Robotics is advancing rapidly, and 2025 is a monumental year for automation, artificial intelligence, and human/robot partnerships. Robotics technology will find applications in the manufacturing floor, hospital room, field, and beyond! Exciting advances in robotics, automation, AI, and other frontiers will change how we do business, create a greater participation in productivity and reliability in human-robot relations. Novus Hi-Tech was an early leader in robotics and automation to help realize the industry’s ability to implement these futuristic opportunities.

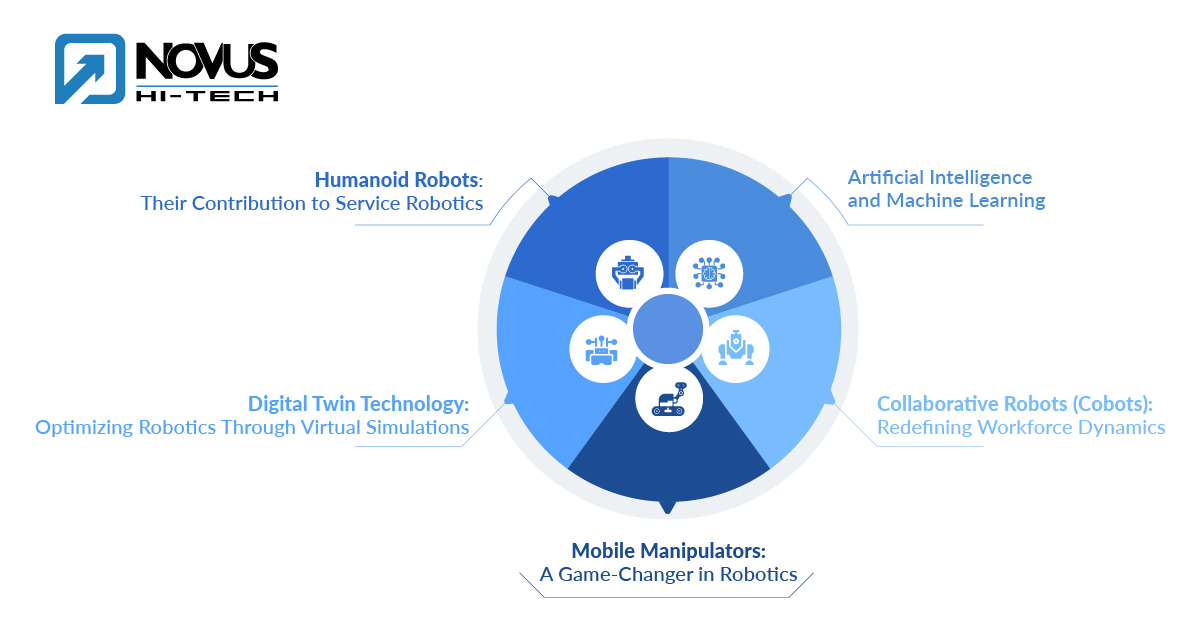

Artificial Intelligence and Machine Learning

Robotics will continue to make the most significant changes in 2025, driven primarily by Artificial Intelligence and Machine Learning developments. In 2025, we will see robots that exploit environmental inputs in multiple situations, self-learn to dynamically adjust to situations, and improve performance quickly without constant human adjustments.

For example, we expect robots to engage in predictive maintenance, autonomous navigation, or precision manufacturing with intelligent robots automatically adjusting with little human interference. Greater use of AI and robots will allow robots to perform with greater speed, safety, and smarter in a range of settings across multiple industries.

Discover how Industrial Robots boost efficiency and innovation.

Download our free brochure for expert insights and trends!

Collaborative Robots (Cobots): Changing Workforce Relationships

Cobots do not require safety cages because they can operate safely next to humans on the work floor. By 2025, cobots will be more responsive, intuitive, and sensor-aware with more advanced AI, making it easier to use cobots to increase throughput on a manufacturing line, as well as perform delicate, quick, collaborative tasks for the healthcare, retail, and logistics industries. Cobots relieve workers from more repetitive and hazardous tasks, contributing to a more comfortable work environment, operating more safely and efficiently.

Mobile Manipulators: The Next Level of Robots

Mobile manipulators are a combination of mobile robots that can navigate and manipulate their environment, and robotic arms that manipulate within a defined work area, which are growing quickly in the field. Mobile manipulators represent a flexible system that can navigate without the restriction of a work area to provide a multitude of tasks such as inventory picking, surgical assistance, or machine tending. Thanks to real-time sensors and AI algorithms, mobile manipulators may adapt to changing variable tasks and provide versatility to environments that change in nature (e.g., various terrains). These are important for robotization in logistics, healthcare, or warehousing operations.

Digital Twin Technology: Improving Robotic Systems with Simulations

Digital twin technology is changing how robots are designed, developed, and deployed in the world. With digital twins, engineers can build virtual representations of physical robotic systems and subsequently, simulate how they would operate, as well as identify inefficiencies in their operations or performance prior to developing a final form. This means lower research and development costs, quicker deployment, and improved reliability. By 2025, the engagement of digital twins mixed with robotics trends will be the way of the future for smart factories and industries that rely heavily upon automation.

Humanoid Robots: A Help for Service Robotics

Humanoid robots, designed to look and engage like humans, are becoming more popular in service environments. As we see an increase in customer service, elder care, and hospitality approaches, these humanoid robots are designed to engage and offer an empathetic approach, whilst being able to understand voice commands, facial expressions, and context. As we continue to see advances in AI, it is safe to assume that humanoid robots will increasingly begin to take on complex tasks in unstructured environments, which will enhance a customer’s experience, as well as reduce dependency on human staff.

Customization and Modularity in Robotics

Key Trends in Robotics Customization

With increasing demand from industry, the one-size-fits-all approach is disappearing. Robotics and automation in manufacturing are shifting towards customization and modularity, where components can be configured for specific use cases. Modular robots can be reprogrammed or reconfigured at will, which minimizes downtime and optimizes your investment through flexibility. Modularity fits well in high-mix, low-volume production environments.

Sustainable Robotics and Energy Efficiency

Another emphasis of robotic advances is sustainability. Robots are being designed to use less power, constructed from recyclable materials, or with lower emissions. Green robotics isn’t just a trend, it is a need for organizations that need to meet environmental compliance and achieve carbon neutrality. Energy-efficient drive motors, better algorithms for optimizing routes, and solar-powered systems will be the most exciting developments to come in 2025.

Novus Hi-Tech Is Leading The Robotics Revolution.

Novus Hi-Tech is taking a leadership role in defining the future of robots and automation. With cutting-edge Autonomous Mobile Robots (AMRs), AI-based inspection systems, and smart integration platforms, Novus Hi-Tech empowers companies to adopt automation with confidence.

With deep knowledge of robotics trends and scalable automation solutions, Novus Hi-Tech is able to help clients achieve greater productivity while mitigating risk and ultimately realizing operational excellence.

Conclusion: Robotics Trends to Expect in 2025 and Beyond.

The landscape for robots in 2025 will be about intelligence, agility, and sustainability. The automation ecosystem and industry, including collaborative robots, digital twins, and environmentally friendly designs, have accelerated into an epic transformation.

Novus Hi-Tech is leading the way in shaping the future, and it is our privilege to help industries harness automation using the latest robotics advancements. Remember to treat this journey as a marathon and not a sprint; we are learning to run as we go. The companies that apply the most pressure with smart automation today will reap the greatest rewards tomorrow.

FAQs

Q1: What are the 4 types of automation?

The four types of automation are fixed automation, programmable automation, flexible automation, and integrated automation.

Q2: What are the 3 major systems used in industrial automation?

The three major systems are Supervisory Control and Data Acquisition (SCADA), Distributed Control Systems (DCS), and Programmable Logic Controllers (PLC).

Q3: How will AI impact robotics in 2025?

AI will enhance robot autonomy, decision-making, and learning capabilities, enabling smarter, safer, and more adaptive robotic systems.

Q4: What industries will benefit the most from robotics innovations in 2025?

Manufacturing, healthcare, logistics, agriculture, and retail are expected to benefit significantly from the latest robotics innovations.