In today’s rapidly changing warehouse and factory operations, automation technologies have become essential. Warehouse AMRs (Autonomous Mobile Robots) have emerged as a game changer in material handling, allowing companies to completely rethink their processes.

What Are Autonomous Mobile Robots (AMRs)?

Autonomous Mobile Robots (AMRs) are devices that can navigate on their own to transport materials in unpredictable environments such as factories and warehouses. Unlike traditional Automated Guided Vehicles (AGVs) that have a set path based on fixed paths or systems like QR codes, AMRs are programmed to make real-time decisions based on their surroundings. By using sensors and an algorithm, AMRs can perform a range of tasks as needed, autonomously, with minimal or no input from humans. This allows for flexibility regarding tasks while improving the efficiency of material handling.

How AMRs Operate

The operation of AMRs is powered by cutting-edge technologies:

SLAM (Simultaneous Localization and Mapping):

Allows AMRs to create and update maps of their surroundings, while determining their own location within the map.

Lidar Sensors and Cameras:

Provide real-time information about their environment, allowing AMRs to detect obstacles and navigate their surroundings.

Onboard AI:

Processes the sensor information to make rapid decisions to improve routing and task execution.

Fleet Management System:

Routines AMRs across the entire fleet to assign tasks based on priority, selected by the operator, and availability

WMS Integration:

(Warehouse Management System) WMS makes it easier for AMRs to communicate with their in-process work, helping facility continuity.

In practical applications, AMRs receive commands from a fleet management system when a task is required, following the steps to the target location using information from SLAM and the sensor suite, picking up the material, and delivering that same material to the final drop off location, all while dynamically changing the pre-defined path to improve efficiencies and avoid obstacles.

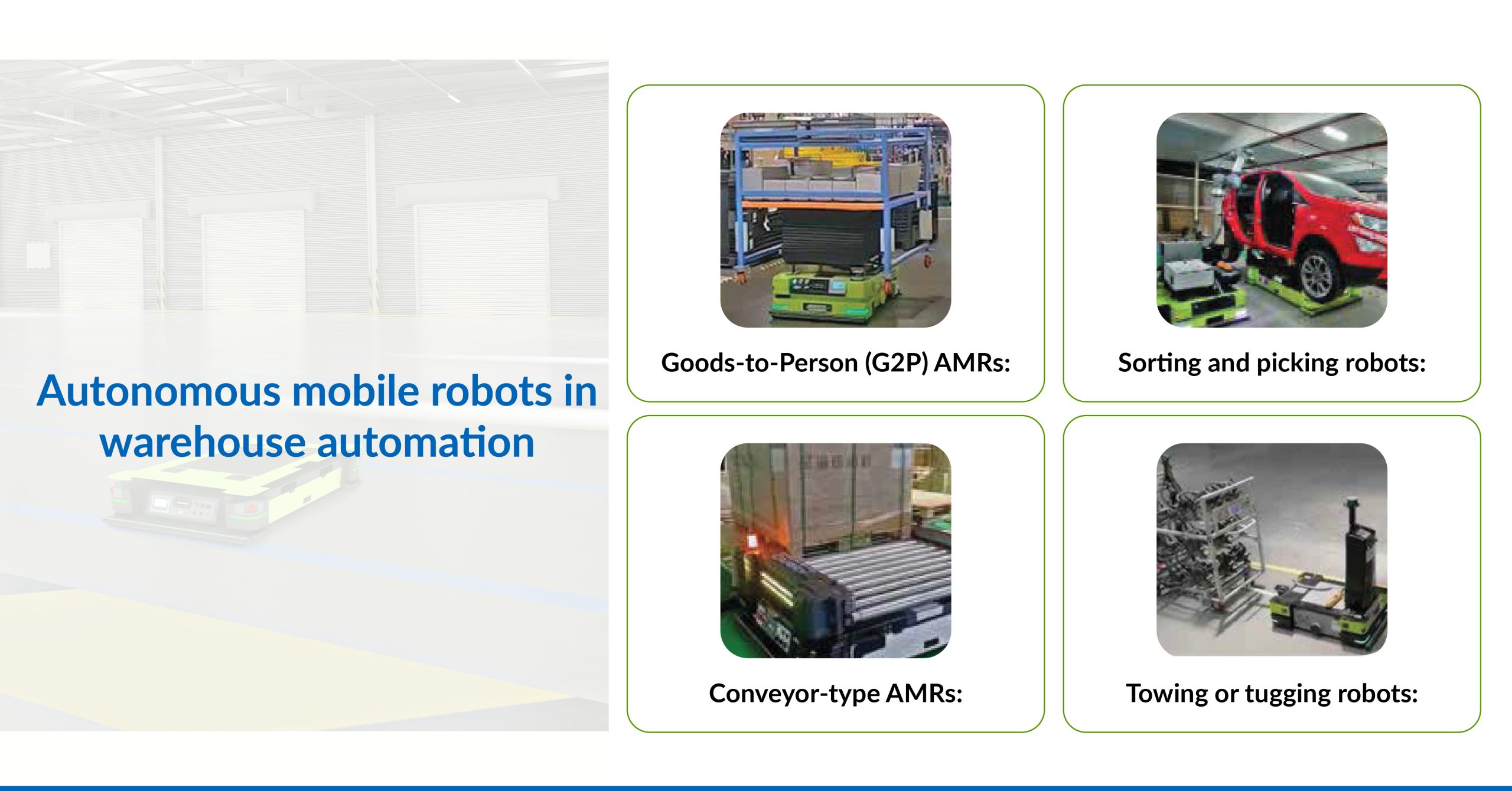

Autonomous mobile robots in warehouse automation

The range of AMRs includes many variations for warehouse automation purposes, including :

Goods-to-Person (G2P) AMRs:

Move goods to human workers rather than requiring the workers to travel throughout the warehouse.

Sorting and picking robots:

The process for organizing and selecting products is automated, therefore order selection of items is faster and errors can be avoided with proper programming.

Conveyor-type AMRs:

Mobile conveyors enable products and goods to keep moving and are able to move continuously throughout the various different areas in a warehouse.

Towing or tugging robots:

Pull carts or trailers loaded with materials, streamlining bulk transportation within facilities.

These warehouse automation robots work in tandem to form a robust, integrated automation system that enhances productivity.

Discover how Material Handling AMRs boost automation efficiency.

Download our free brochure for expert insights and trends!

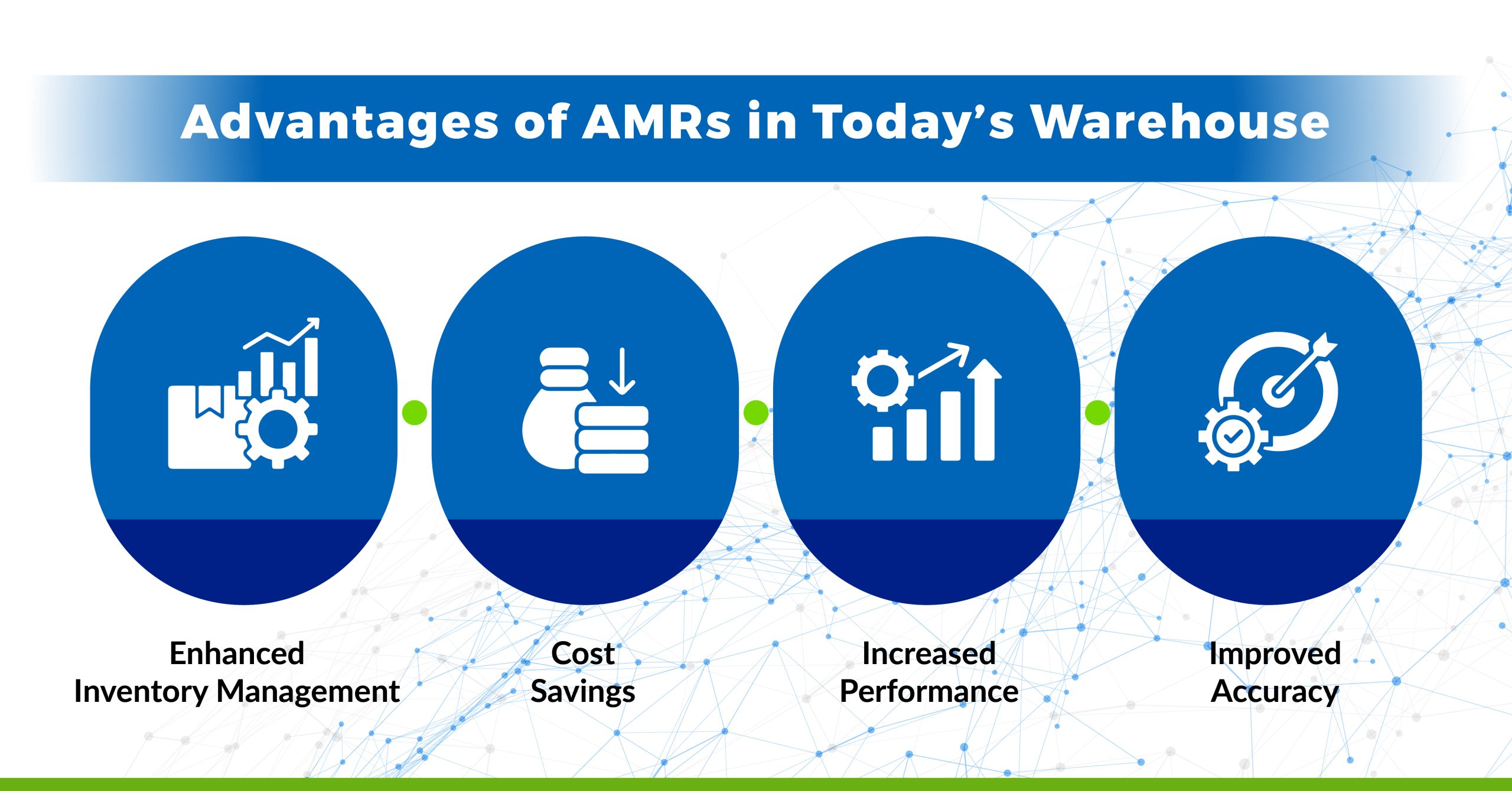

Advantages of AMRs in Today’s Warehouse

Enhanced Inventory Management

Real-Time Data Updating:

AMRs provide real-time status updates on inventory to maintain accurate stock counts.

Automated Replenishment Alerts:

Alerts can be set to notify stock depletion when items drop below threshold amounts.

Reduced Manual Oversight:

AMRs lessen the impact of human error in managing inventory.

Cost Savings

Labor Force Efficiency:

Automate repetitive tasks, allowing human workers to focus on value-added activities.

Reduced Maintenance Costs:

AMRs have reduced fixed and potential maintenance costs compared to conveyor systems.

Increased Performance

Operating Capacity:

AMRs can operate 24/7 and meet the demand in a high-throughput environment.

Modular Scalability:

AMRs can allow the operator to easily add units during peak seasons or expand the fleet of mobile bots with business increases.

Improved Accuracy

More Accurate Order Fulfillment:

Ensure precise delivery of items, enhancing customer satisfaction.

Error Reduction:

AMRs will reduce picking errors by automating all pick and pack processes.

Real-World Impact: Case Studies

Novus Hi-Tech has deployed AMR solutions in multiple industries resulting in realizable benefits:

E-commerce Fulfillment Centre:

By deploying warehouse AMR solutions like Novus CARRY, a leading e-commerce company improved order processing by 30% and cut labor costs by 25%.

Automotive Manufacturing Plant: By putting Novus P-MOVER robots into operation, it was able to better move heavy components, reduce material handling time by 40% and improve worker safety with lesser manual handling.

The evidence reflects the real potential for AMRs to improve operations and promote business growth.

Challenges to AMR Incorporation and Solutions

While the ROI is substantial, there can be barriers to incorporating AMRs:

High Capital Cost:

The initial spend may be significant, though the anticipated savings from labor and efficiency savings will be factored into the cost.

Compatibility with IT systems:

The operational effectiveness requires seamless use of systems, like WMS or ERP. Working with an experience provider like Novus Hi-Tech can meet this necessity with minimal disruption.

Change Management:

Employees may resist new technology. Training and communication can assist in the transition and acceptance.

Facility Layout:

Your facility may need adjustment to the pathway for an AMR. A full site assessment can help to identify potential barriers and facilitators.

If you can proactively work through these potential barriers, then you can realistically capture the benefits of your AMRs.

How Novus Hi-Tech Powers the Future of Smart Warehousing

Novus Hi-Tech is on the leading edge of warehouse automation, providing customized AMR solutions for clients.

Comprehensive AMR Portfolio:

From the versatile Novus CARRY to the heavy-duty P-MOVER pallet trucks, our autonomous mobile robots warehouse lineup fits a broad scope of material handling and transportation needs.

Flexible Fleet Management:

Advanced software ensures optimal task allocation and real-time monitoring of AMR operations.

Full Spectrum Integration:

All Novus AMRs can easily be integrated with most standard warehouse management systems (WMS) and other enterprise resource planning (ERP) systems ensuring seamless integration of AMRs.

Customized Deployment

We collaborate closely with clients to design and implement solutions tailored to specific operational requirements.

Proven Track Record

With success stories from multiple applications of automation technology within logistics, retail and manufacturing, we have showcased improved operational efficiency.

Novus Carry Autonomous Mobile Robots

Our Autonomous Mobile Robots (AMRs) are designed to improve material handling in warehouses and manufacturing facilities. Our AMRs, such as Novus CARRY and Novus P-MOVER, utilize advanced navigation (Lidar + SLAM), real-time task assignment, and intelligent fleet management offer:

- Payload capacity up to 1500 kg

- 360° obstacle avoidance

- Autonomous charging & minimal installation

- Seamless integration with existing WMS/ERP software

From moving pallets to goods to parts—our AMRs are designed to adapt, scale, and deliver operational efficiencies. Explore our AMR product range here.

Adopting AMRs is a strategic leap toward operational excellence. Autonomous mobile robots warehouse automation empowers businesses to improve productivity, accuracy, and scalability. As warehouse demands evolve, AMR adoption will become key to staying competitive. We are paving the way in manufacturing and warehouse automation. Contact us today to join the revolution.

FAQs

1. Are AMRs safe to use around human workers?

Yes, AMRs utilize sophisticated sensors and safety protocols to ensure safe navigation and interaction within a warehouse environment. As a core part of any warehouse AMR system, these automated robots in warehouse settings are designed to operate safely around human workers, enabling a collaborative and secure workspace.

Yes, AMRs utilize sophisticated sensors and safety protocols to make safe movements in a warehouse/factories with humans, providing a safe work environment.

2. How do Autonomous Mobile Robots navigate inside a warehouse?

AMRs combine mapping technologies such as SLAM, Lidar, and onboard AI. These warehouse automation robots do not require fixed paths, allowing them to move intelligently and adapt in real time, enhancing operational flexibility.

3. Are Autonomous Mobile Robots able to interface with my existing WMS or ERP?

Certainly. Novus Hi-Tech’s warehouse AMRs are built with seamless integration in mind. Our autonomous mobile robots warehouse solutions can interface with most major WMS and ERP platforms, ensuring end-to-end operational connectivity.

4. Do I have to change my warehouse layout greatly to use Autonomous Mobile Robots?

No major changes are required. Most automated robots in warehouse settings, including Novus AMRs, are designed to work with existing layouts. Minimal adjustments can further optimize performance, but the adaptability of our warehouse AMRs ensures smooth deployment without massive infrastructure overhauls.

5. Can Novus Hi-Tech provide custom AMR solutions for specific industries?

Yes. Novus Hi-Tech excels at delivering customized warehouse automation robots tailored to meet the specific needs of industries such as logistics, manufacturing, retail, and more. Our autonomous mobile robots warehouse offerings are built to fit diverse operational demands with precision.