Automotive manufacturing plants are undergoing rapid changes at present, driven by global factors such as globalization, technological advancements, and shifting consumer expectations. Automakers will need to make similar changes to their production methods, such as smarter, leaner, more flexible, and more sustainable production, through investments in their plants. As the car industry evolves, it will also be crucial to be aware of the significant changes currently underway in the automotive manufacturing industry to position yourself for competitive and strategic success in the future.

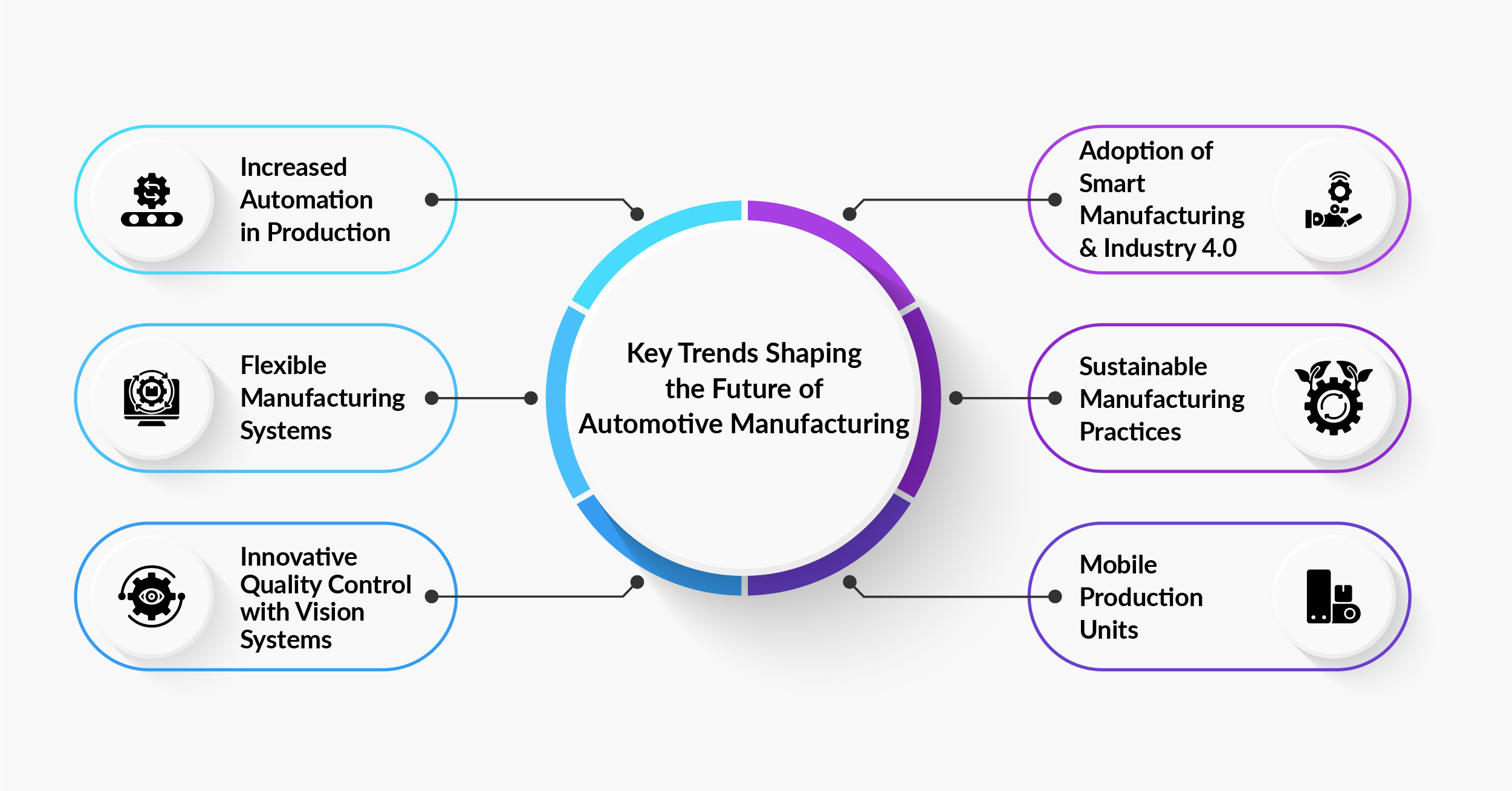

Key Trends Shaping the Future of Automotive Manufacturing

Increased Automation in Production

Implementing automated systems using robotics is replacing the workforce and enhancing the speed, precision, and certainty of quality.

Adoption of Smart Manufacturing & Industry 4.0

Connected devices, IoT, and real-time data analytics technologies provide predictive maintenance and real-time information on the factory floor to improve the smartness and efficiency of decisions.

Flexible Manufacturing Systems

Manufacturers are using technologies that make it easy to switch between models and sizes of batches, which helps implement Mass Customization with greater flexibility and leaner production.

Sustainable Manufacturing Practices

Car plants are maximizing sustainability targets with the implementation of lightweight materials, sustainable materials, energy-efficient machines, and waste elimination to appeal to consumers with green impulse buying interests.

Innovative Quality Control with Vision Systems

AI-powered vision systems and sensors that provide real-time defect detection and quality inspections during production will help reduce recalls and create high-quality products.

Mobile Production Units

Mobile production workstations help provide a quick adjustment to workflow, supporting lean manufacturing and providing momentum to be responsive to market input changes.

Discover how Automotive Automation transforms production efficiency.

Download our free brochure for expert insights and trends!

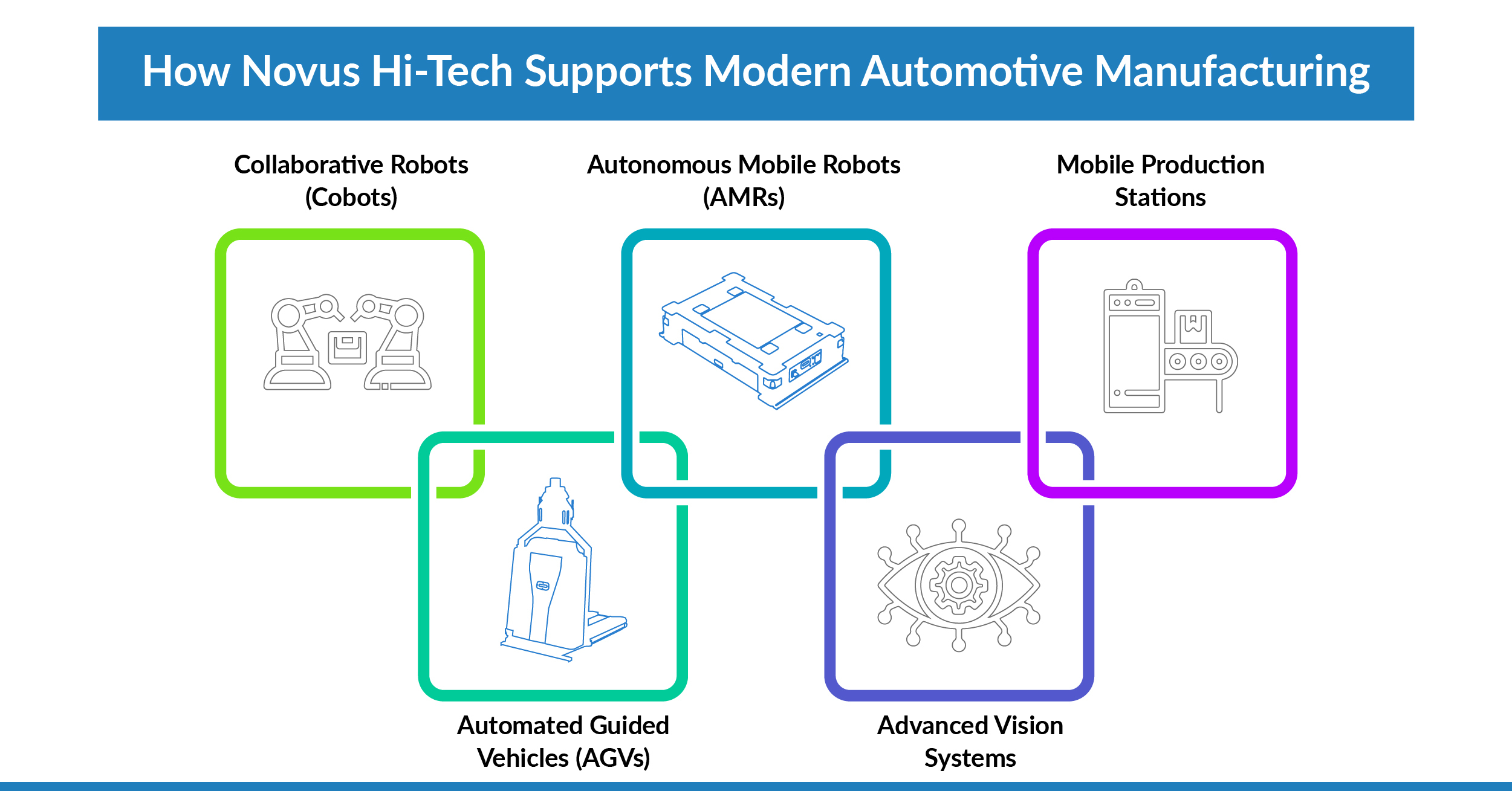

How Novus Hi-Tech Supports Modern Automotive Manufacturing

Novus Hi-Tech is leading the way to make auto manufacturing more intelligent, efficient, and better prepared for the future. They have a ton of great tools that help automotive manufacturers to trends in the auto industry.

Collaborative Robots (Cobots): Novus Hi-Tech has the latest cobots that work and communicate safely with human workers. Cobots allow for enhanced productivity with no safety concerns for the human operator.

Automated Guided Vehicles (AGVs): AGVs move material in and around the auto manufacturing facility, resulting in enhanced productivity, less manual handling of parts, and time savings.

Autonomous Mobile Robots (AMRs): AMRs are flexible, on-demand logistics for manufacturing. With AMRs, manufacturers can take full advantage of the transportation capacity for their local operations.

Advanced Vision Systems: Novus Hi-Tech has precision vision systems and sensors that add exceptional quality control function to manufacturing processes. Vision systems can even detect defects, and you can modify your process in real-time.

Mobile Production Stations: Mobile production stations provide scalable and adaptable production spacing that can provide a quick/changeover and allow for lean manufacturing.

Integrating Novus Hi-Tech’s advanced technologies ensures automotive manufacturers are future-ready and productive.

Conclusion

The automotive manufacturing industry is undergoing transformation from trends of automation, smart manufacturing, flexibility, sustainability, and advanced quality. Moving forward in the construction of the auto industry, manufacturers must be adaptive and innovative. Novus Hi-Tech provides a solution set for automotive manufacturers that wish to adopt these trends to maintain pace with their competitors, constructing their innovative production lines. To learn more about how Novus Hi-Tech can change your automotive manufacturing operations, take a look at their website today.

FAQs

1. How can automotive manufacturers reduce their carbon footprint?

Automotive manufacturers’ plants can reduce their carbon footprint by using energy-efficient equipment, lightweight and recyclable materials, minimizing waste, and implementing renewable energy into the production processes.

2. How do AGVs and AMRs support just-in-time manufacturing?

AGVs and AMRs streamline the movement of material within automotive manufacturing plants to deliver components to the production line quickly, decrease inventory levels, and operations to support just-in-time manufacturing.

3. Can legacy automotive plants transition smoothly to smart manufacturing?

Yes, legacy automotive manufacturers can transition to smart manufacturing slowly and progressively incorporate IoT devices, automation systems, data analytics tools, etc, in their manufacturing operations and as a result increase efficiency for their facility.

4. Are mobile production stations suitable for high-volume manufacturing plants?

Yes, mobile production stations are very versatile and can easily be adapted to accommodate high-volume manufacturing. They allow for fast changes in workflow configurations and are perfect for lean, flexible production environments.