Transitioning from Automated to Autonomous: Understanding the Distinction

The terms ‘automated’ and ‘autonomous’ are frequently mixed up and used interchangeably, yet they possess distinct and inherent differences in meaning.

Automated: This concept revolves around the utilization of computer-controlled machinery to execute predefined tasks, often operating with minimal or no human intervention.

Autonomous: In contrast, this designation applies to machines equipped with the ability to make informed decisions in the face of unforeseen or novel situations. These advanced systems may also possess the capability to acquire knowledge and adapt as they encounter unfamiliar scenarios.

Discover the key differences between AGVs and AMRs to make informed decisions.

Download our free brochure for expert insights and trends!

AGV vs AMR

AGVs and AMRs, which stand for Automated Guided Vehicles and Autonomous Mobile Robots respectively, are often sources of confusion due to their distinct operational technologies. These systems diverge significantly in terms of their functionalities and potential use cases.

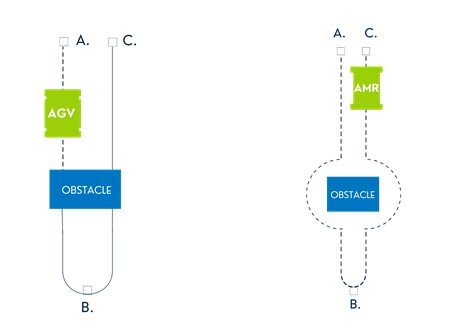

Automated Guided Vehicle (AGV): An AGV stands as an unmanned electric vehicle directed by pre-programmed software, entrusted with the responsibility of transporting materials within a specified facility. AGVs depend on an array of guidance systems, including magnetic tape, beacons, barcodes, or predefined laser pathways, enabling them to traverse predetermined routes within a controlled environment. Laser-based sensors detect obstacles along their path and autonomously initiate halts to ensure safety.

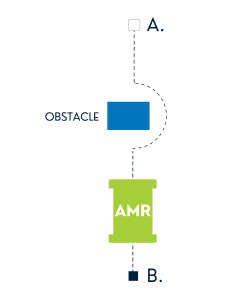

Autonomous Mobile Robot (AMR): An AMR is a robot capable of operating without direct human intervention or predefined scripts to control its movements, including steering, acceleration, and braking. In industrial settings, AMRs employ laser-based perception and navigation algorithms, enabling them to navigate dynamically throughout facilities without the need for fixed infrastructure. The integration of machine learning capabilities empowers AMRs to continually enhance their efficiency and precision when encountering novel situations.

The AMR: Advancing Beyond the AGV

The landscape of automated material transport has undergone a transformation, driven by the rapid progress in sensor technology and the harnessing of big data capabilities. Next-generation autonomous solutions are reshaping traditional AGV technologies, offering five key advantages:

1. FLEXIBLE AND VERSATILE

AGVs follow predefined paths using lasers, beacons, barcodes, or magnetic tape.

Impacts:

- Multiple AGVs are needed for various applications.

- Ongoing infrastructure maintenance is necessary.

- Minor debris in the laser’s view halts the vehicle until manually cleared.

AMRs navigate without external infrastructure, simplifying implementation.

Impacts:

- One AMR serves multiple applications.

- Encourages 5S standards for clean aisleways.

- AMRs autonomously avoid obstacles, reducing downtime.

- Customizable parameters for navigating different zones.”

2. EASILY SCALABLE

AGVs can be integrated into a facility provided that the layout meets the infrastructure requirements for AGV implementation.

Impacts:

– Requires resource allocation for facility planning, infrastructure changes, maintenance, and training.

– Facility layout must accommodate AGV requirements.

AMRs operate without the need for external infrastructure for navigation, streamlining implementation, and enabling high scalability.

Impacts:

– Can add more AMRs in <1 day using a centrally controlled map.

– No need for infrastructure changes, facility planning, or additional training.

– Eliminates the need for outsourcing work to third-party vendors for changes or expansions.

3. REDEPLOYABLE

Moving an AGV is like installing a new AGV system, it demands significant resources.

Impacts:

- Fixed infrastructure with rigid and costly changes.

- Need for multiple systems despite seasonal variations.

AMRs are easily redeployed between plants or within the same plant with minimal setup time managed by the customer.

Impacts:

- Sharing units between facilities to meet seasonal demands.

- Increasing throughput in bottlenecked areas by redeploying underutilized assets.

- Fewer units needed for purchase, as AMRs can be shared resources.”

4. INTELLIGENT AGV

AGVs lack intelligence due to their infrastructure-dependent nature, resulting in:

Impacts:

– Limited real-time KPI visibility for operators.

– Static stack lights and sounds, regardless of changing environments.

– Inability to reverse or choose alternate routes.

– Challenges in seamless integration with other solutions.

AMRs boast onboard intelligence, offering advantages such as:

Impacts:

– Adaptive route optimization in dynamic environments.

– Safe collaboration with plant personnel.

– Intuitive lights and sounds resembling vehicles for easy communication.”

5. Usability Comparison

AGVs are intended for performing straightforward tasks, but their setup and operation can be intricate, cumbersome, and come with significant costs.

Impacts:

– AGVs perform simple tasks but involve complex, costly, and cumbersome setup and operation.

– Requires trained personnel or engineers for operation.

– System changes necessitate facility infrastructure updates and additional staff training.

The implementation process of AMR involves mapping the facility once using a robot and subsequently configuring zones and points of interest on the map within the fleet manager.

Impacts:

– Setup is customer-driven and utilizes a user-friendly point-and-click interface.

– Updates and modifications can be made by in-house personnel.

– Adaptations to production lines or distribution layouts are straightforward to implement.

Conclusion

In conclusion, while both Automated Guided Vehicles (AGVs) and Autonomous Mobile Robots (AMRs) serve similar purposes in industrial settings, their operational distinctions are crucial. AMRs, with their ability to navigate autonomously without the need for fixed infrastructure, offer a more flexible, adaptable, and efficient solution compared to traditional AGVs. Their advanced sensors and AI algorithms enable them to navigate dynamic environments, optimize routes, and perform tasks with greater precision. For businesses seeking enhanced productivity, scalability, and cost-effectiveness, AMRs present a superior alternative.To explore how AMRs can revolutionize your operations, contact us today for a tailored solution that meets your needs. Let’s navigate the future together.

AGVs vs Traditional Equipment

- Automated Guided Vehicle Equipment: Fully automated equipment that requires minimal input from human employees.

Traditional Equipment: Equipment that requires a manual operation which depends on a workforce. Safety

- Automated Guided Vehicle Equipment: Equip the automation with built-in sensors and capable of avoiding collision and potential danger.

Traditional Equipment: Comparatively to the automation, which uses sensors, there is a greater chance of human error, which could lead to potential workplace hazards.Cost Efficiency

- Automated Guided Vehicle Equipment: Although automated equipment may require higher-than-usual initial costs, automated equipment is a cost-effective long-term investment and lowers operational costs over time.

Traditional Equipment: Operational costs or expenses tend to be significantly higher when using manual equipment than using

- Automated Guided Vehicle Equipment, although the manual equipment may have a lower initial cost associated with its adoption and use.

- Scalability Automated Guided Vehicle Equipment: Automated equipment connected and operated by software is more easily scaled due to it being a digital solution.

Traditional Equipment: The expansion of workforce use or additional use of traditional equipment requires the addition of labor and equipment to reach more workers or higher project demand.

- Integration Automated Guided Vehicle Equipment: Automated systems also seamlessly integrate with existing internal digital systems, and collects and tracks data for further use.

Traditional Equipment: It is limited in its integration with technology and further lacks data tracking capabilities.