Where rapid industrialization is taking place every day, the use of high-end technology is essential rather than a luxury. Among the most ground-breaking technologies that are making a drastic change in modern industries are Autonomous Mobile Robots. These robots are making a difference in various sectors by increasing the efficiency, decreasing the costs, and increasing the standard of safety. Awareness of the various types of autonomous mobile robots and their applications is really important to businesses wanting to stay ahead in today’s competitive world, where automation has become a norm.

What are Autonomous Mobile Robots?

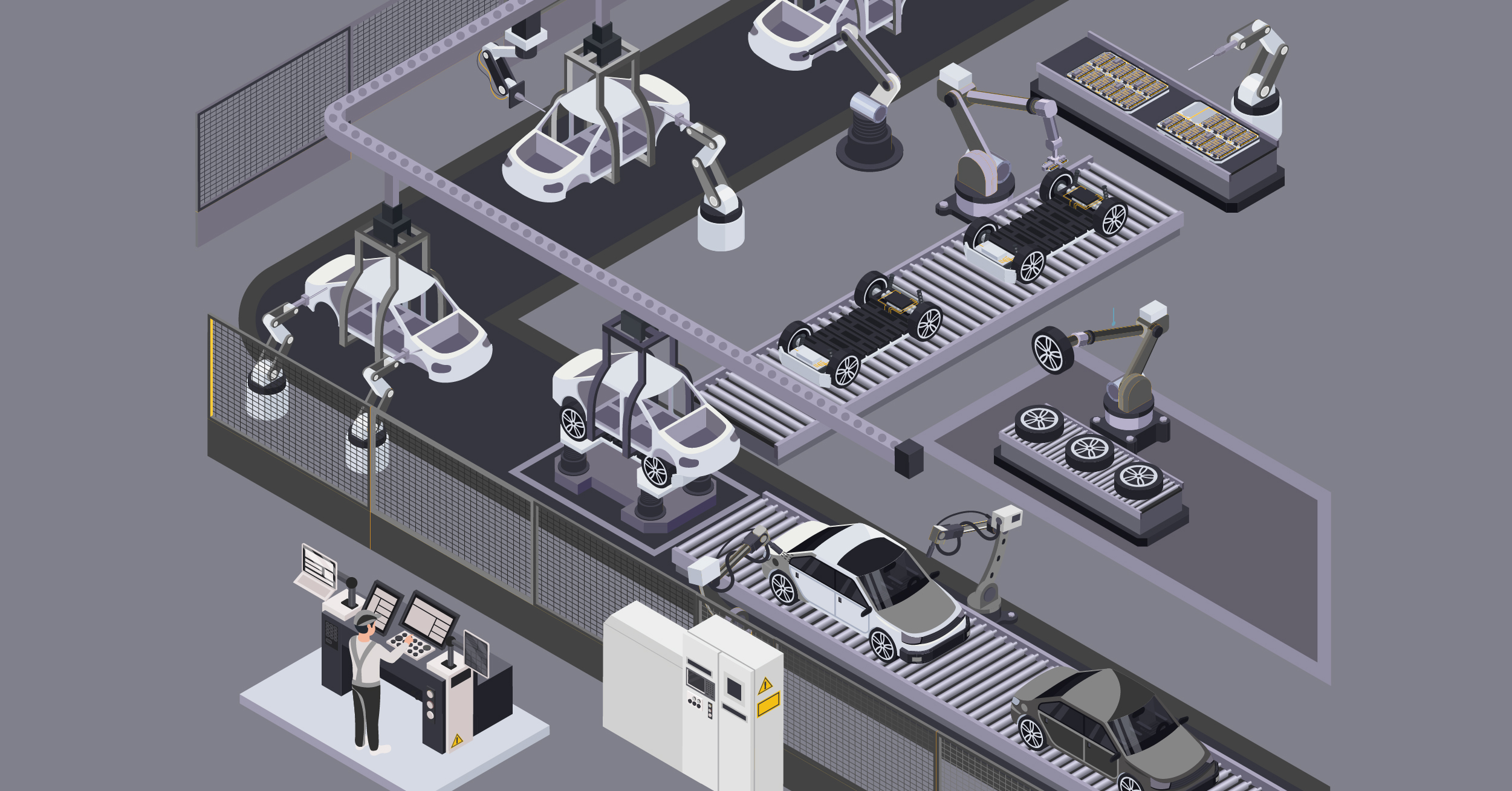

Autonomous Mobile Robots are the ones that perform in dynamic environments independently and self-reliantly, completely manipulated in their surroundings without the guidance of humans. Unlike traditional industrial robots that typically follow predefined paths or require high levels of programming, AMRs utilize advanced sensors, machine learning algorithms, and real-time processing for dynamic perception of the environment and self-localization to navigate and perform tasks in unforeseen environments. They have applications across different industries from manufacturing to logistics, health care to retail, and many others, ensuring higher operational efficiency and scalability.

AMRs are built to adapt to the environment by making decisions in real-time with the information they accumulate through various sensors. In a warehouse environment, an AMR can avoid obstacles and determine the most efficient path to reach points of interest, and it can even communicate with other robots or human workers to accomplish tasks. They must thus be flexible and adaptive for workplaces that have flexibility and autonomy.

Various Types of Autonomous Mobile Robots

It is essential to understand the various types of Autonomous Mobile Robots to help in choosing the right technology for specific industrial needs. To help you, we describe the most common types here:

Automated Guided Vehicles (AGVs)

The most well-known type of AMR is most likely Automated Guided Vehicles (AGVs). All around manufacturing and warehousing, automatically guided vehicles are used to perform the function of moving yields from one place to another. In most cases, AGVs follow a defined path which is usually marked by magnetic strips, wires, or sensors that are embedded in the floor. AGVs suit the industry where there should be a regular and high volume of material movement as, for example, in automotive manufacturing, it can carry heavy parts or assembly across production lines accurately

Autonomous Inventory Robots

Autonomous Robots in Inventory Management Many such robots are programmed to handle inventory management within warehouses and other retail environments. They scan shelves, update inventory records, identify stock discrepancies, and make sure the data is always accurate. It allows the companies to avoid the out-of-stock situation, keep stock levels at the optimal level, and reduce overall labor costs in handling the stock.

In the retail sector, inventory robots can work in non-working hours to check the stock. Hence, there is no disturbance in customer action. With the availability of stock every time, customer satisfaction will be in order, and this leads to more sales, and it increases the chance of sales.

Cleaning Robots

The cleanliness and hygiene of the industrial-cum-commercial setup are the points of focus. The cleaning robots here would come in the AMR and are meant to clean floors, windows, and all other such ground and similar surfaces. These robots have sensors and cameras equipped in them that make the robot avoid obstructions to perform the deep cleaning operation. Most applications are in the automatic cleaning of various health institutions, airports, office buildings, and also other significant sites. Cleaning robots used in industries provide not only cleanliness that is consistent but also free employees to be more productive in other complex activities, thus making the productivity of the company increase.

Security Robots

Security Robots are AMRs with cameras and sensors, and in some cases also meant for uses of artificial intelligence. Being able to keep a watchful eye on emerging threats and interior breaches, allows them to keep watch over any environment comprehensively and ever-vigilant. Besides, some of the very advanced models have a predisposition to recognize certain individuals or vehicles, which makes them ideal for a data center, warehouse, or industrial park.

Discover how different Autonomous Mobile Robots boost modern industrial efficiency.

Download our free brochure for expert insights and trends!

The Role of Autonomous Mobile Robots in Modern Industries

AMRs are now playing an increasingly vital role in modern industries, with the ability to do tasks beyond the impossible capabilities of traditional automation systems. The importance of AMRs can be summarized as follows:

Greater Operational Efficiency: AMR increases efficiency to a substantial level, as the material has to be managed, handled, and cleaned through repetition, which increases speed and ensures accuracy and repeatability, thus lifting productivity almost across the board.

Workforce Optimization: Especially for those industries in which a labor deficit is experienced, AMRs respond to the challenge by making themselves useful between those jobs that are either too dull or physically exhausting. This helps human workers focus on more complicated and creative parts of their jobs, thus optimally using human ability.

Cost Savings: AMR might demand huge investments for installation at the beginning, but in the long term, cost savings are experienced drastically. By reducing human labor in repetitive and risky work, the system saves costly accidents in the workplace and lowers operational costs.

Increased safety: AMRs make the workplace safer by taking over materials with hazardous materials, dangerous machinery, or environments that are either not good for human work or are risky or fatal. AMRs reduce human exposure to risks, making sure the company maintains good safety standards and abides by regulatory requirements.

Scalability: For growing organizations, there is always a demand for more nimbleness of their processors. AMRs can be easily scaled to stand better production or service levels without incurring significant infrastructure or labor.

Considering the above-noted advantages, it would be evident that AMRs are not a trend but rather the crucial building block of the future of industrial operations. Their capacity to integrate across multiple industrial processes and open new frontiers of efficiency and safety supports significantly beneficial changes in the competitive market.

Conclusion

Autonomous Mobile Robots are opening new industrial applications by realizing innovative, proficient, and scalable solutions. The market today offers versatile categories of these mobile robots, all tailored to different specific industrial challenges, from traditional uses of AGVs in manufacturing to security robots in high-risk environments. Businesses interested in how autonomous, agile mobile robots bring value to industrial operations should better understand the different categories and their benefits.

Novus Hi-tech is a trusted resource for the optimization of AMRs, having valuable work approaches on how industries can easily integrate advanced technologies to operate. Be it productivity, cost reduction, or safety, Novus Hi-tech is well-equipped to walk the journey with you. Reach out to us and learn how to unlock full potential in your industry.