid automation. It’s a movement that thinks.