Picture a location such as a warehouse full of action, where forklifts are speeding around moving heavy loads. Forklifts are a great asset in keeping the flow of work, but they can be dangerous if operated improperly. Forklift danger is a cause of thousands of workplace injuries each year. Keep in mind that providing a safer forklift operation is more than a compliance issue, it is ultimately the lives of your people as well as being an invaluable substitute for lost dollars/time and rewards.

So what can organizations do to eliminate the danger and reduce the likelihood of those hazards?

Let’s talk about the standard hazards often present in the use of a forklift and how to practice safer operation of forklifts.

Essential Forklift Safety Risks & Best Prevention Strategies

1. Inadequate Operation & Training

One of the biggest forklift hazards is actually an untrained or improperly trained operator. Forklifts are powerful machines that can be mishandled which can result in tip-overs, collisions, and injuries.

Best Practices:

As aforementioned, make sure operators are properly certified and have refresher training.

- Schedule safety policies that require safe driving and maneuvers

- Additional training programs need to be scheduled for training and simulations.

2. Load Imbalance & Overloading

Improper stacking or overloading of loads can lead to forklift overturning or dropping of materials, resulting in expensive damages and safety hazards.

Best Practices:

- Don’t overload the forklift beyond its rated capacity (refer to the load rating plate).

- Dispose of weight evenly to ensure stability.

- Leave the load low and slightly tilted backward to improve balance.

3. Poor Equipment Maintenance

Abandoned forklifts with worn brake pads, failing hydraulics, or broken steering can become a serious safety risk.

Best Practices:

- Perform daily pre-use checks.

- Schedule regular maintenance and repairs.

- Utilize predictive maintenance technology to identify potential problems before they become major issues.

4. Blind Spots & Limited Visibility

Limited visibility is a common problem for forklift operators, which can result in unintentional collisions, especially in confined areas.

Best Practices:

- Mount mirrors, cameras, and proximity sensors.

- Train operators to utilize spotters when approaching blind corners.

- Utilize AI-based navigation systems for enhanced awareness.

5. Unsafe Floor Conditions

Wet, uneven, or cluttered floors may lead forklifts to skid or overturn, putting operators and pedestrians at risk.

Best Practices:

- Keep floors clean and dry at all times.

- Properly sign high-risk areas.

- Apply anti-slip coatings to warehouse floors for better traction.

6. Pedestrian Safety Risks

Pedestrians walking alongside forklifts are extremely susceptible, especially in busy areas.

Best Practices:

- Create distinct pathways for pedestrians and forklifts.

- Mount barriers and warning lights at intersections.

- Train staff in pedestrian safety when approaching moving forklifts.

7. Overhead Hazards

Low-clearance fixtures like pipes, beams, or lighting may be responsible for forklift mishaps if the operators are not vigilant.

Best Practices:

- Make clearance checks prior to forklift operation in a new area.

- Implement the use of height sensors to inform operators of overhead obstructions.

- Implement slow-speed zones in hazardous overhead areas.

8. Wrong Fueling & Battery Charging

- Handling forklift fuel or batteries incorrectly can lead to fires, toxic exposure, or even explosions.

Best Practices:

- Train operators on proper fueling and charging procedures.

- Set up designated refueling and charging stations away from high-traffic areas.

- Keep fire extinguishers and emergency spill kits accessible.

9. Safety Considerations for Forklift Attachments

- Attachments like clamps, rotators, or platforms can enhance a forklift’s capabilities, but improper use can cause instability and accidents.

Best Practices:

- Provide operators with specific training for every attachment utilized.

- Check attachments for wear and tear prior to utilization.

- Adhere to the manufacturer’s instructions for weight capacity and handling procedures.

Discover how advanced Forklift Operations enhance efficiency and safety.

Download our free brochure for expert insights and trends!

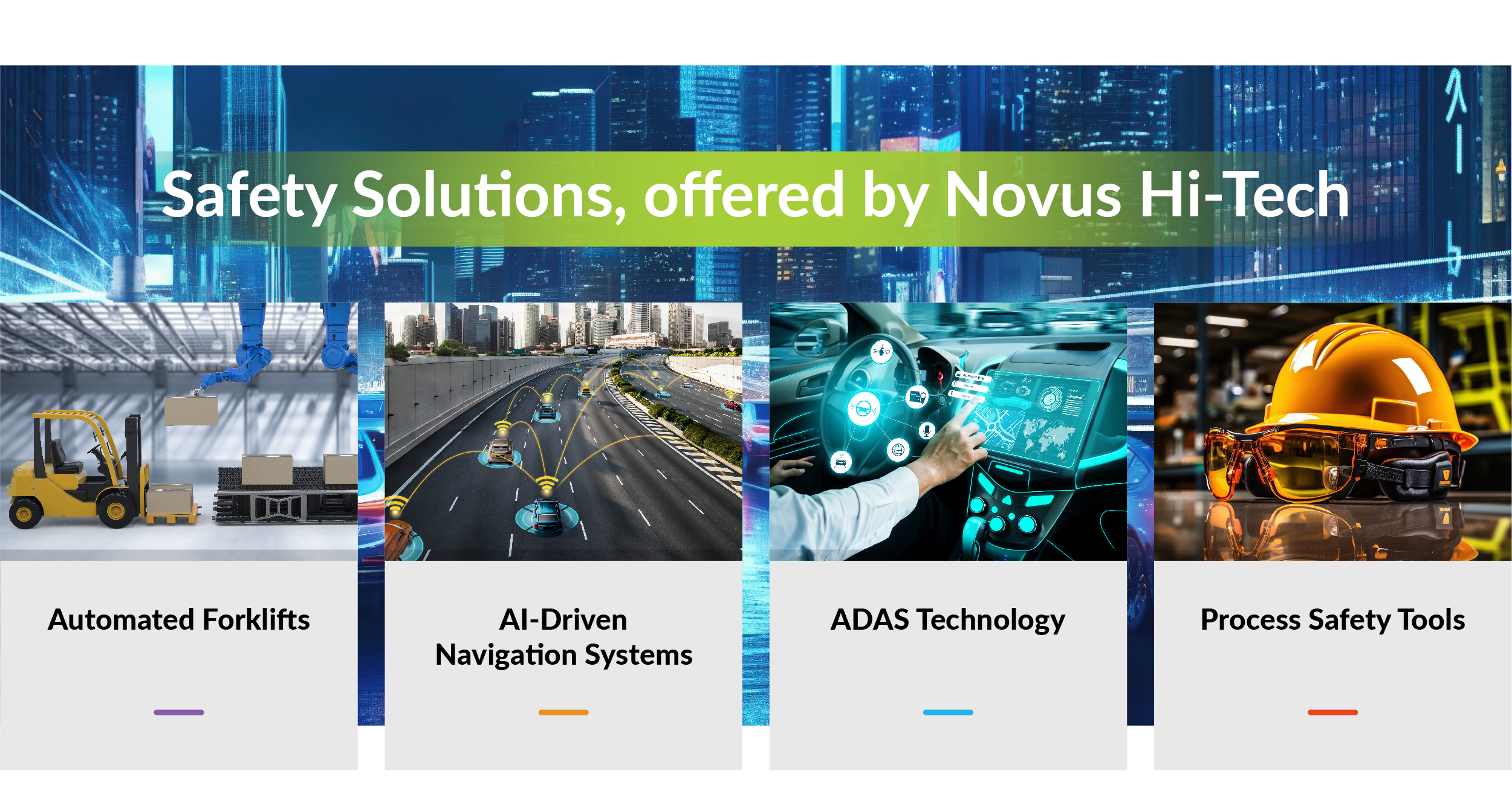

Forklift Safety Solutions, offered by Novus Hi-Tech

Challenges for worker safety and operational hazards related to distinct types of forklift operations require effective solutions. Our services and technologies enhance forklift safety while improving operational efficiencies and reliability.

- Automated Forklifts – By employing automation processes, we minimize the potential for human operational error and improve overall efficiency.

- AI-Driven Navigation Systems – The advanced lenses and AI-assisted algorithms enable real-time assistance for an operator and are designed to prevent accidents that occur in blind spots.

- ADAS Technology – The various uses employed in our provided technologies utilize multiple levels of collision detection systems and lane assist capabilities to mitigate and minimize the risks of crashes.

- Process Safety Tools – Advanced AI-driven solutions for predicting maintenance systems identify key signs and symptoms of early mechanical failure to avoid breakdowns and incidents that could result in accidents.

Businesses can utilize the solution and be able to mitigate forklift safety and hazards through various smart automated solutions.

Conclusion

Forklifts are a necessity in most industrial operations, but safety has to remain a priority. From adequate training and equipment upkeep to taking advantage of cutting-edge technology, companies have several means to reduce forklift risks. Investing in a safety culture does more than avoid accidents by enhancing productivity and operational efficiency.

Want to raise forklift safety at your workplace? Reach out to Novus Hi-Tech today and learn about our cutting-edge forklift safety solutions!

FAQs

1. What are the first rules of a forklift?

Always perform a pre-use inspection, wear proper safety gear, maintain a safe speed, and ensure the load is stable before moving.

2. How to calculate forklift load capacity?

Refer to the forklift’s data plate, which specifies the maximum load capacity based on weight distribution and height.

3. What is the 3-meter rule for forklifts?

Operators should maintain at least 3 meters (10 feet) of distance from other forklifts and pedestrians to prevent collisions.

4. What are the 6 pre-start checks for forklifts?

- Inspect tires and wheels.

- Check brakes and steering.

- Ensure the forks and mast are in good condition.

- Examine fuel or battery levels.

- Test horn, lights, and warning signals.

- Look for any visible leaks or damages.