Warehousing AMR is currently experiencing rapid and accelerated change. Increased demands for speed, accuracy, and efficiency make traditional methods and systems for handling these operations obsolete. The demand for integrated technology solutions that are meant to provide real-time intelligence, scalability, and efficiency is being accelerated; Autonomous Mobile Robots in warehouses are changing the entire operational paradigm of AMR warehouse automation as we know it.

AMRs are changing entire industries from materials handling, inventory accuracy, and beyond… AMRs are doing these jobs faster and with more accuracy than any human can ever achieve, and with complete autonomy (disregarding repetitive, human exception behaviours). While intelligent systems are driving autonomous robots within the logistics world, these autonomous warehouse robots are transforming the way a modern warehouse can operate, increasing workflow, safety, and efficiencies in the operation.

What Are Autonomous Mobile Robots (AMRs)?

The growth of Warehouse AMR technology is exhilarating, and many of its developments are accelerating. The increasing need for speed, accuracy, and flexibility is exploding traditional warehouse processes. We need integrated, intelligent technology that allows for real-time visibility, speedy adaptability to changing conditions, and provides continuous availability. Autonomous Mobile Robots (AMRs) will be part of the foundation and part of the future of warehouse automation technology.

These autonomous robots in a warehouse are moving beyond supporting solutions to transformational alternatives that embody processes. AMRs have enhanced the level of inventory accuracy, speed of material handling, and are more consistent in executing material handling activities in comparison to humans; AMRs often outperform human operational capacity and reliability. Where human-operated manual workflows can fail to deliver and fall behind, autonomous/battery-operating automated robots (AMR) in warehouse work can work as a fully autonomous robot, which includes real-time navigation of work sites, avoiding obstacles, and optimizing their path as they work.

One of the areas seeing some of the biggest changes is pallet transport through AMRs, representative of their faux forklift design as autonomous battery-operated pallet trucks (ABOPTs). Studies have demonstrated that ABOPTs outperform forklifts as they independently lift and move palletized loads within the “Four-wall” of the warehouse, while simultaneously providing an alternative to the dwindling pool of permitted freight lift truck operators. In addition to their autonomous promise warehouse safety, ABOPTs can facilitate inter-zone transfer despite having limitations on distance travelled compared to external forklifts.

In summary, AMRs are the future of warehouse automation to meet the growing demand for scalable, intelligent, autonomous logistics.

Key Functions of AMRs in Warehousing

Autonomous Mobile Robots (AMRs) have many capabilities associated with the warehouse process; these include:

Pallet Transport Using AMRs with Forklifts

AMRs designed to serve industrial needs, such as Autonomous Battery Operated Pallet Trucks (ABOPT), can autonomously lift and move palletized goods across warehouse zone buildings. This application is ideal for moves between stations, inbound and outbound docks, and in cold or freezer storage environments. AMRs reduce the need for people to operate manual forklifts, providing improved safety and productivity.

Order picking and item retrieval

In addition to moving items, when paired with Warehouse Management Systems (WMS), the AMR can autonomously pick up items from shelving storage. This allows for more timely order picking and a more accurate method of order fulfillment.

Shelf scanning and inventory tracking

AMRs can have various barcode/RFID scanners and sensors to perform inventory checks in near real-time while progressing through different onboarding methods. In other words, an AMR can review stock levels while moving at a quicker pace and more accurately, while making it crossroads inventory that can be identified with discrepancies in real-time.

Sorting and Zone-to-Zone Transfers

AMRs sort parcels or products by category, destination, or type, and deliver them to designated zones. This increases throughput and improves overall logistics coordination.

By handling these core functions efficiently, AMR warehouse automation significantly boosts productivity and reduces bottlenecks.

As AMRs execute these primary functions, it is providing fabricate an effective automation process to allow for a more efficient warehouse process and initiate better productivity while alleviating bottlenecks.

Discover how Warehouse AMRs transform logistics efficiency.

Download our free brochure for expert insights and trends!

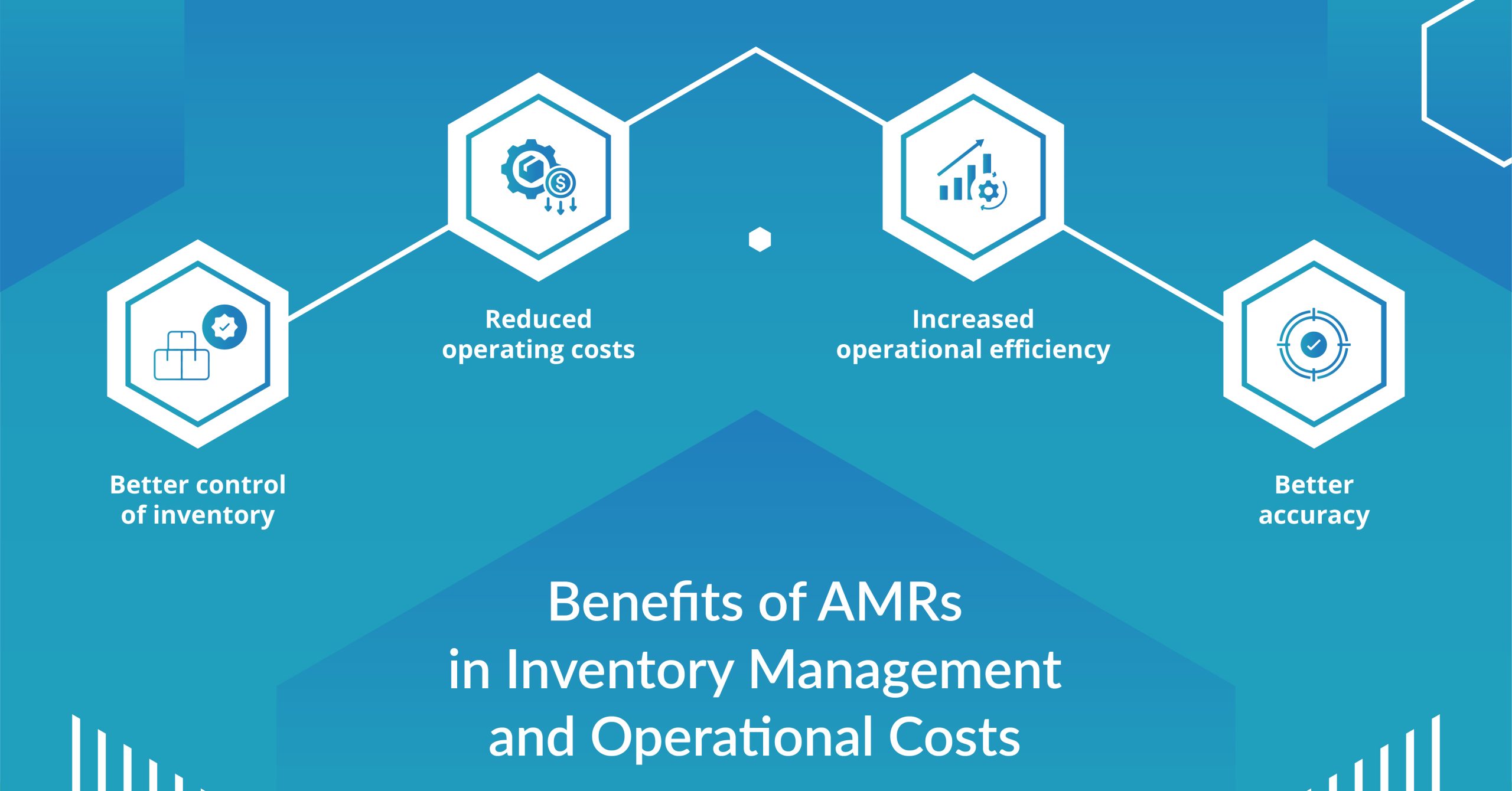

Benefits of AMRs in Inventory Management and Operational Costs

Incorporating automated robots in a warehouse has both hard and soft benefits. This is how AMRs optimize warehouse operations:

✅ Better control of inventory

With sensor-based scanning and systems integrated to your ERP/WMS, AMRs provide visibility of your stock in real-time. This allows for in-the-moment updates, which drastically reduce stock-out occurrences, over-stocking, and human error.

✅ Reduced operating costs

AMRs lighten the load of full-time manual labor from routine procedures. Additionally, they also minimize the frequency of errors that result in product damages, costs from returns, or delays in shipping.

✅ Increased operational efficiency

AMRs have 24/7 availability, limit fatigue, and can isolate high-frequency tasks, leading to higher-order fulfillment speed and a smoother logistics flow.

✅ Better accuracy

With the absence of human intervention, we can increase the accuracy of picking, placement, and routing. All essential in the e-commerce and automotive industries lack tolerance for mistakes.

Real-World Applications and Case Studies

From retail to automotive logistics, AMRs and their companions are changing warehouse performance metrics. Take the example of a high-volume e-commerce fulfillment center during peak season.

AMRs are autonomously retrieving items instead of intruding and taking away the excitement and thrill from clamoring and overwhelmed staff; they are retrieving items and bringing items to a packing station, and even restocking returned items—all while decreasing errors by 40% and improving fulfilment time (footprint) by 3x.

On the automotive side, AMRs and ABOPTs are moving heavy components and pallets between assembly lines with no reactionary disturbance to a lean manufacturing concept. AMRs accomplish similar tasks to those seen in cold storage applications, where the same tasks are too difficult or dangerous for humans.

Even if your operation does not get to the size and scale of Amazon or Flipkart, you will see measurable improvements—and enhancements—through the use of AMR robots in your warehouse, regardless of your warehouse’s size.

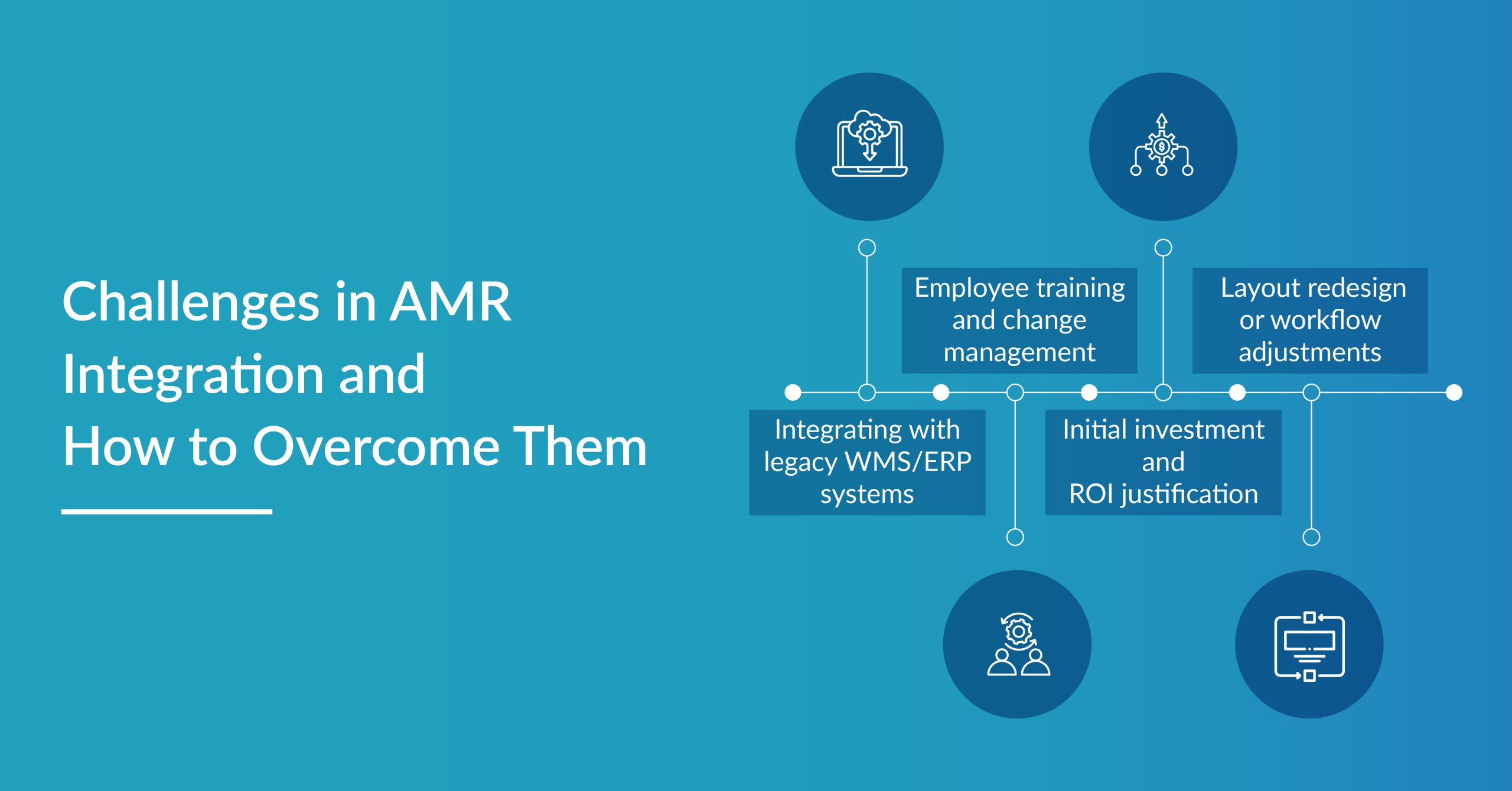

Challenges in AMR Integration and How to Overcome Them

Ok, so while AMRs have upside potential, your company may face drawbacks when getting through the early stages of accepting the new technology. Here are some suggestions on how to start addressing some of the early concerns.

Integrating with legacy WMS/ERP systems

Quite a few warehouses continue to utilize legacy WMS / ERP systems. You can bypass this issue by focusing on AMRs with modular API support, like Novus Hi-Tech, that can integrate with most legacy or current systems.

Employee training and change management

Automating routine tasks generates anxiety and pushback. Companies need to incorporate change management processes and financing as part of employee onboarding and training procedures, transitioning employees from manual positions to technician or supervisor positions.

Initial investment and ROI justification

Any purchase you make, and AMRs have an upfront capital outlay, will have an expected return on investment. Organizations typically anticipate a return on investment within 12-18 months that comes from labor offsets, fewer errors, and efficiency in the process.

Layout redesign or workflow adjustments

Some locations may have drastically different layouts that need to be addressed for AMRs to move with efficiency. One way to resolve this is by building multiple AMRs in your fleet that can be utilized based on the needs of your location, which are manageable through the Novus level of planning.

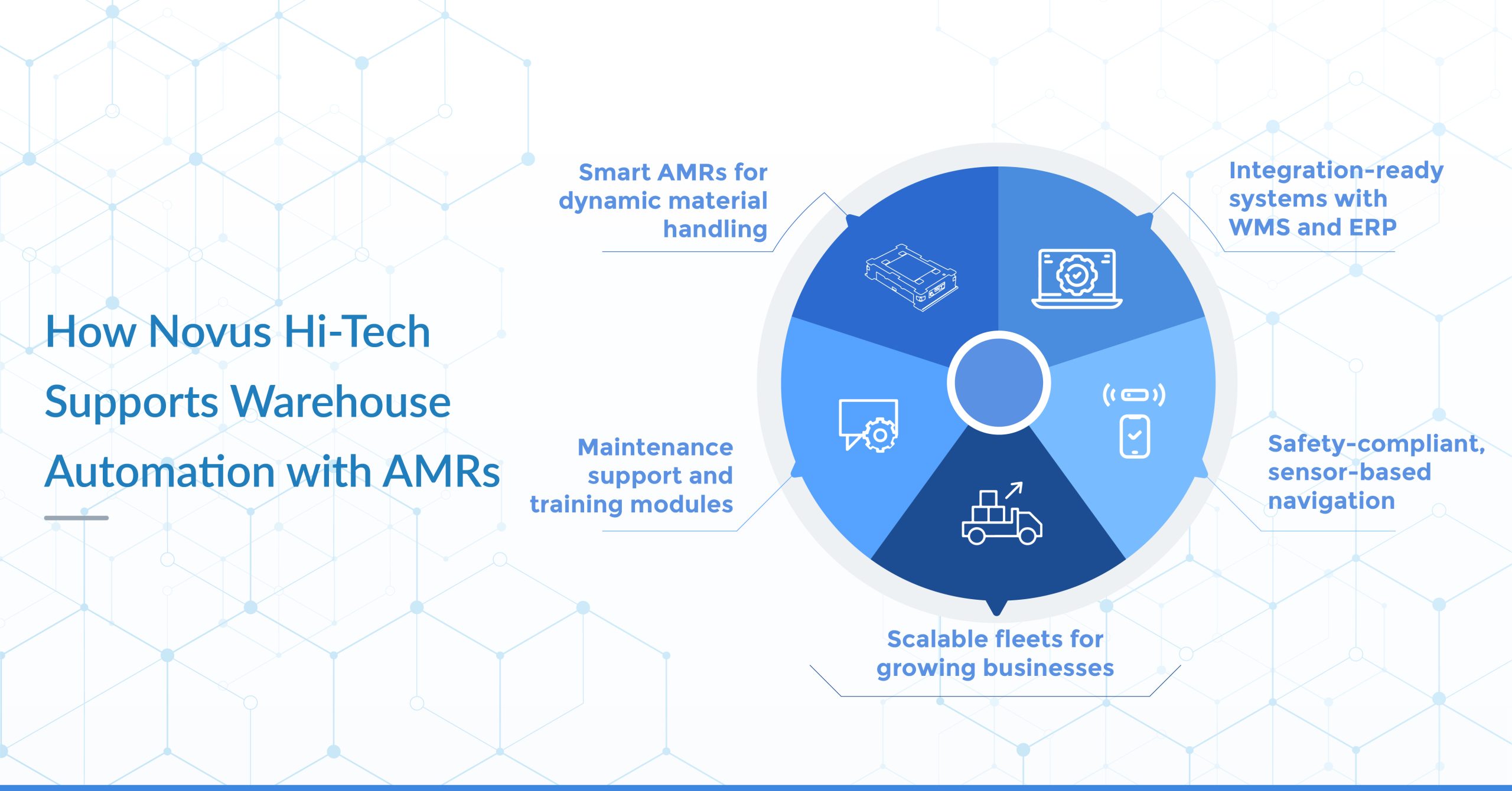

How Novus Hi-Tech Supports Warehouse Automation with AMRs

Novus Hi-Tech provides a full suite of AMR solutions customized for modern warehouses that prioritize innovation, safety, and scalability to create a sustainable Novus Way of automation.

Smart AMRs for dynamic material handling

Novus produces Autonomous Battery-Operated Pallet Trucks (ABOPT) for high-volume warehouses with bulk movement capabilities, from light item pick-ups to heavy-load pallet movement.

Integration-ready systems with WMS and ERP

Novus AMRs are ready to integrate with today’s leading WMS and ERP systems for synchronization with operational workflows.

Safety-compliant, sensor-based navigation

Novus AMRs checked all the safety boxes with obstacle detection, laser navigation, and 360-degree lidar sensors while complying with international safety regulations, and are effective in human-populated workplaces.

Scalable fleets for growing businesses

No matter how big or small, one warehouse or a multi-location logistics hub, Novus is flexible in fleet sizing to accommodate your growth.

Maintenance, support, and training modules

A Novus automation journey means end-to-end support throughout your entire automation journey, including layout consideration, worker training, and scheduled maintenance. Novus has your back!

Conclusion

Warehouse AMRs are no longer speculative; they now represent intelligent logistics today. AMRs can help make warehouses and supply chains more efficient, accurate, and cost-effective in real-time inventory, the use of products and materials.

As supply chain complexity and competition increase, autonomous mobile robots in warehouses will be key to building agile, future-ready supply chains.

If you are planning to automate an existing warehouse or warehouse operation, now may be a good time to investigate AMR warehouse automation and have a partner like Novus Hi-Tech make the transition for you in a seamless and scalable way.

FAQs

1. How do AMRs differ from traditional warehouse robots?

AMRs can work autonomously without fixed routing and tracking. They use onboard sensors and load mapping to travel from Point A to Point B – something traditional AGVs or robots are not made to do.

2. How long does it take to integrate AMRs into existing systems?

Implementation will vary due to the size of the operation and the complexity of the warehouse. Implementation can take anywhere from 2 weeks to 8 weeks, specifically if utilizing integration-ready hardware, such as the Novus AMRs.

3. Are Novus Hi-Tech AMRs customizable for specific warehouse tasks?

Yes, Novus can develop AMRs that can perform different applications relating to material handling, inventory, and picking, as well as integrate ABOPT solutions for pallet transport.

4. What safety features do AMRs include?

Novus AMRs include collision detection, 360-degree sensors, automatic re-routing, and SOS to help preserve human safety.