Introduction

The era of Industry 4.0 has ushered in a wave of intelligent automation, and Autonomous Mobile Robots (AMRs) are at the forefront of this transformation, particularly in Autonomous Mobile Robot Applications. From smart factories to high-speed warehouses, AMRs are changing how materials, components, and even finished products move and operate across sectors.

Their ability to adapt to dynamic environments, navigate intelligently, and collaborate with human operators and machines makes them invaluable in modern industrial settings. In both process and discrete manufacturing, as well as in warehousing and logistics, AMRs are not just an upgrade—they’re a strategic shift toward intelligent, efficient, and scalable operations.

What is an Autonomous Mobile Robot (AMR)?

An Autonomous Mobile Robot (AMR) is a type of robot that uses onboard sensors, cameras, AI algorithms, and navigation systems to move through environments without needing fixed paths or manual control. Unlike traditional AGVs (Automated Guided Vehicles), which rely on magnetic strips or tracks, AMRs dynamically map and navigate their environment in real-time.

They offer:

This makes AMRs ideal for a wide range of tasks—from material handling and bin transfer to parts assembly and inspection—across a variety of industries.

How Do AMRs Navigate Inside Factories and Warehouses?

AMRs rely on advanced Simultaneous Localization and Mapping (SLAM) algorithms, fusing data from LiDAR, cameras, IMUs, and proximity sensors to map and navigate spaces. Unlike AGVs that follow fixed routes, AMRs autonomously detect changes in the environment (like temporary obstructions or personnel movement) and intelligently re-route in real-time.

They connect to centralized fleet management systems that coordinate tasks, assign optimal routes, monitor battery levels, and manage charging cycles. These capabilities make them ideal for complex, non-linear workflows in dynamic environments.

Discover how Autonomous Mobile Robot applications boost industrial efficiency.

Download our free brochure for expert insights and trends!

Top 13 Autonomous Mobile Robot Applications in Industries

Here are the top 13 industrial Autonomous Mobile Robot applications where AMRs are making a transformative impact:

1. Assembly Line Automation (Discrete Manufacturing)

AMRs are replacing traditional conveyors and fixed line automation. They carry components between workstations, bring fixtures to operators, and enable flexible, reconfigurable production lines. Ideal for:

- Automotive assembly

- Electronics manufacturing

- Appliance and tractor production

Watch AMR in action here – AMR application

2. Intralogistics Material Movement (Warehousing + Manufacturing)

AMRs automate the internal flow of materials, handling trolleys, pallets, bins, or kits between stores, production, and dispatch. They’re transforming:

- Raw material transfer

- Semi-finished product movement

- Finished goods transportation

3. Ground-to-Ground Trolley & Pallet Transfer

In sectors like FMCG and pharmaceuticals, AMRs replace forklifts by safely transporting pallets and trolleys from stores to lines or lines to packing stations. This reduces human error and improves floor safety.

4. Bin Transfer: Conveyor-to-Conveyor & Point-to-Point

AMRs integrated with conveyor systems or smart racks enable automated bin collection and delivery, facilitating just-in-time (JIT) supply in manufacturing and kitting processes.

5. Line Feeding & Kitting

AMRs support lean manufacturing by supplying parts kits to specific workstations exactly when needed. They pick and deliver based on production schedules and MES data, eliminating manual errors and downtime.

6. Finished Goods Handling to Warehouse

Post-production, AMRs handle finished goods transfer from production lines to the warehouse, ensuring traceability, optimized storage, and smooth outbound logistics.

7. End-of-Line Handling & Inspection

AMRs equipped with vision systems or robotic arms can carry out end-of-line inspection and then transfer products to the appropriate locations based on quality outcomes (pass/fail/rework zones).

8. Multi-floor Transfers with AMR + Lift Integration

In multi-level warehouses or plants, AMRs integrate with elevators/lifts for inter-floor transportation, reducing manual effort and enabling true vertical scalability.

9. Tool Handling and Transfer

In precision industries like aerospace or defense manufacturing, AMRs automate the delivery of jigs, fixtures, and tools, reducing downtime due to misplaced or late tool deliveries.

10. Autonomous Tugging and Tunneling Applications

AMRs with tugging/tunneling attachments pull multiple trolleys in convoy, ideal for repetitive routes like stores to line or warehouse to dispatch, reducing dependency on forklifts and tuggers.

11. Cold Chain and Cleanroom Logistics

Specially designed AMRs handle sensitive goods in cold storage or cleanroom environments (like pharma or semiconductor industries), maintaining hygiene and temperature protocols.

12. Hazardous Environment Applications

In industries dealing with chemicals, flammables, or high heat zones, AMRs enable safe, remote material handling, protecting human workers and maintaining compliance.

13. Warehouse Order Picking and Putaway

For warehouses, AMRs assist in order picking, shelf replenishment, and putaway tasks—either independently or in collaboration with human operators or robotic arms.

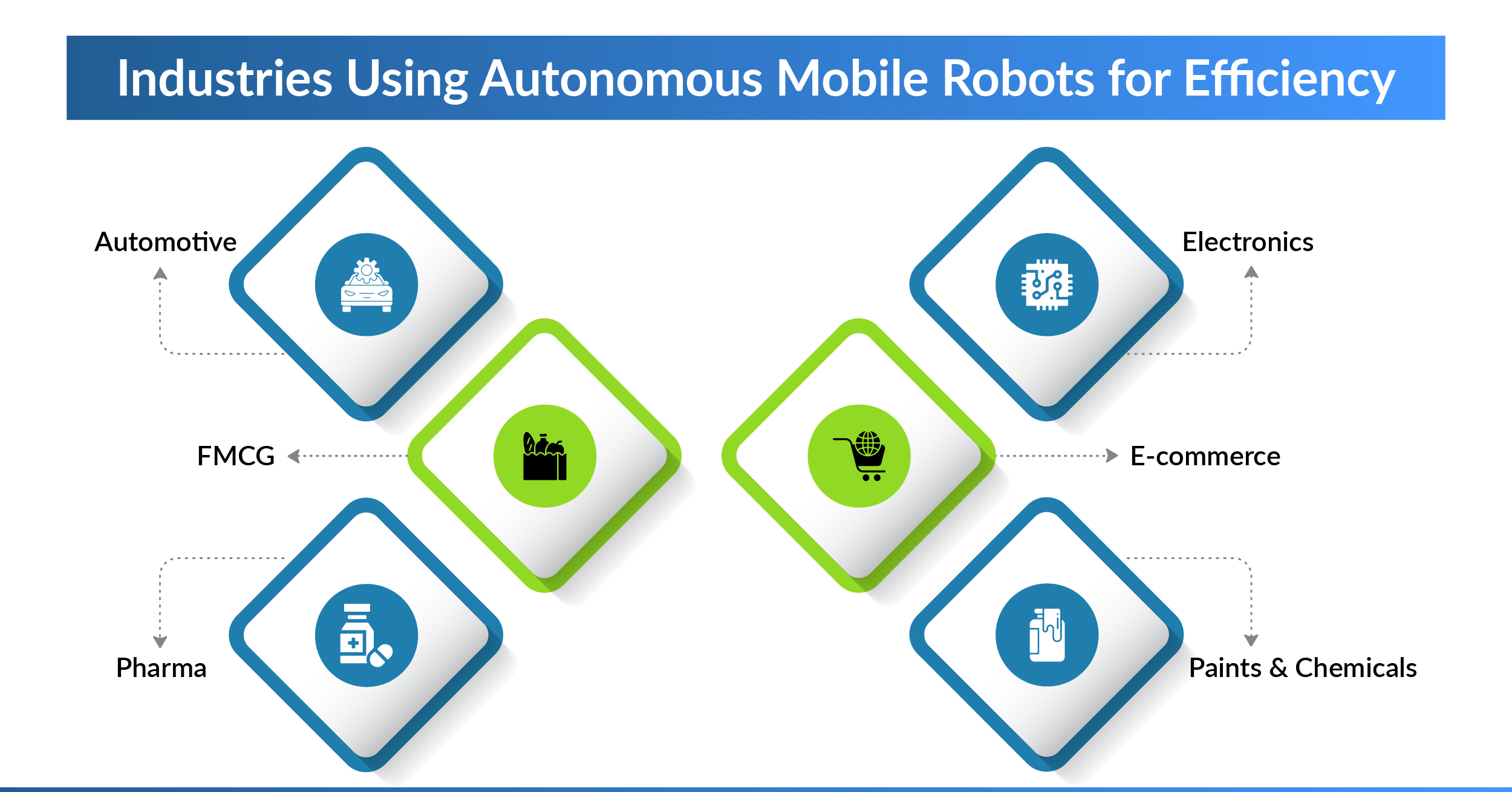

Industries Using Autonomous Mobile Robots for Efficiency

AMRs are being deployed across a broad range of industries, including:

- Automotive: Engine assembly, chassis kitting, line feeding

- FMCG: Raw material and FG transfer, dispatch prep

- Pharma: Bin and batch transfer under GMP conditions

- Electronics: High-precision tool handling and material flow

- E-commerce: Smart warehouses, picking, and delivery

- Paints & Chemicals: Intrinsically safe operations in hazardous zones

The Environmental Impact of Autonomous Mobile Robots

By replacing fossil-fuel-driven material movers (like forklifts), AMRs contribute to:

- Lower carbon emissions

- Reduced energy waste through smart routing

- Less material wastage via precise handling

- Space optimization, allowing compact layouts and fewer travel miles

They align with sustainability goals and green factory initiatives.

How Autonomous Mobile Robots Are Transforming Factory & Warehouse Automation

Traditional automation was rigid. AMRs usher in a software-defined era where layout changes, process upgrades, and production shifts can be accommodated on the fly. Key benefits include:

AMRs are the foundation of the Factory of the Future—smart, flexible, and AI-driven.

Final Thoughts

Autonomous Mobile Robots are not just machines. They are digital co-workers — working 24/7 to move your factory or warehouse into the future. Whether you’re looking to boost productivity, enhance safety, or lower operational costs, AMRs offer a transformative solution.

And with Novus Hi-Tech, you don’t just get robots — you get a partner who understands your industry, your floor, and your challenges.

Let’s build the smartest, safest, and most sustainable factories of tomorrow.

Why Choose Novus Hi-Tech for AMR Solutions?

At Novus Hi-Tech, we are not just building robots — we are engineering the future of intelligent manufacturing. Our Autonomous Mobile Robots (AMRs) are designed with a software-first philosophy, enabling rapid adaptability, seamless scalability, and high levels of precision in dynamic factory and warehouse environments.

With 100+ successful industrial deployments across automotive, FMCG, pharma, engineering, and more, Novus AMRs have transformed traditional operations by:

- Replacing manual and conveyor-based systems with flexible, grid-based movement

- Delivering measurable improvements in material flow, safety, and productivity

- Supporting both brownfield retrofits and greenfield rollouts with ease

- Operating through a unified platform that ensures real-time visibility and control

Our industry-proven solutions have helped customers reduce material handling costs & boost throughput by and achieve zero-accident operations in high-risk zones.

We don’t just deploy robots — we partner with you to future-proof your operations.

👉 Schedule a Live Demo or Site Assessment Today

📩 Reach us at marketing@novushitech.com