In the ever-evolving landscape of industrial automation, AGV robots (Automated Guided Vehicles) stand as vital assets driving efficiency, safety, and productivity across various industries. From manufacturing floors to warehouses, the versatility and functionality of AGV mobile robots have revolutionized traditional material handling processes. Let’s delve into the world of AGVs, exploring what they are, their types, applications, benefits, operational mechanisms, considerations in choosing an AGV robot manufacturer, future trends, and why they are crucial for modern industries.

What is an AGV?

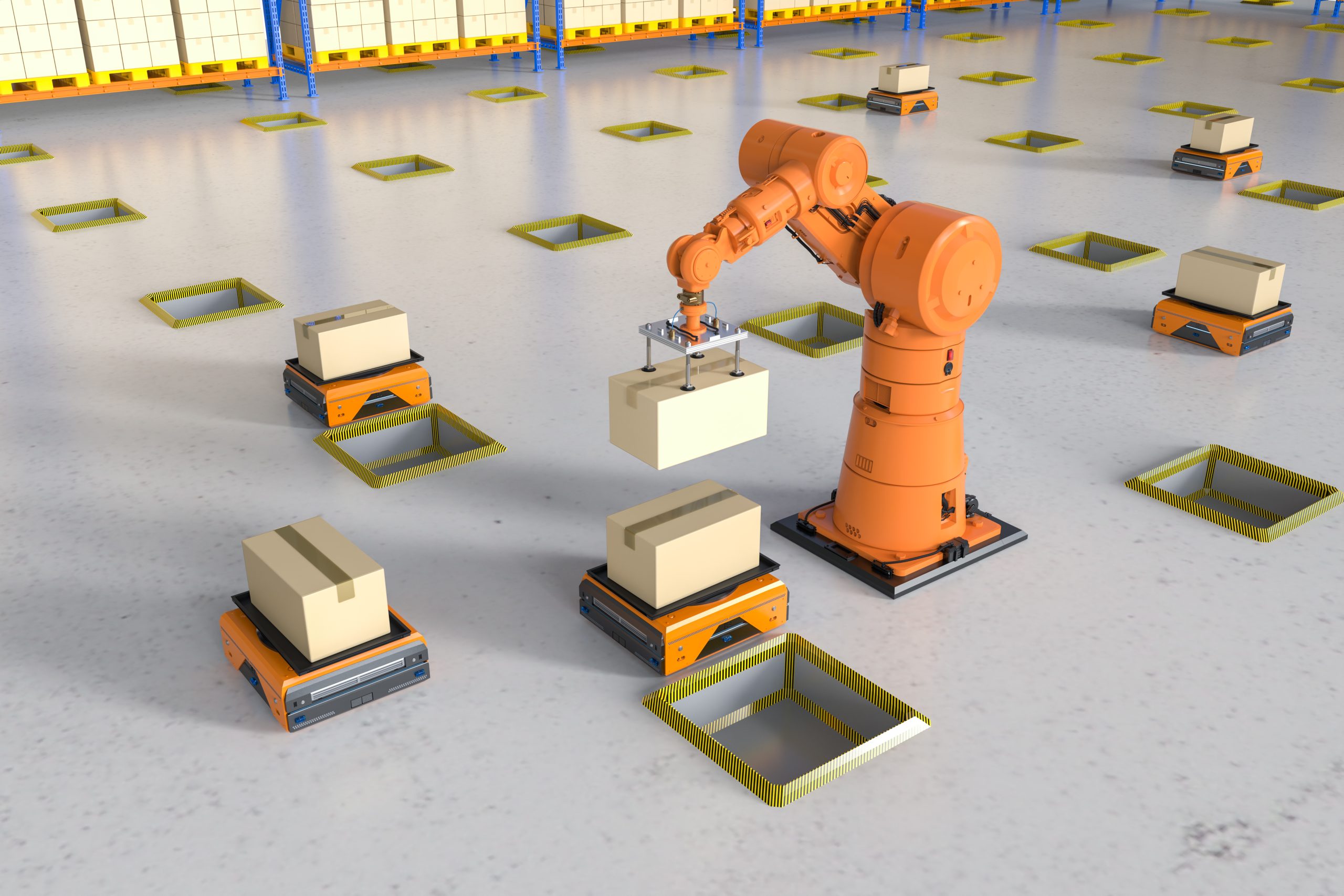

AGVs are autonomous vehicles equipped with guidance systems and sensors to navigate predefined routes within industrial environments, transporting materials and goods without human intervention. These AGV mobile robots operate efficiently, enhancing workflow and minimizing manual labor.

AGVs utilize a combination of technologies for navigation, such as laser guidance, magnetic tape, or vision systems, enabling them to traverse safely within their designated areas. These systems allow AGVs to detect obstacles, follow paths accurately, and interact with other equipment or machinery seamlessly.

Discover how Automated Guided Vehicles (AGVs) drive the future of automation.

Download our free brochure for expert insights and trends!

Types of AGVs

- Towing AGVs: These robust vehicles excel in pulling heavy loads across manufacturing facilities and warehouses. They are commonly used in industries requiring the transportation of large and bulky items.

- Unit Load AGVs: Specifically designed for transporting single units or pallets, unit load AGVs streamline logistics operations by efficiently moving materials from one location to another.

- Forklift AGVs: With lifting capabilities, forklift AGVs facilitate seamless loading and unloading of pallets, optimizing warehouse operations and reducing manual handling.

- Hybrid AGVs: Combining features of various AGV types, hybrid AGVs offer versatility and flexibility, adapting to diverse operational requirements within industrial settings.

Common Applications of AGVs

AGVs find extensive applications in industries such as manufacturing, warehousing, and logistics:

- Material Handling: AGVs efficiently transport raw materials, components, and finished products within production facilities, contributing to streamlined workflows and reduced cycle times.

- Transportation: They play a vital role in moving goods between different areas of a warehouse or distribution center, ensuring timely delivery and inventory management.

- Assembly Line Support: AGVs streamline assembly processes by delivering components to designated workstations, optimizing production efficiency, and minimizing downtime.

Benefits of AGVs

The adoption of AGV robots offers numerous benefits across various industries:

- Enhanced Efficiency: AGVs operate 24/7, reducing material handling time and optimizing resource utilization, leading to increased productivity and throughput.

- Improved Safety: Equipped with advanced sensor technologies, AGVs navigate safely around obstacles, minimizing the risk of accidents and ensuring a safer working environment for employees.

- Cost-Effectiveness: By automating material handling tasks, AGVs reduce labor costs and increase operational efficiency, resulting in significant cost savings over time.

How AGVs Work

AGVs rely on a combination of sensors, navigation systems, and software algorithms to operate autonomously within industrial environments. These systems enable AGVs to:

- Detect Obstacles: AGVs utilize sensors such as lasers, cameras, or ultrasonic sensors to detect obstacles in their path and make real-time adjustments to avoid collisions.

- Follow Paths: AGVs follow predefined paths or routes using guidance systems such as magnetic tape, markers, or virtual walls, ensuring accurate navigation within their designated areas.

- Interact with Equipment: AGVs can interact with other equipment or machinery, such as conveyors or loading docks, to facilitate seamless material handling processes.

Choosing an AGV Robot Manufacturer

When selecting an AGV robot manufacturer, several factors should be considered to ensure a successful implementation:

- Reputation: Choose a reputable AGV robot manufacturer with a proven track record of delivering high-quality products and reliable customer service.

- Customization Options: Look for an AGV robot manufacturer that offers customizable solutions tailored to meet your specific operational requirements and challenges.

- After-Sales Support: Ensure that the AGV robot manufacturer provides comprehensive after-sales support, including maintenance services, technical assistance, and training programs.

Novus Hi-tech stands out as a reliable partner in the field of industrial robotics, offering innovative AGV solutions designed to optimize material handling processes and drive operational efficiency. With our commitment to excellence and customer satisfaction, we empower businesses to embrace the future of automation with confidence.

Future Trends in AGVs

The future of AGV robots is marked by ongoing advancements and emerging trends in technology and innovation:

- AI Integration: AGVs are increasingly incorporating artificial intelligence (AI) technologies to enhance decision-making capabilities, optimize route planning, and improve operational efficiency.

- Enhanced Navigation: Future AGVs will feature advanced navigation systems, such as simultaneous localization and mapping (SLAM), enabling them to navigate more efficiently in dynamic and complex environments.

- Increased Efficiency: AGVs will continue to evolve to meet the growing demands for increased productivity, throughput, and flexibility, driving further automation and optimization in industrial operations.

Novus Hi-tech remains at the forefront of innovation in AGV technology, continuously exploring new possibilities and pushing the boundaries of what is possible in industrial automation.

Conclusion

In conclusion, AGV robots represent not just a technological innovation but a paradigm shift in industrial automation. Their seamless integration into various sectors has propelled efficiency, safety, and productivity to unprecedented levels. As industries continue to evolve and embrace the digital age, the significance of AGVs as indispensable assets becomes increasingly apparent. With Novus Hi-tech leading the charge in AGV technology, businesses can confidently navigate the complexities of modern manufacturing and logistics landscapes.

As we look to the future, the role of AGVs will only expand, fueled by advancements in AI, navigation, and integration capabilities. Novus Hi-tech remains committed to staying at the forefront of these developments, delivering cutting-edge solutions that redefine industry standards. By partnering with Novus Hi-tech, businesses can not only adapt to the demands of today but also anticipate and capitalize on the opportunities of tomorrow. Embrace the future of automation with Novus Hi-tech and unlock a world of possibilities for your business. Together, let’s shape a future where efficiency, safety, and innovation converge seamlessly in the realm of industrial robotics.

FAQs

- What are AGVs used for?

AGVs are used for autonomously transporting materials and goods within industrial environments, enhancing efficiency and productivity. - How do AGVs navigate?

AGVs navigate using a combination of guidance systems, sensors, and software algorithms to follow predefined routes or dynamically adapt to changing environments. - What industries benefit most from AGVs?

Industries such as manufacturing, warehousing, and logistics benefit the most from AGVs due to their efficiency in material handling processes. - What is the difference between AGVs and AMRs?

AGVs follow predefined routes, while AMRs (Autonomous Mobile Robots) operate more flexibly, navigating autonomously in dynamic environments. - How safe are AGVs?

AGVs are equipped with advanced sensor technologies to detect obstacles and ensure safe navigation, minimizing the risk of accidents. - Can AGVs be customized for specific tasks?

Yes, AGVs can be customized to meet specific operational requirements, offering flexibility and adaptability in various industrial settings. - What is the cost of implementing AGVs?

The cost of implementing AGVs varies depending on factors such as the type of AGV, customization requirements, and the size of the deployment. - How do AGVs improve efficiency?

AGVs improve efficiency by automating material handling tasks, reducing manual labor, and optimizing resource utilization. - Are AGVs suitable for small businesses?

Yes, AGVs can benefit small businesses by streamlining material handling processes, enhancing efficiency, and reducing operational costs. - What maintenance do AGVs require?

AGVs require regular maintenance, including software updates, sensor calibration, and mechanical inspections, to ensure optimal performance and reliability. - How do AGVs impact labor needs?

AGVs reduce the dependency on manual labor for material handling tasks, reallocating human resources to more critical and complex activities.

By effectively integrating AGV robots into your operations, you can unlock new levels of productivity and efficiency. Whether you’re curious about what an AGV is or seeking the benefits of AGV technology, Novus Hi-tech is your trusted AGV robot manufacturer, leading the way in the future of industrial automation.