In today’s fast-paced dynamic industrial world, Manufacturing Industrial Robots (MIR) are at the front foot of reshaping production lines and elevating efficiency. With advancement in technologies and AI integration, robots are becoming a mandate or major addition to industrial manufacturing.

From assembly to material handling, robots are crucial for manufacturing and upscaling industrial growth with lower costs. But what’s next? As we look ahead to the future 2025 and beyond, what trends will continue to shape Industrial robots for manufacturing? Let’s explore this out!

How Are Robotics Transforming Manufacturing and Production?

Robots have revolutionized manufacturing industries, driving significant changes in how industries operate. At present, various robots are used in manufacturing i.e;

- Assembly Lines: Industrial robots handle tasks like assembling small components with speed and precision, reducing human error or accidents.

- Welding and Material Handling: Robots manage repetitive tasks like welding, packaging, and loading heavy materials. They operate with consistency, ensuring better quality and reducing time.

- Precision Machining: Robots perform tasks that require precision that would otherwise be very time-consuming or challenging for human workers.

These transformations highlight how industrial manufacturing robots are generating smarter, more efficient production environments.

Discover how Manufacturing Industrial Robots boost efficiency and innovation.

Download our free brochure for expert insights and trends!

Why Robots Are Taking Over Manual Tasks in the Manufacturing Industry

The transition from manual labor to robotic automation is dynamically expanding due to several various factors:

- Industrial robots in manufacturing offer unmatched efficiency, performing repetitive and dangerous tasks quicker than humans while minimizing the risk of error. In industries like automotive and electronics, robots handle tasks like welding, painting, and assembly with accuracy that improves product quality and consistency.

- The other main driver has to do with safety. The automation process can take place in aggressive environments so that humans are not exposed to such a harsh environment, and thus, human workers cannot perform in risk-prone areas. In addition, by automating routine and mundane tasks of manual labor, companies can redeploy the workforce to higher-value-added complex jobs and thereby increase productivity and quality jobs.

- The most prominent benefit is the savings on cost. While the buying price for industrial robots used in manufacturing is not exactly cheap, the fact that it will eventually pay off fully, with efficiency improvements, less waste, and virtually no downtime, speaks volumes.

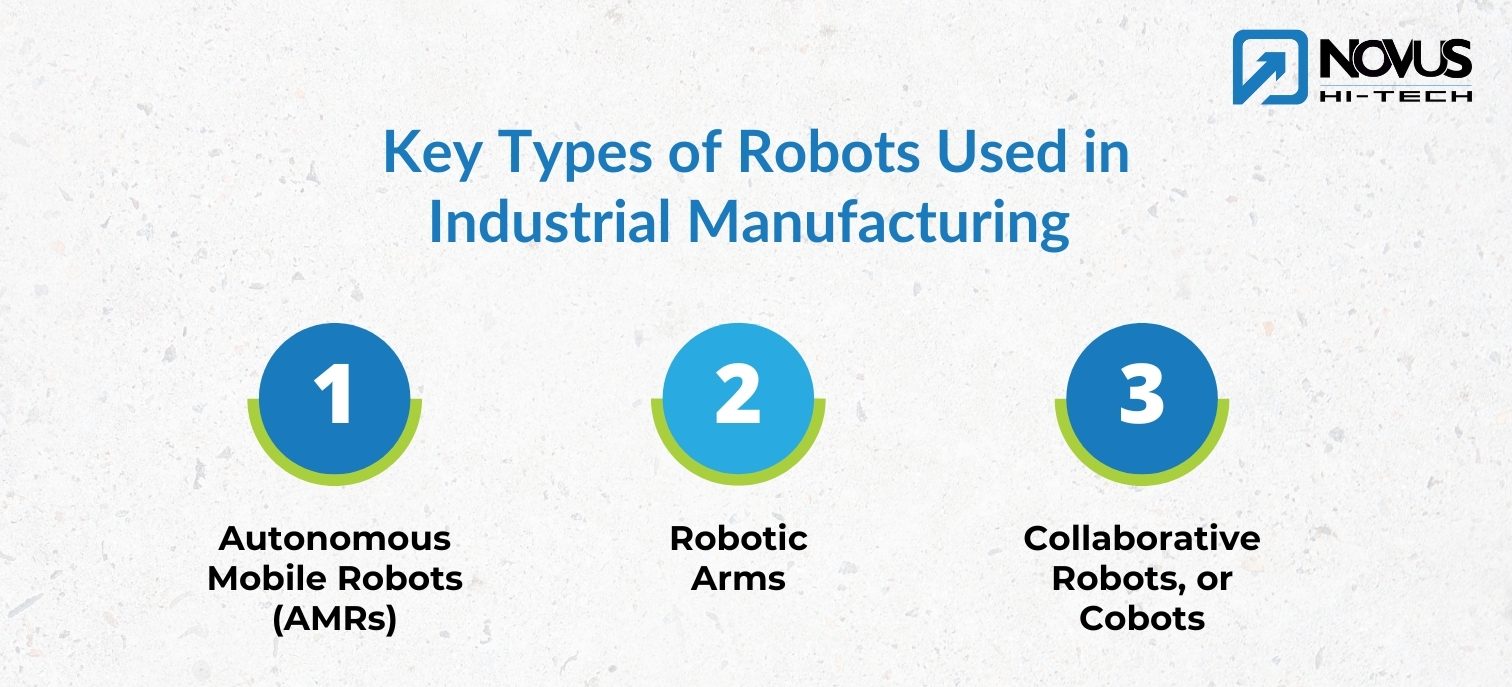

Key Types of Robots Used in Industrial Manufacturing

Since the industry changes daily, various types of robots have been brought up to cater to the different needs for various manufacturing processes. The most frequently used industrial robots in manufacturing include the following:

- Autonomous Mobile Robots (AMRs): AMRs are different from other fixed-position robots because they can drive through a factory floor and also execute logistics processes, such as moving materials or parts.

- Robotic Arms: The robots are very versatile and are mainly applied for welding, painting, and assembly. They offer precision and reliability, especially for repetition work.

- Collaborative Robots, or Cobots: Cobots are designed to work in collaboration with humans. They enhance productivity and safety. They help perform jobs involving human interaction. Such as quality control as well as product testing, the hallmark of this production environment is flexibility within the production environments.

All these autonomous robotic types have some very unique advantages, which manufacturers look forward to solving specific operating problems on the manufacturing floor.

Benefits of Autonomous Mobile Robots in Manufacturing

AMRs are being acknowledged in various industries like manufacturing, automotive, and electronics for their ability to work solely without human intervention. They use AI-driven navigations, advanced sensors, and real-time data processing to optimize day-to-day operations in manufacturing environments.

AMRs can benefit in a number of operations like:

Flexibility: AMRs are programmed to perform multiple tasks, such as transporting material across different areas of the factory floors. This adaptability helps companies manage fluctuating production demands.

Efficiency: AMR reduces downtime and human interference, resulting in higher productivity, workflows, and fewer bottlenecks.

Safety: The AMR is designed to avoid human workers and even other obstacles safely; it allows for fewer chances of accidents on the floors of a factory.

Therefore, the main difference between AMRs and other traditional industrial robots lies in the extra efficiency level in the manufacturing process. Helping companies optimize their performance in operations and reduce costs.

Conclusion

As the calendar advances into 2025 and beyond, industrial robots in manufacturing will continue to find newer trends with advancing AI, machine learning, and sensor technology. Companies that utilize industrial robotics for manufacturing purposes are in for a pretty good change in productive value, safety, and cost savings. Innovations like AMRs, ABOPTs, and Cobots drive them, and so has the future of manufacturing never looked more automated and efficient.

This innovation at Novus Hi-Tech leads the change with cutting-edge AMR solutions and state-of-the-art robotics that refine the way manufacturers operate: smarter, safer, and more efficient production environments. We are dedicated to reshaping the future of industrial automation.

FAQs

- What makes Novus Hi-Tech stand out in the manufacturing robotics industry?

Novus Hi-tech leads the industry with cutting-edge manufacturing industrial robots and tailored AMR solutions that enhance production efficiency.

- What industries benefit the most from using manufacturing industrial robots?

Automotive, electronics, and aerospace industries see the most significant gains from industrial robots in manufacturing, thanks to their need for precision and scalability.

- How do industrial robots improve production efficiency?

Industrial robots automate repetitive tasks, reducing human error, increasing speed, and enhancing the overall quality of the manufacturing process.

- Are manufacturing robots replacing human workers entirely?

No, robots help human labor by automating repetitive or difficult tasks, allowing workers to focus more on other strategic tasks/roles.

- How do collaborative robots (cobots) differ from standard industrial robots in manufacturing?

Cobots are crafted to work alongside humans, providing safety features like force sensing, whereas standard robots operate independently of human interaction.

- What safety measures are in place when using industrial robots?

Safety measures include sensors, emergency stops, and barriers to ensure that robots operate in a controlled environment

- How expensive is it to implement industrial robots in a manufacturing facility?

The cost depends on the type of robot and the customization required. However, the long-term savings from increased efficiency often outweigh the initial costs/investment.

- What are the key trends shaping the future of manufacturing robots in 2025 and beyond?

The integration of AI, machine learning, and autonomous capabilities is driving the next generation of manufacturing industrial robots, making them smarter, more efficient, and more adaptable.

- How are manufacturing robots programmed for specific tasks?

Robots are programmed to use specialized software that allows them to perform specific tasks, such as welding or assembly, with precision and consistency.