The automotive manufacturing is changing in a significant way, not solely because of technology and innovation, but largely driven by necessity. We will be in 2025, and automation for automotive manufacturing will no longer be a competitive advantage; it will be a requirement.

With globalization, increased demands for production, and greater demands for demand, with continued labor shortages and sustainability goals, manufacturers have been forced to rethink old practices.

Smart technologies utilizing collaborative robots, smart sensors, edge computing, and autonomous mobile robots (AMRs) are transforming automotive manufacturing, including the automotive assembly line, which is rapidly becoming more intelligent, flexible, and productive.

Why Automation Is No Longer Optional in Automotive Manufacturing

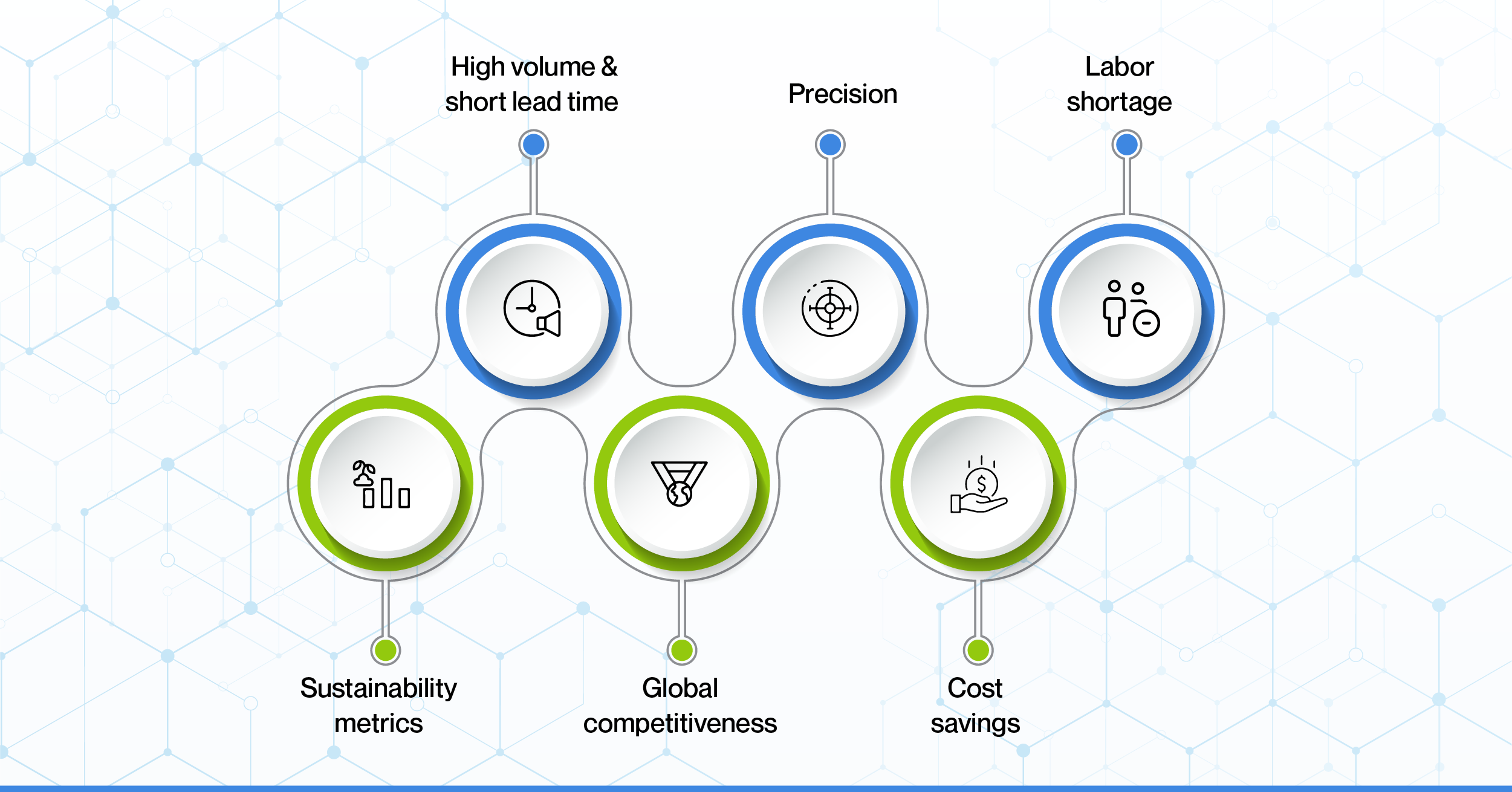

While it remains unclear if we can value human life in monetary terms, the pace of change in automotive manufacturing should not bind our thoughts to humans or outdated methodologies. We must start with the adoption of automation if we wish to be competitive by 2025:

High volume & short lead time – Electric and connected vehicles are driving a demand for speed and scalability on most orders.

Precision – Quality control, safety, repeatability over thousands of parts, will require smart automation.

Labor shortage – Skilled labor is increasingly rare, and automation can help with some of the labor gaps and lessen reliance on human inputs.

Sustainability metrics – Automation can help us reach our ESG targets to lower emissions, waste, and energy consumption.

Global competitiveness – OEMs need efficiency and flexibility to globalize their production, and automation can help them achieve this.

Cost savings – Automated systems help reduce mistakes, downtime, and operating material resources, all in the name of greater long-term savings.

Discover the latest innovations in Automotive Manufacturing.

Download our free brochure for expert insights and trends!

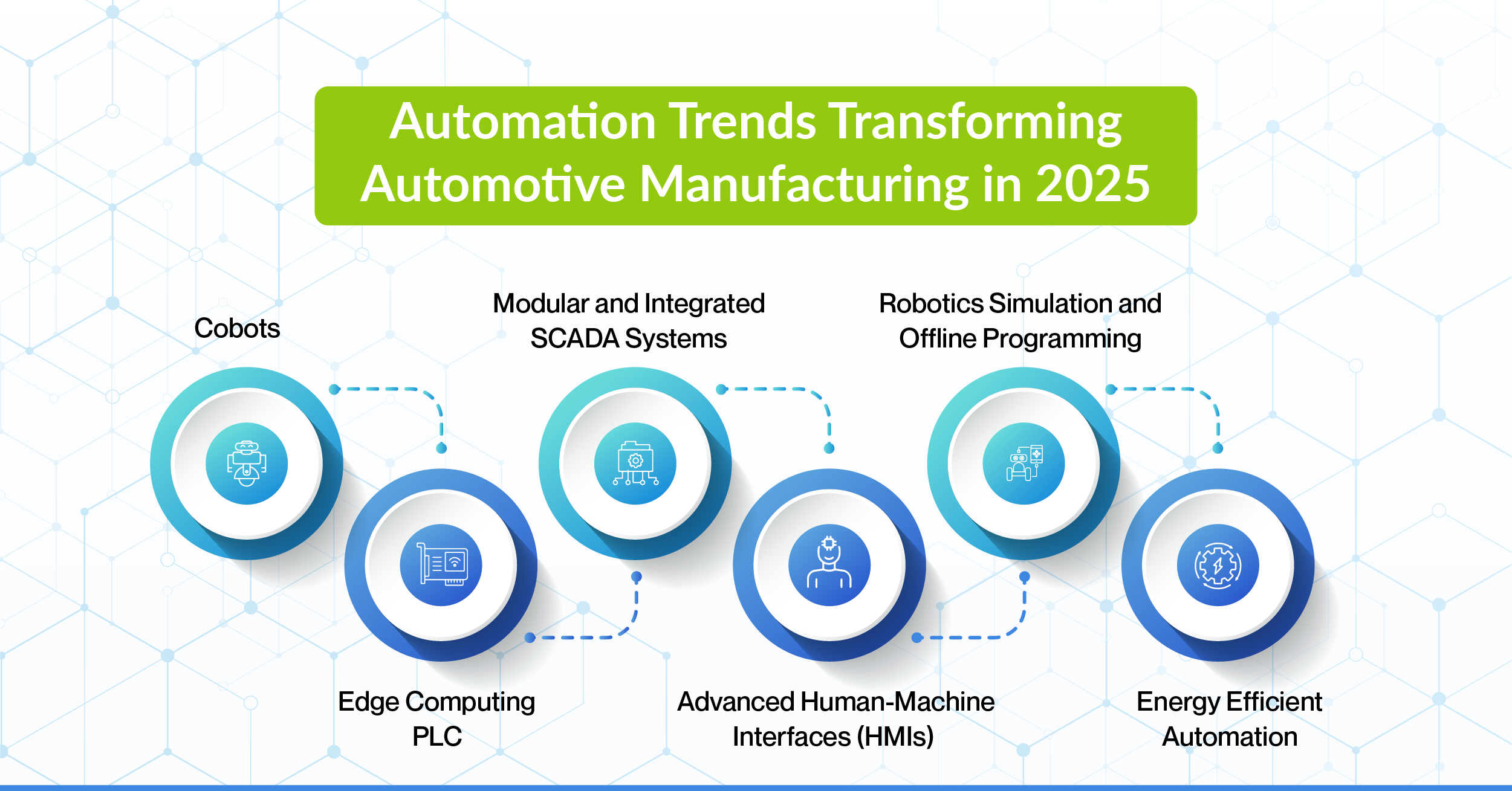

Automation Trends Transforming Automotive Manufacturing in 2025

1. Cobots

While traditional industrial robots tend to operate in a separate space from humans, collaborative robots (or “cobots”) are breaking down the boundaries that have traditionally existed on the automotive assembly line. Cobots will operate in many different ways, operating alongside humans as well as accurately directing processes like welding, fastening bolts, and assembling parts, employing maximum throughput while protecting the human worker.

In combination with advanced vision systems, Novus Hi-Tech enables a standard cobot to have edge processing capabilities and will increase the cobot’s ability to function and dramatically speed the workflow.

2. Edge Computing PLC

Edge computing is starting to develop as a key area for the automotive manufacturing industry. Prior to edge computing, manufacturers depended on cloud-based controls for automotive assembly line systems. Edge PLC (Programmable Logic Controllers) do rely on and use cloud-based data/analytics, but the key differences are that they run it at the factory site, rather than remote situation. This can give an instantaneous ability to assess machinery performance and cycle times as well as low-latency performance on mission-critical decisions, since everything is occurring in real-time.

Novus Hi-Tech’s edge-ready logic controllers provide manufacturers with near-instantaneous situation reports, giving machines the ability to reach peak performance, and with the final end-user/customer experience.

3. Modular and Integrated SCADA Systems

Modular SCADA (Supervisory Control and Data Acquisition) systems offer manufacturers flexibility and scalability by integrating their functionalities (temperature, health of machines, material flows, etc.) into a single interface that both provides better response times and has the potential to reduce downtime.

The Novus Hi-Tech SCADA system was built upon a modular design to allow for the scaling of operations, so that when a SCADA application is expanded, it can do so easily.

4. Advanced Human-Machine Interfaces (HMIs)

No more fixed control panels. Now operators are controlling operations through intuitive touchscreen-based HMIs, allowing visibility over a process that can become quite complicated, whilst providing options for operators to engage when they want or need to. Real-time feedback, alerts to production faults, and real-time metrics on production are now giving operators better information and the ability to respond faster when needed.

5. Robotics Simulation and Offline Programming

Manufacturers are utilizing simulation tools to walk through workflows, identify bottlenecks, and optimize layouts before deploying robots on the floor, of course, without interfering with production. Offline programming enables faster changeover and faster commissioning of robotic systems in order to reduce downtime and provide a longer-term efficiency approach.

6. Energy Efficient Automation

Sustainability is much more than a buzzword – it’s now a business imperative. Modern automation systems have a variety of energy-efficient drives, sensors that can measure their energy usage, and optimization algorithms designed to lower their energy consumption. Novus Hi-Tech incorporates carbon footprint reductions into its work as a central goal, and designs its production lines for leaner, cleaner processes.

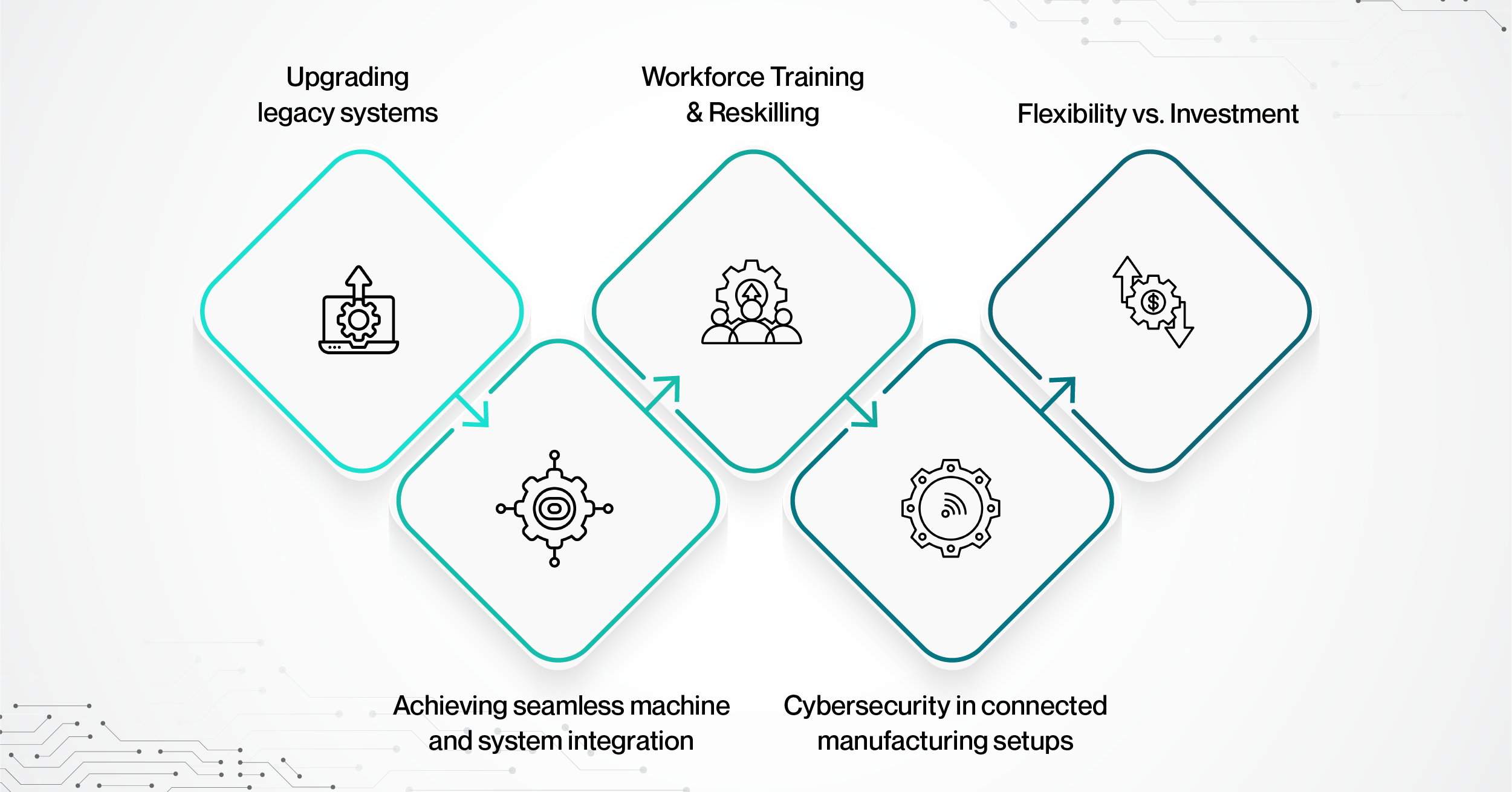

Key Challenges in Automotive Automation (And How to Overcome Them)

The issues with introducing automation to existing legacy systems. It can be very complicated. It can be useful to have upgradeable architectures & open protocols.

Upgrading legacy systems:

Getting robots, PLCs, HMIs, and software systems to work seamlessly requires experienced planning and work to coordinate multiple vendors.

Achieving seamless machine and system integration:

Further engagement and education will be required to move people from manual jobs to supervisory or analytical jobs.

Workforce Training & Reskilling:

Workers must transition from manual roles to supervisory or analytical roles, requiring ongoing training.

Cybersecurity in connected manufacturing setups:

Connected factories are at risk of being hacked. New, rigorous IT-OT (Information-Operation Technology) security regimes will need to be installed.

Flexibility vs. Investment:

Striking the right balance between capital investment and long-term flexibility is a strategic necessity.

Choosing between in-house and outsourced automation implementation

Depending on skill availability and timelines, companies must assess whether to build automation internally or partner with experts like Novus Hi-Tech.

Build it yourself or use experts: All companies should be able to determine, based on staff expertise and the time required to be successful, if their next step is to build it themselves or if they need very capable expertise like that developed at Novus Hi-Tech to collaborate with.

The ROI of Automotive Automation: What to Expect

The smart use of automation can deliver a strong return on investment when planned properly. This can be measured by:

- Lower labor costs. Automated processes should reduce or eliminate the need for human labor in risky, repetitive tasks.

- Higher throughput. Increased speed leads to higher overall production rates.

- Lower defective rate. Vision systems and smart sensors can help cut down on errors.

- Predictive maintenance. Real-time monitoring can lower unexpected failures and extend equipment life.

- Possible KPIs include MTBF (mean time between failures), OEE (overall equipment effectiveness), production rate, energy cost per unit, and defective rate.

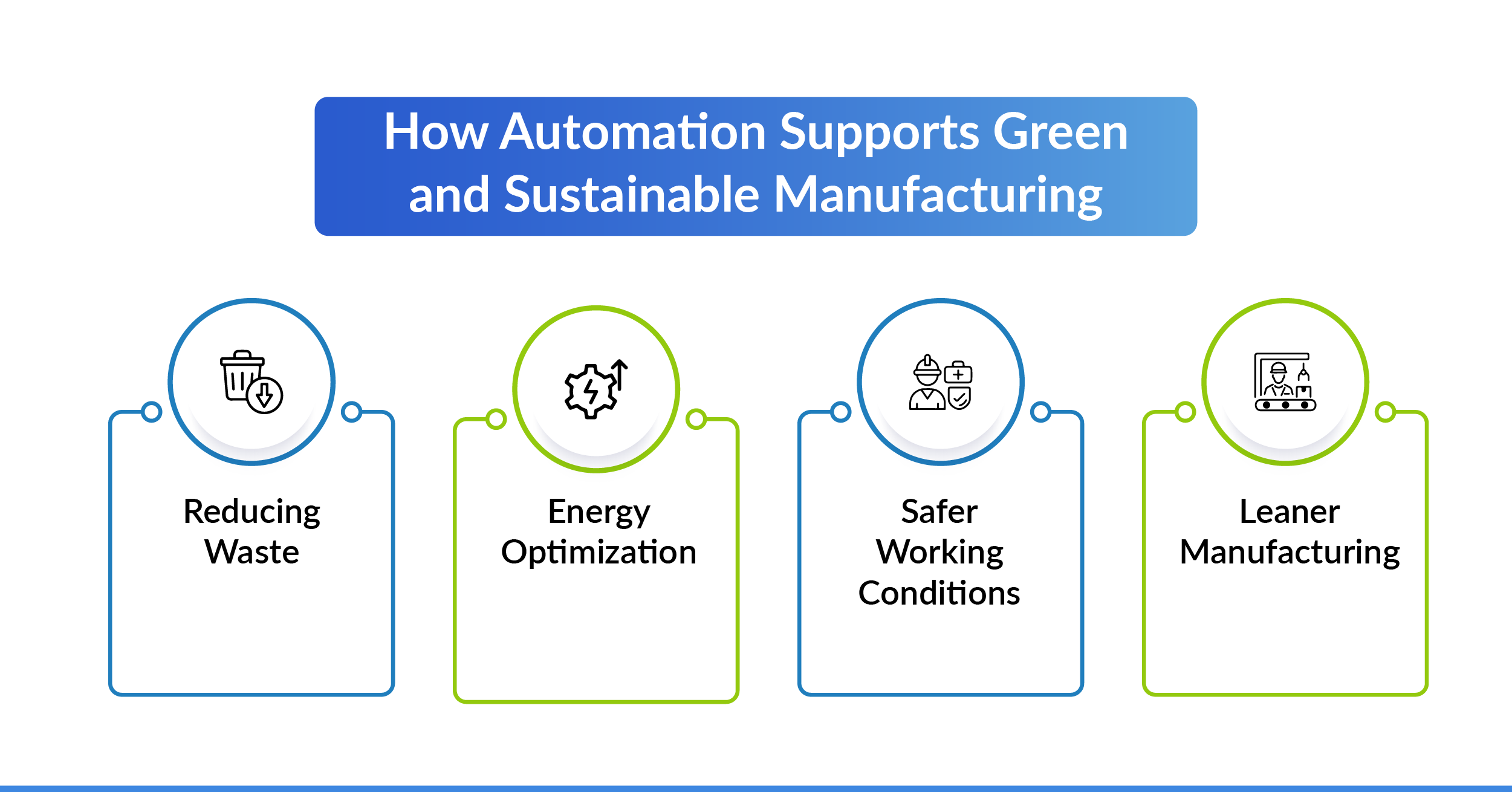

How Automation Supports Green and Sustainable Manufacturing

The automotive industry faces pressure to meet strict environmental and social standards. Automation plays a key role in

- Reducing Waste: Using materials precisely and performing automated quality checks lowers rejections.

- Energy Optimization: Smart systems adjust power use based on workload and shift patterns.

- Safer Working Conditions: Automating dangerous processes reduces risks to workers.

- Leaner Manufacturing: Just-in-time production models cut inventory levels and emissions.

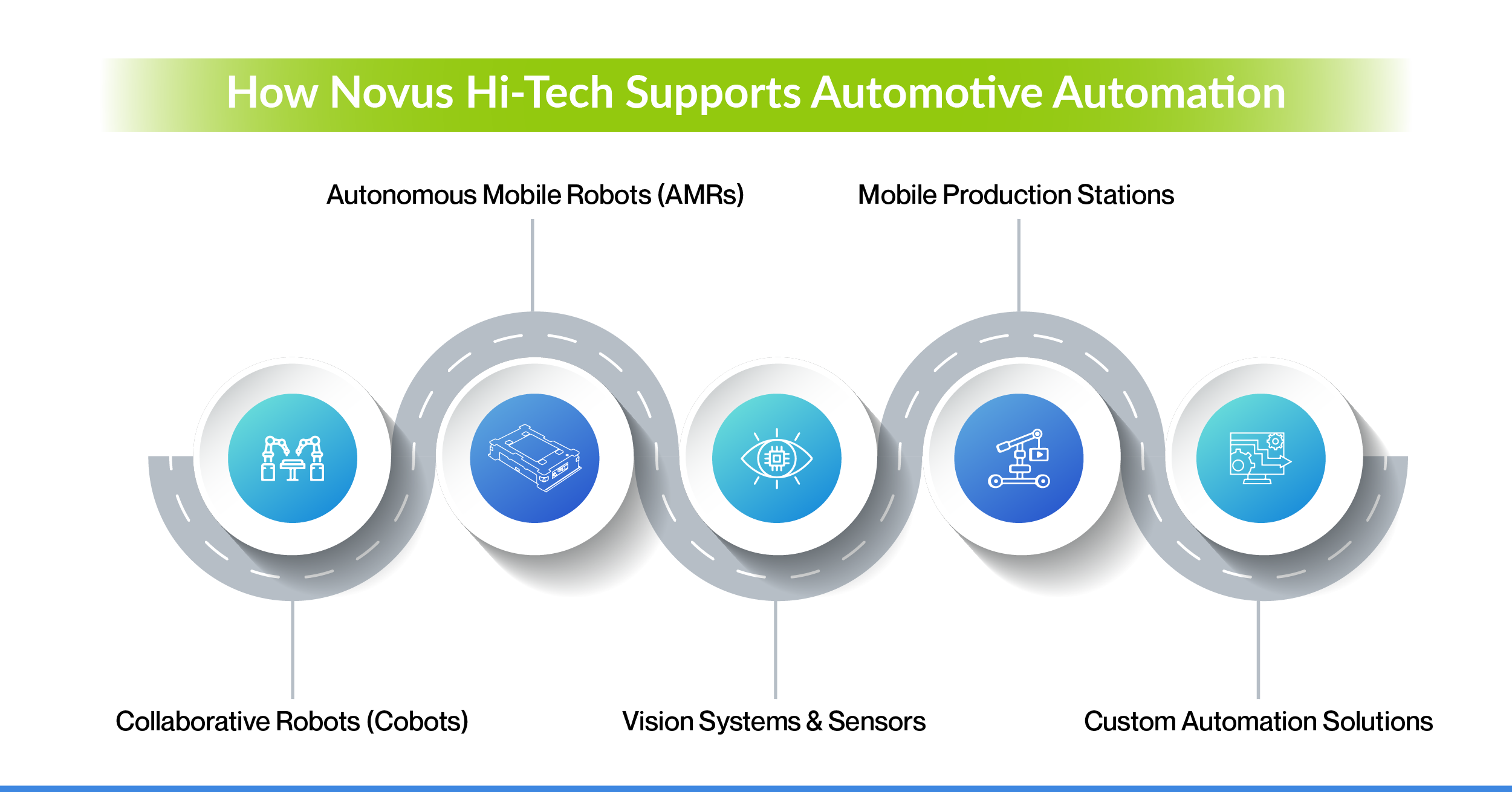

How Novus Hi-Tech Supports Automotive Automation

At Novus Hi-Tech, we design automation solutions for automotive manufacturing. Here’s how we make a difference:

- Collaborative Robots (Cobots):

They boost productivity on assembly lines while maintaining high safety standards. - Autonomous Mobile Robots (AMRs):

These robots handle materials and transfer components between lines without any human help. - Vision Systems & Sensors:

Our systems provide real-time inspections to ensure product quality and operational safety. - Mobile Production Stations:

These flexible, reconfigurable units let automotive manufacturing companies quickly adapt to new models or processes. - Custom Automation Solutions:

We provide complete robotic integration, PLC/SCADA design, and connected systems implementation that match your factory goals.

Whether you’re upgrading a single line or completely overhauling an entire plant, Novus Hi-Tech is your trusted partner for effective and sustainable automation.

Conclusion

In 2025, the automotive manufacturing industry will have a low entry barrier, but this will require smart automation in addition to innovation. Automobile manufacturing needs to be more intelligent, efficient, and environmentally friendly than ever before, thanks to cobots, AMRs, SCADA systems, and energy optimization.

The time has come for manufacturers to reassess their processes, integrate new technologies, and build productive assembly lines that will be future-ready.

FAQs

1. What is the fast 2025 future automotive industry structure?

It is hyper-connected, automated, and adaptive, with digital twins, smart supply chains, and automated lines.

2. Can automation help with automotive supply chain disruptions?

Definitely. Automated material handling with predictive demand planning can significantly improve inventory management and speed up adaptation to disruption.

3. How do you ensure worker safety when deploying robots on the factory floor?

With the use of Cobots, safety-rated sensors, interlocks, and real-time monitoring systems.

Can legacy machines be combined with modern automation systems

4. Can existing legacy machines be integrated with modern automation systems?

Absolutely. With PLC upgrades, IoT add-ons, and protocol converters, the legacy machines can interact with a smart ecosystem.